Manufacturing method of light-emitting device with crystal coated light emitting diode

A technology of light-emitting diodes and light-emitting devices, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., and can solve problems such as lower yield rate and cumbersome manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

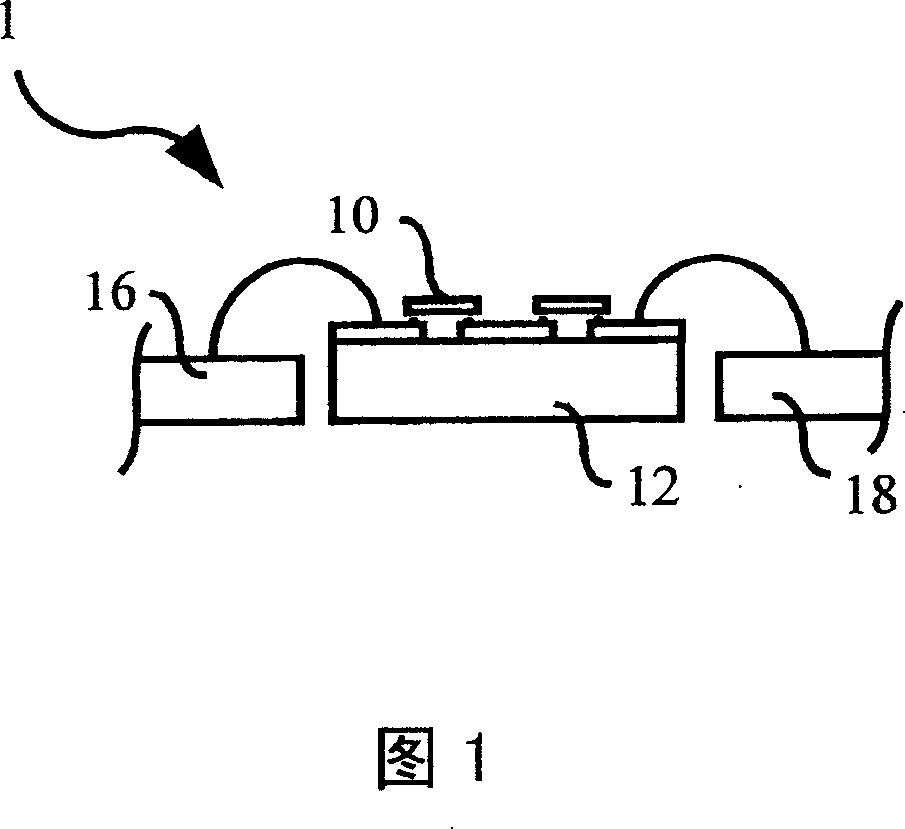

[0021] Aiming at the problems of cumbersome manufacturing process, poor yield rate and poor heat dissipation caused by the luminous body in the prior art, the present invention proposes a manufacturing method of a light-emitting device with flip-chip light-emitting diodes.

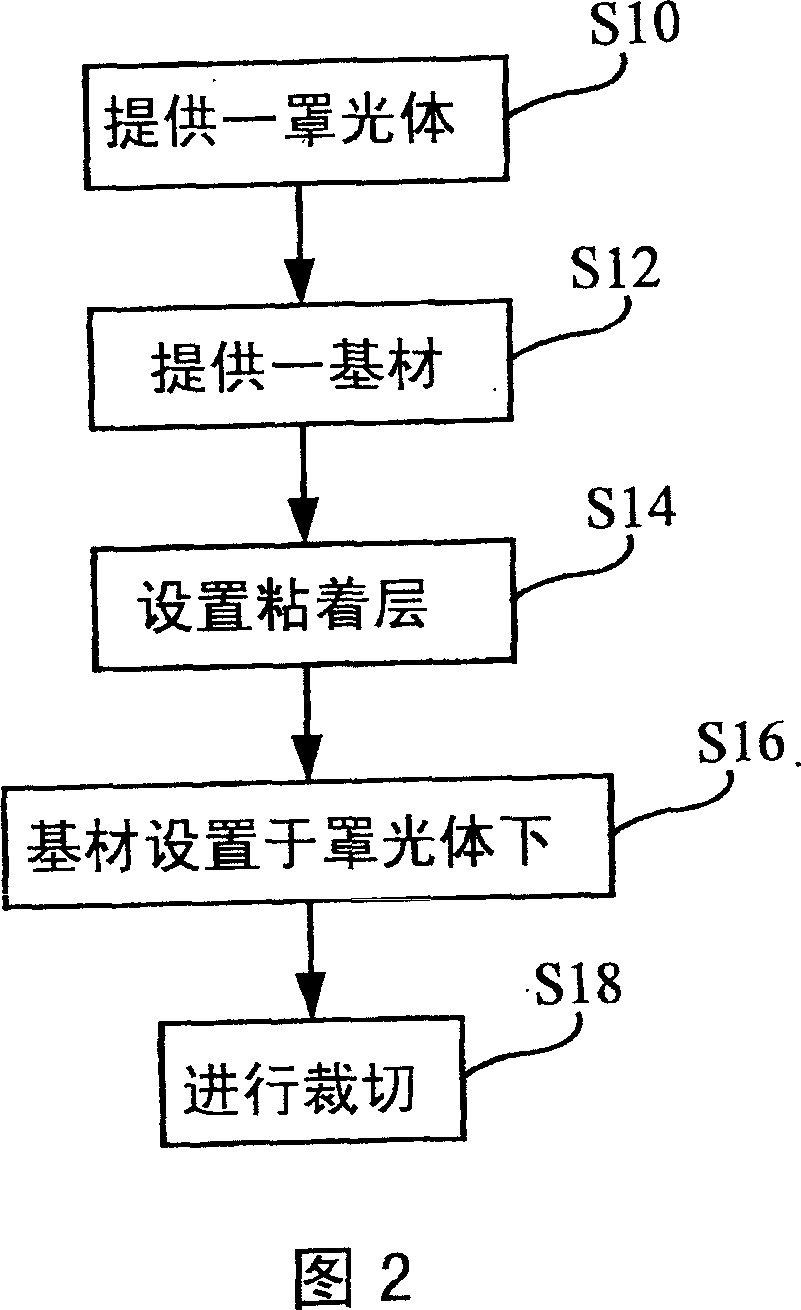

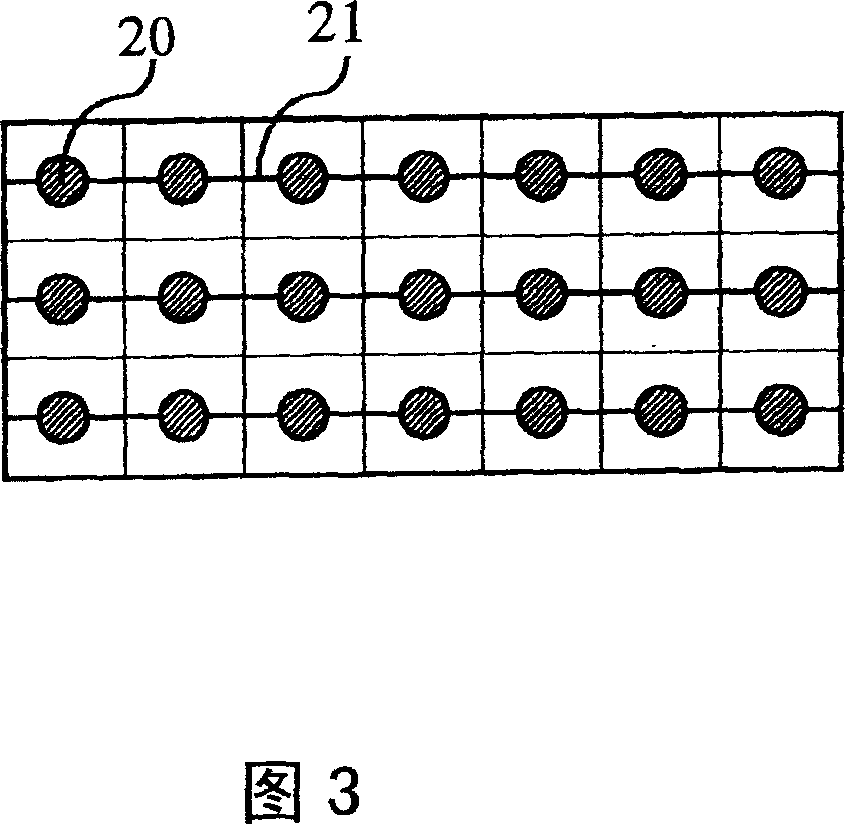

[0022] Fig. 2 shows the flow chart of manufacturing the light-emitting device with flip-chip light-emitting diodes of the present invention. At first, as step S10, a masking body group (strap) is provided, and please refer to the schematic diagram shown in Fig. 3 at the same time, the masking body The group includes several light-shielding bodies 20, and a metal lead frame 21 is arranged in each light-shielding body 20, and each two light-shielding bodies 20 are connected to each other through the metal lead frame 21, and then as in step S12, a base material, such as a silicon (Si) substrate, on which several light-emitting diodes are arranged as light-emitting elements, and these light-emitting diodes are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com