Manufacturing process of fingerprint lock chip

A manufacturing process and fingerprint lock technology, applied in the field of fingerprint lock chip manufacturing process, can solve the problems of reducing the height of the module, not seeing the fingerprint lock chip, etc., to improve product reliability, high-efficiency integrated fingerprint recognition, total The effect of thickness reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

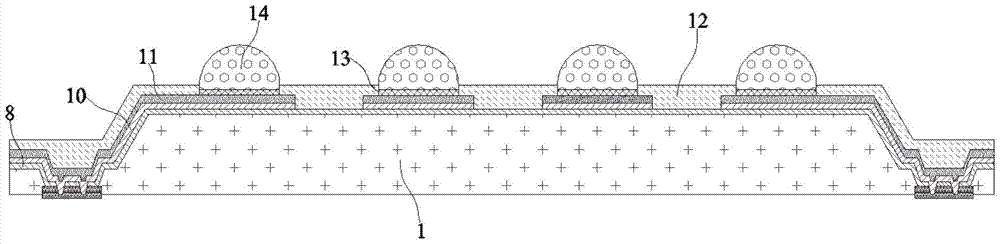

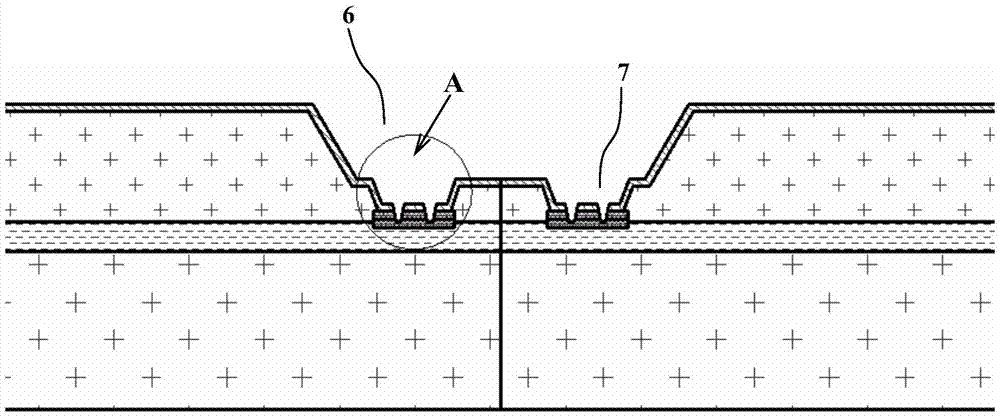

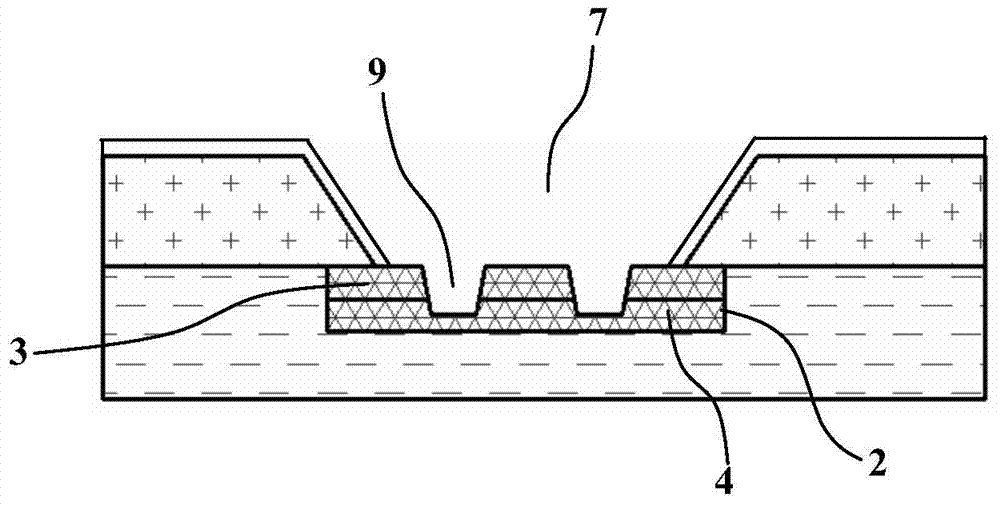

[0033] Embodiment 1: A manufacturing process of a fingerprint lock chip, the upper surface of the fingerprint lock chip 1 is distributed with several blind holes 2, and there is an aluminum pad 3 in the blind hole 2 of the fingerprint lock chip 1, the aluminum pad 3 extends from the bottom of the blind hole 2 to the middle of the blind hole 2, the surface of the aluminum pad 3 in the blind hole 2 is filled with a nickel metal layer 4, and the nickel metal layer 4 extends from the middle of the blind hole 2 to the upper surface of the fingerprint lock chip 1 and forms a convex to form a pad thickening part 5;

[0034] The lower surface of the fingerprint lock chip 1 and the area opposite to the blind hole 2 have a first tapered blind hole 6 and a second tapered blind hole 7 from outside to inside, and the second tapered blind hole 7 is located in the first tapered blind hole. At the bottom of the hole 6, the cross section of the first tapered blind hole 6 and the second tapered...

Embodiment 2

[0045] Embodiment 2: A manufacturing process of a fingerprint lock chip, the upper surface of the fingerprint lock chip 1 is distributed with several blind holes 2, and there is an aluminum pad 3 in the blind hole 2 of the fingerprint lock chip 1, the aluminum pad 3 extends from the bottom of the blind hole 2 to the middle of the blind hole 2, the surface of the aluminum pad 3 in the blind hole 2 is filled with a nickel metal layer 4, and the nickel metal layer 4 extends from the middle of the blind hole 2 to the upper surface of the fingerprint lock chip 1 and forms a convex to form a pad thickening part 5;

[0046] The lower surface of the fingerprint lock chip 1 and the area opposite to the blind hole 2 have a first tapered blind hole 6 and a second tapered blind hole 7 from outside to inside, and the second tapered blind hole 7 is located in the first tapered blind hole. At the bottom of the hole 6, the cross section of the first tapered blind hole 6 and the second tapered...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com