Fingerprint lock identification module package structure

A technology of fingerprint identification and packaging structure, which is applied in the direction of character and pattern recognition, instruments, electrical components, etc., can solve the problems of reducing the height of modules, improve product reliability, enhance data processing speed and electrical stability, and manufacture The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

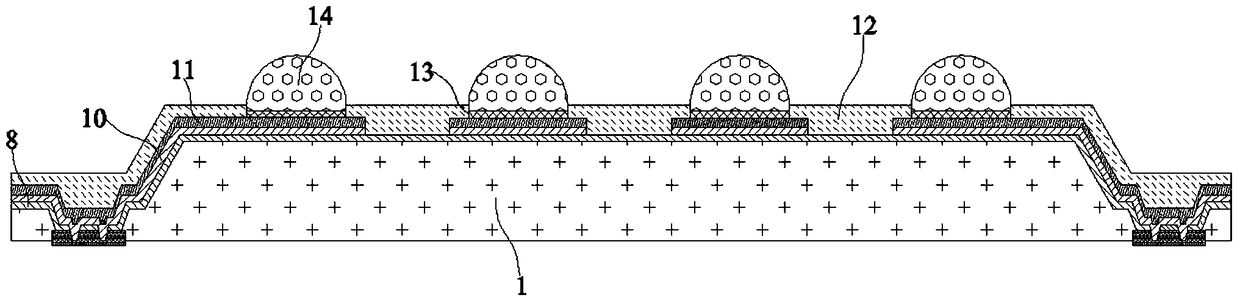

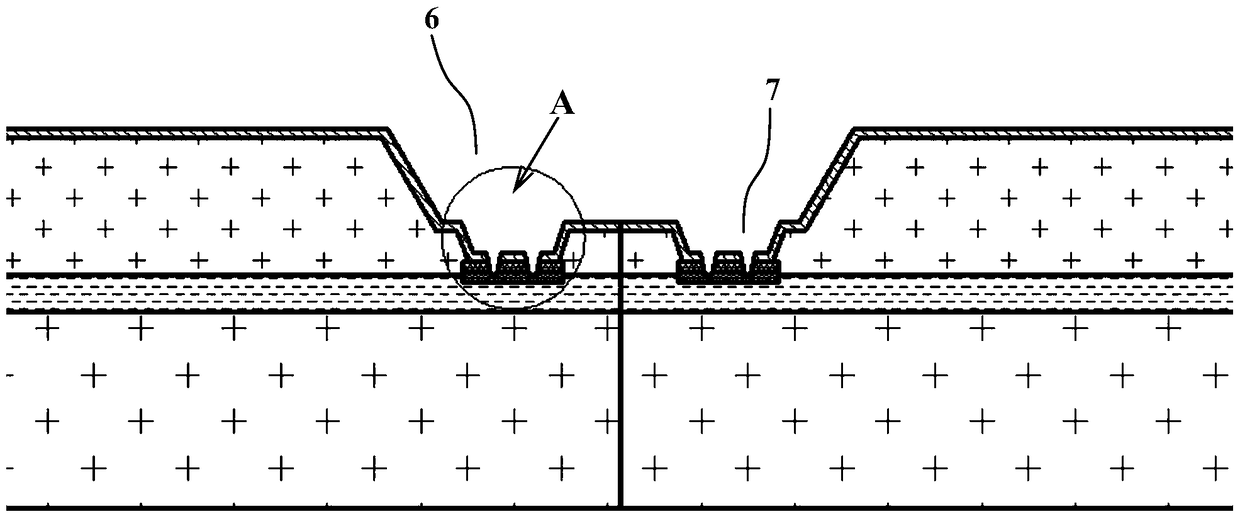

[0026] Embodiment 1: A fingerprint lock identification module packaging structure, including a fingerprint identification chip 1, a ceramic cover plate 15, a PCB board 16 and a data processing chip 17, between the sensing area of the fingerprint identification chip 1 and the ceramic cover plate 15 A high dielectric constant layer 18 is provided, and the PCB board 16 and the data processing chip 17 are electrically connected to the fingerprint identification chip 1;

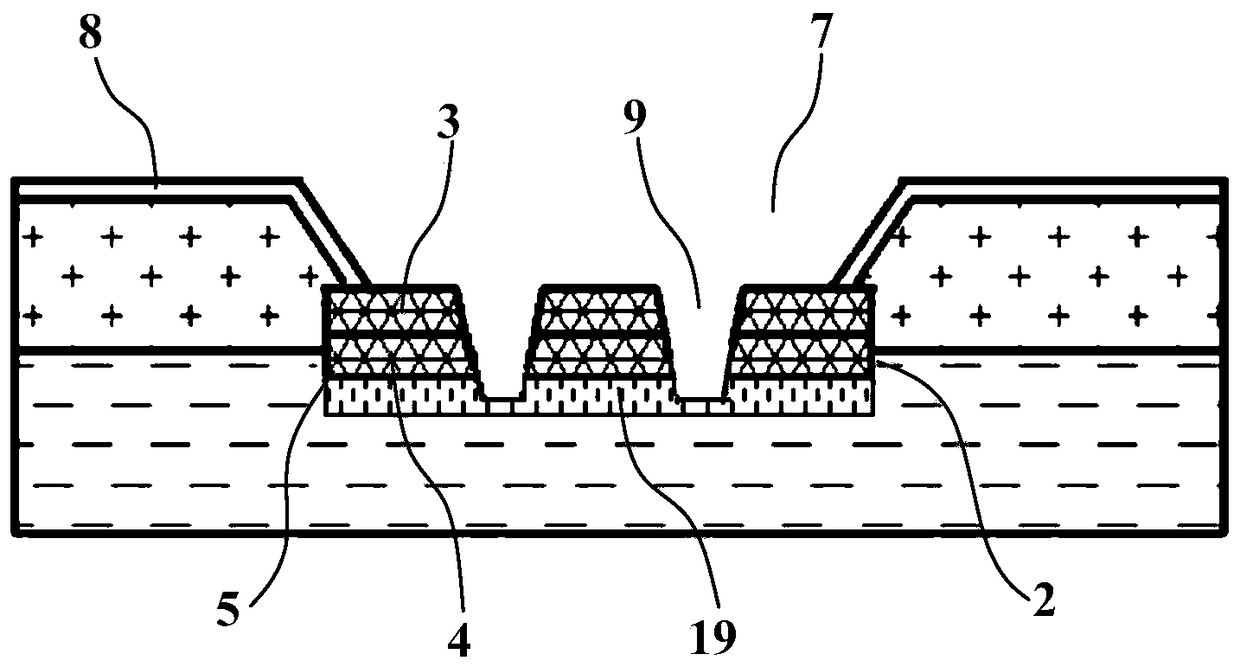

[0027] There are several blind holes 2 distributed on the upper surface of the fingerprint recognition chip 1, and the blind holes 2 of the fingerprint recognition chip 1 have an aluminum pad 3, and the aluminum pad 3 extends from the bottom of the blind hole 2 to the middle of the blind hole 2, The surface of aluminum pad 3 in blind hole 2 is covered with nickel metal layer 4 and gold-palladium alloy layer 19 in turn. The thick part 5, the gold-palladium alloy layer 19 is located on the surface of the pad thick...

Embodiment 2

[0031] Embodiment 2: A fingerprint lock identification module packaging structure, including a fingerprint identification chip 1, a ceramic cover plate 15, a PCB board 16 and a data processing chip 17, between the sensing area of the fingerprint identification chip 1 and the ceramic cover plate 15 A high dielectric constant layer 18 is provided, and the PCB board 16 and the data processing chip 17 are electrically connected to the fingerprint identification chip 1;

[0032] There are several blind holes 2 distributed on the upper surface of the fingerprint recognition chip 1, and the blind holes 2 of the fingerprint recognition chip 1 have an aluminum pad 3, and the aluminum pad 3 extends from the bottom of the blind hole 2 to the middle of the blind hole 2, The surface of aluminum pad 3 in blind hole 2 is covered with nickel metal layer 4 and gold-palladium alloy layer 19 in turn. The thick part 5, the gold-palladium alloy layer 19 is located on the surface of the pad thick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com