Desk-type small Twin-shaft machinery loading device

A mechanical loading device, small-scale technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of increasing the difficulty of clamping and adjusting the specimen, deviation of the specimen center, time error, etc., and achieve the goal of reducing consistency Demanding, easy to achieve, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

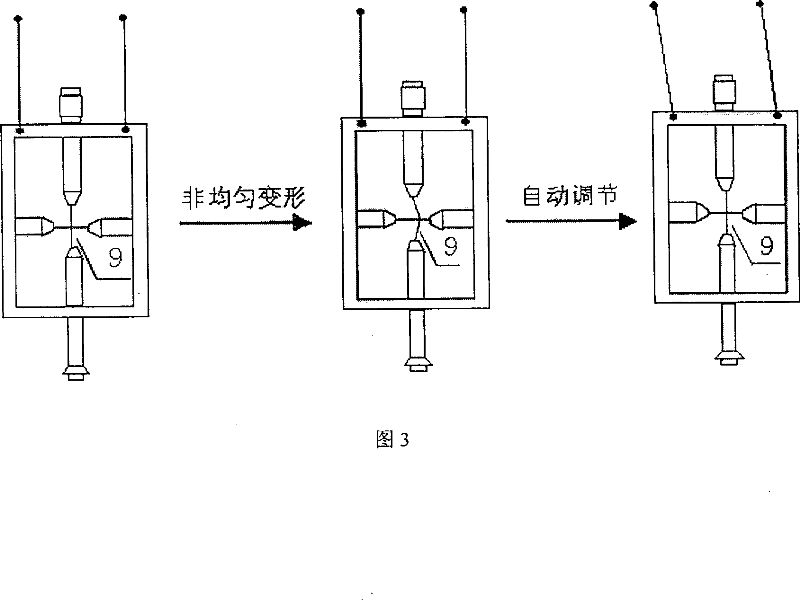

[0016] Fig. 2 is a kind of desktop small-sized two-axis mechanical loading device provided by the present invention, which device includes a composite frame and a loading transmission system; the composite frame includes a main frame 1, an intermediate suspension frame 2 and an internal suspension frame 3; the described The upper side and the left and right sides of the main frame are provided with strip-shaped piercing openings 15, the upper and lower sides of the middle suspension frame are provided with strip-shaped piercing openings 15, and the left and right sides are provided with circular through holes 16. The left and right sides of the internal suspension frame of the inner suspension frame are provided with strip-shaped piercing openings 15, and the upper and lower sides are provided with circular through holes 16; the described loading transmission system includes a horizontal direction loading device and a vertical direction loading device, and the described horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com