Compressor wheel assembly

A technology for compressors and compressor housings, which is applied in the direction of engine components, pump components, rotary piston type/swing piston type pump components, etc., which can solve problems such as difficult concentricity, and achieve the effect of improving the ability to carry torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

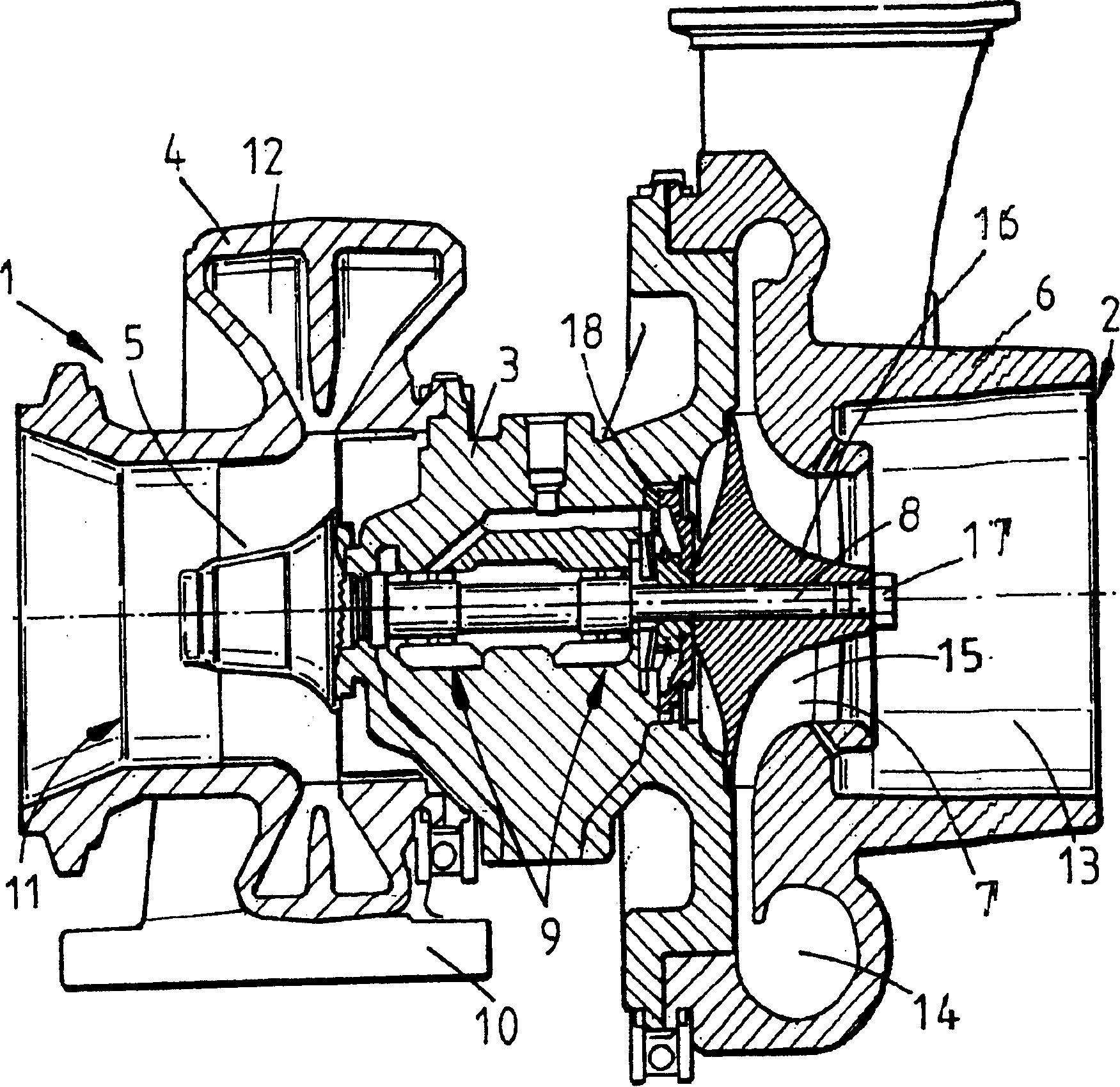

[0012] The illustrated turbocharger comprises a turbine 1 connected to a compressor 2 via a central bearing chamber 3 . The turbine 1 comprises a turbine housing 4 which accommodates a turbine wheel 5 . Similarly, the compressor 2 comprises a compressor housing 6 housing a compressor wheel 7 . The turbine wheel 5 and the compressor wheel 7 are mounted on opposite ends of a common shaft 8 which is supported by a bearing assembly 9 located in the bearing chamber 3 .

[0013] The turbine housing 4 is provided with an exhaust gas inlet 10 and an exhaust gas outlet 11 . The inlet 10 directs the incoming exhaust gases into an annular intake chamber 12 around the turbine wheel 5 . Exhaust gases flow through the turbine and flow into the exhaust outlet 11 through a circular exhaust opening coaxial with the turbine runner 5 . The rotation of the turbine wheel 5 drives the rotation of the compressor wheel 7 , which sucks in air through the axial inlet 13 and delivers the compressed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com