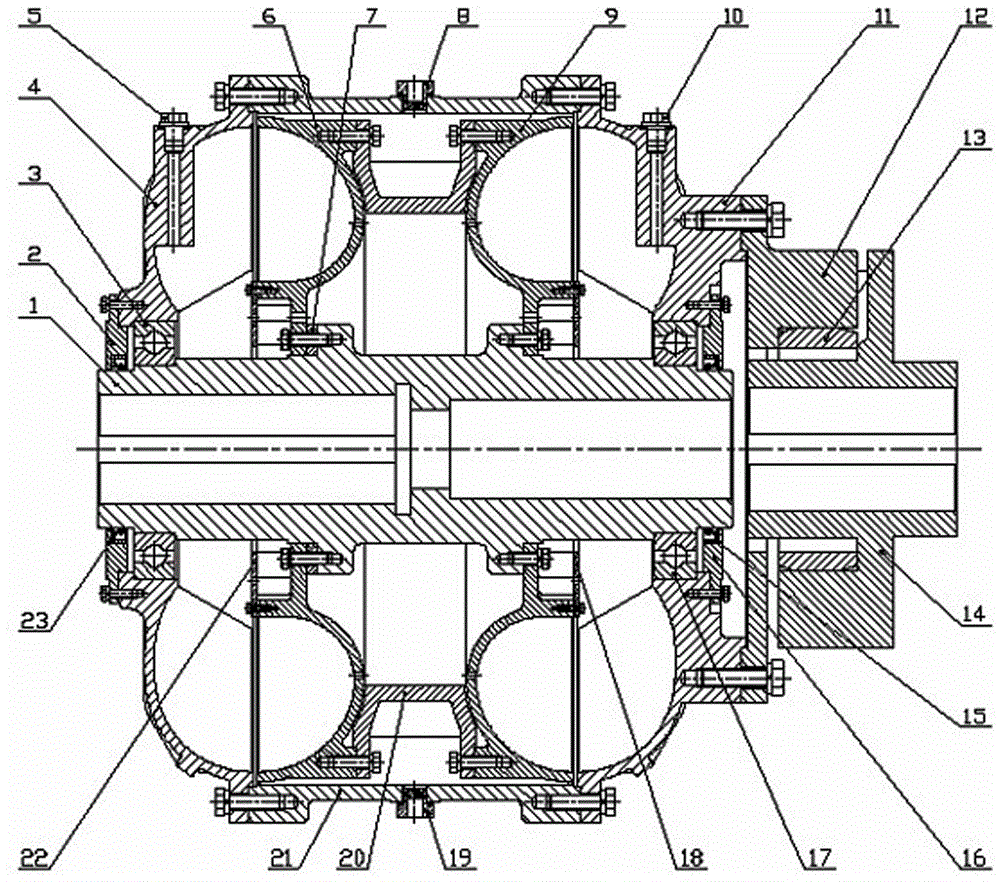

A dual-chamber torque-limiting hydraulic coupling

A hydraulic coupling and torque-limiting technology, which is applied to fluid transmission devices, belts/chains/gears, mechanical equipment, etc., can solve problems such as complex structures and large axial dimensions, achieve stable torque changes, and reduce radial Dimensions, the effect of increasing the moment limiting capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] The left and right pump wheels 6, 9 and the left and right turbines 4, 11 of the present invention are all cast with resin sand technology for casting aluminum; There are flow holes φD1 and φD2. The left and right pump wheels 6 and 9 are connected by bolts through the auxiliary chamber shell 20, and the joint surface is coated with sealant for sealing. A reinforcing rib is welded on the outer side of the auxiliary chamber shell. The left pump wheel 6 and the right pump wheel 9 are connected to the input shaft sleeve 1 with bolts. In order to avoid over-positioning of the shaft shoulders of the left and right pump wheels and the input shaft sleeve, an adjusting washer 7 is installed at the contact point between the left pump wheel and the shaft shoulder. Adjust washer thickness to avoid over-seating. Baffle plates 22 and 18 are respectively housed on the left and right pump wheels, and are fastened with bolts. The cavity between the left and right pump wheels, the aux...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com