Combined pulse charging method and apparatus

A charging method and combined pulse technology, applied in the direction of secondary battery charging/discharging, current collectors, electric vehicles, etc., to achieve the effects of improving efficiency, reducing pollution pressure, and reducing scrap volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

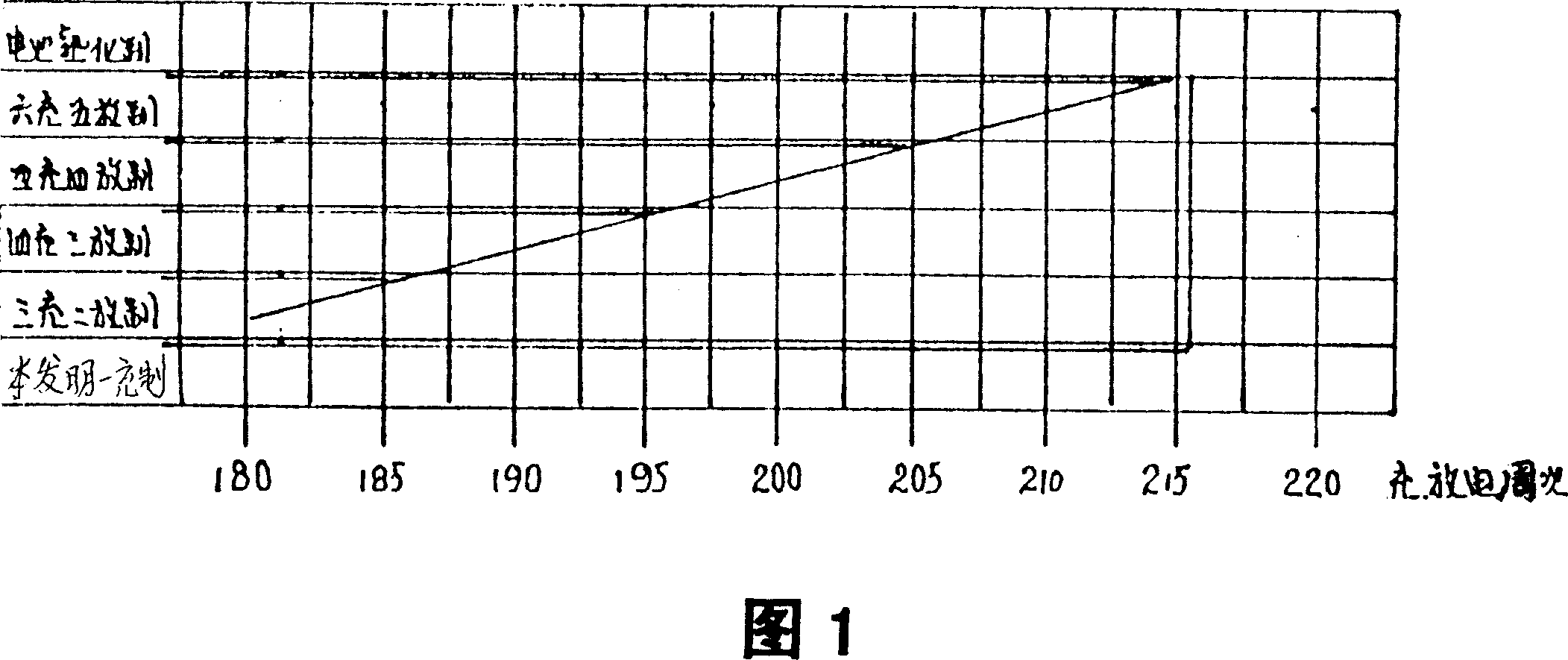

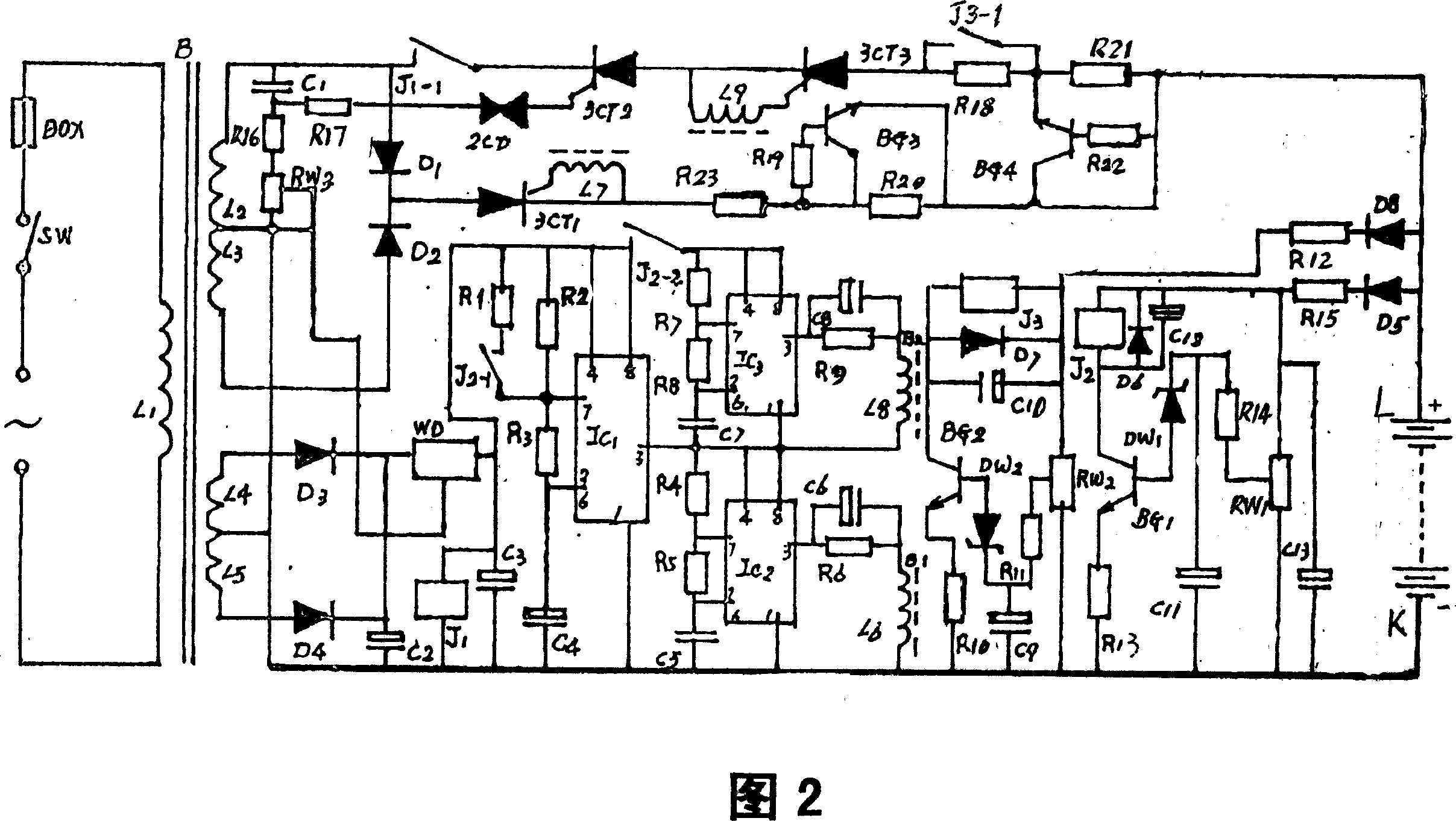

[0022] The present invention fully considers the characteristics of the electrochemical reaction between the current positive charging and positive and negative combined pulse charging between the battery plate and the dielectric, and changes the aging and charging process in the biochemical state after assembly from the current general six-charging and five-discharging system Or four charging and three discharges, three charging and two discharges and other multiple charging and discharging curing systems are reformed into one charging curing system. The charging method of the present invention divides the curing charging into two stages and completes it at one time. The characteristics of each stage are:

[0023] In the first stage, the new battery in the biochemical state is charged in the forward charging mode until the battery is charged to 70% of the rated capacity;

[0024] In the second stage, the battery is continuously charged to the rated capacity with a combination ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com