A kind of preparation method of aqueous phase quantum dot

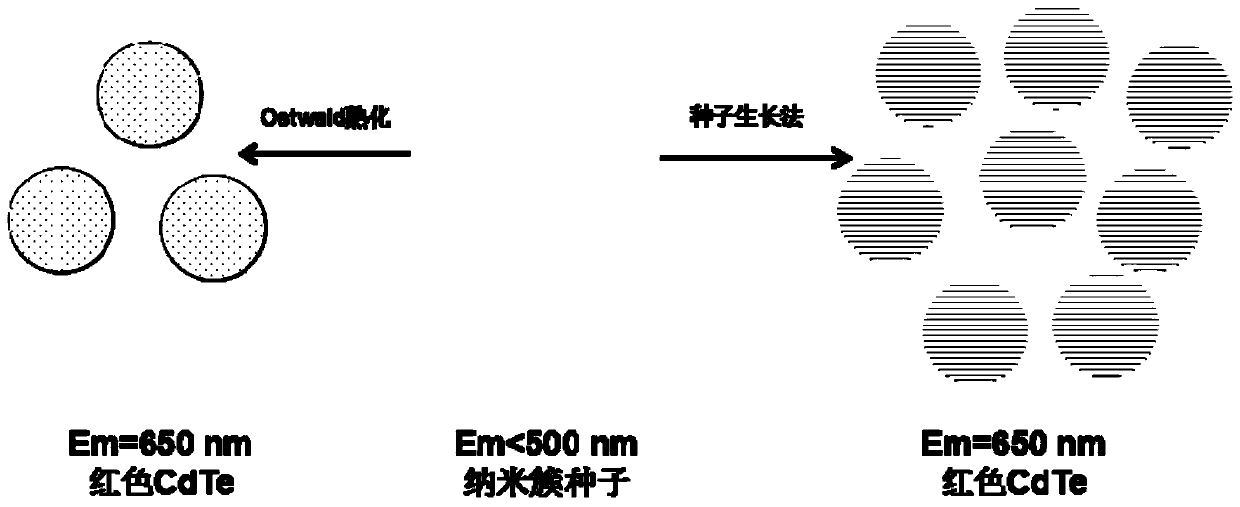

A technology of quantum dots and water phase, which is applied in the field of preparation of water phase quantum dots, can solve the problems of low utilization rate of parent raw materials, high energy consumption, and long preparation time, so as to improve the utilization rate of raw materials, reduce the aging process, and improve the quality of quantum dots. Yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

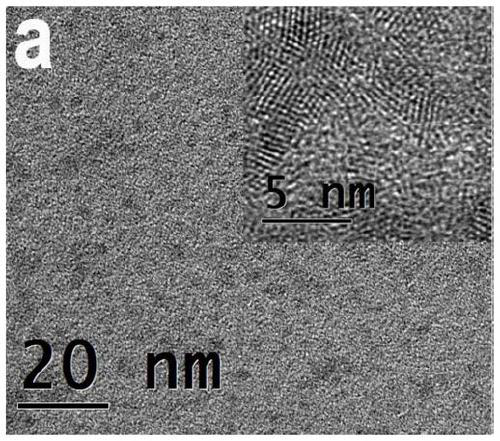

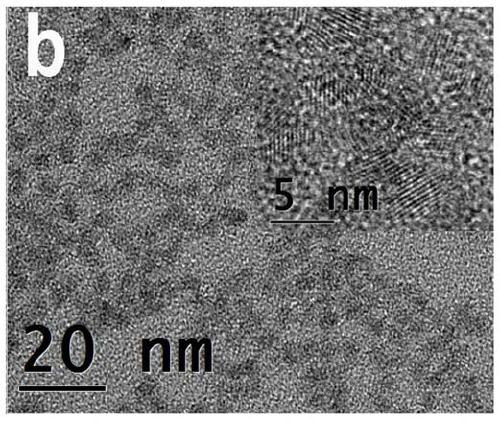

[0033] This embodiment provides a method for preparing aqueous phase quantum dots, which specifically includes the following steps:

[0034] (1) Preparation of nanocluster intermediates in aqueous phase system:

[0035] Take the Cd parent (CdCl 2 2.5H 2 O) and ligand (mercaptopropionic acid, MPA) dissolved in water, CdCl 2 2.5H 2 The molar ratio of O to mercaptopropionic acid is 1:0.5-1:5, preferably, CdCl 2 2.5H 2The molar ratio of O to mercaptopropionic acid is 1:1.6, and the resulting quantum dots have better luminescence properties. Adjust the pH of the solution to 7-14, preferably 8.5. When the pH is less than 8, the solution is turbid and the quantum dots react unevenly. The resulting particle size distribution is poor; with the increase of pH, the growth rate of quantum dots is greatly increased, which reduces the controllability, so the optimal pH of the solution is 8.5. Stir in an ice bath, quickly inject the freshly prepared Te matrix (NaHTe) aqueous solution, ...

Embodiment 2

[0063] This embodiment provides a method for preparing aqueous phase quantum dots, which specifically includes the following steps:

[0064] (1) Preparation of nanocluster intermediates in aqueous phase system:

[0065] Take the Cd parent (CdCl 2 2.5H 2 O) and ligand (mercaptopropionic acid, MPA) dissolved in water, CdCl 2 2.5H 2 The molar ratio of O to mercaptopropionic acid is 1:0.5-1:5, preferably, CdCl 2 2.5H 2 The molar ratio of O to mercaptopropionic acid is 1:1.6, and the resulting quantum dots have better luminescence properties. Adjust the pH of the solution to 7-14, preferably 8.5. When the pH is less than 8, the solution is turbid and the quantum dots react unevenly. The resulting particle size distribution is poor; with the increase of pH, the growth rate of quantum dots is greatly increased, which reduces the controllability, so the optimal pH of the solution is 8.5. Stir in an ice bath, quickly inject the freshly prepared Se matrix (NaHSe) aqueous solution,...

Embodiment 3

[0069] This embodiment provides a method for preparing aqueous phase quantum dots, which specifically includes the following steps:

[0070] (1) Preparation of nanocluster intermediates in aqueous phase system:

[0071] Take the Cd parent (CdCl 2 2.5H 2 O) and ligand (mercaptopropionic acid, MPA) dissolved in water, CdCl 2 2.5H 2 The molar ratio of O to mercaptopropionic acid is 1:0.5-1:5, preferably, CdCl 2 2.5H 2 The molar ratio of O to mercaptopropionic acid is 1:1.6, and the resulting quantum dots have better luminescence properties. Adjust the pH of the solution to 7-14, preferably 8.5. When the pH is less than 8, the solution is turbid and the quantum dots react unevenly. The resulting particle size distribution is poor; with the increase of pH, the growth rate of quantum dots is greatly increased, which reduces the controllability, so the optimal pH of the solution is 8.5. Stir in an ice bath, quickly inject the freshly prepared Te matrix (NaHTe) aqueous solution,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com