Bimetallic compound Cu/Ag plate making process

A composite plate and bimetal technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of large composite deformation, composite surface pretreatment, uneven microstructure, and difficult process implementation, so as to reduce material costs. , The equipment power and compound temperature are low, and the process parameter control is simple and convenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

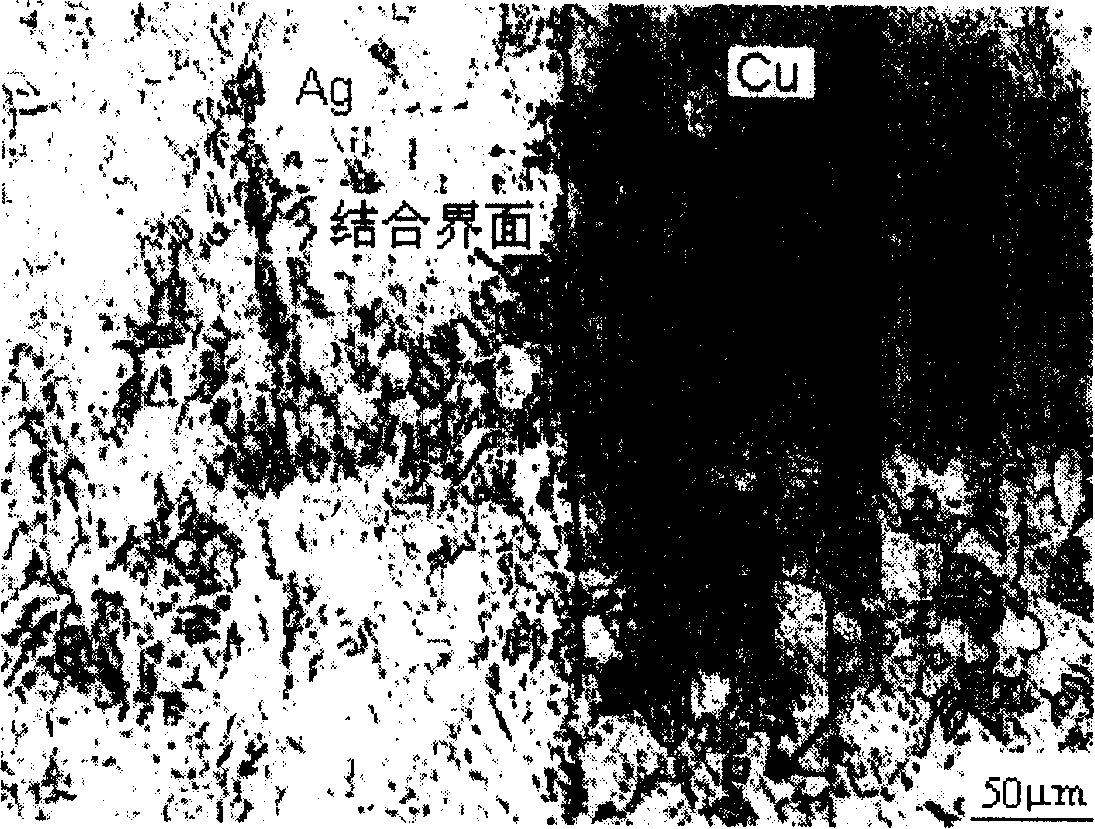

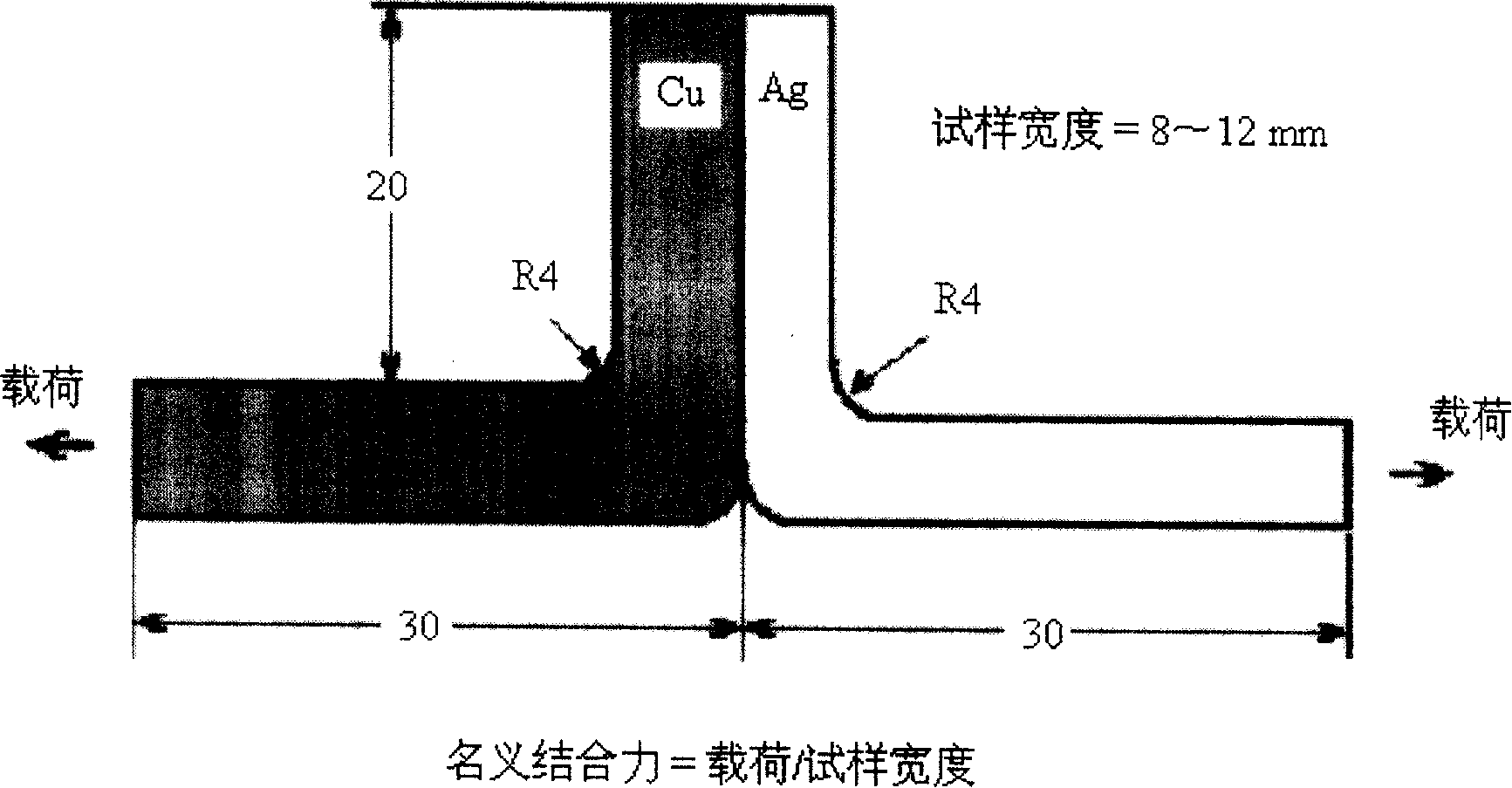

[0033] The hard industrial pure Ag strip with a thickness of 1.0mm and the hard industrial pure Cu strip with a thickness of 2.0mm are cut and degreased, and the hardness is adjusted and annealed in a protective atmosphere furnace. The Ag strip is annealed at 250°C for 0.5 h, Cu strips were annealed at 300 °C for 1 h. After annealing, the pre-stretching strain of the strip is 1% to 2% and flattened.

[0034]The surface of the substrate is cleaned by mechanical grinding, so that the surface roughness is Ra12.5±3μm.

[0035] Clean up the wear debris on the composite surface, and closely overlap the two metal strips.

[0036] Cold-rolled pre-composite, deformation 5% ( ).

[0037] 3-pass rolling compound at room temperature, with a total deformation of 70%.

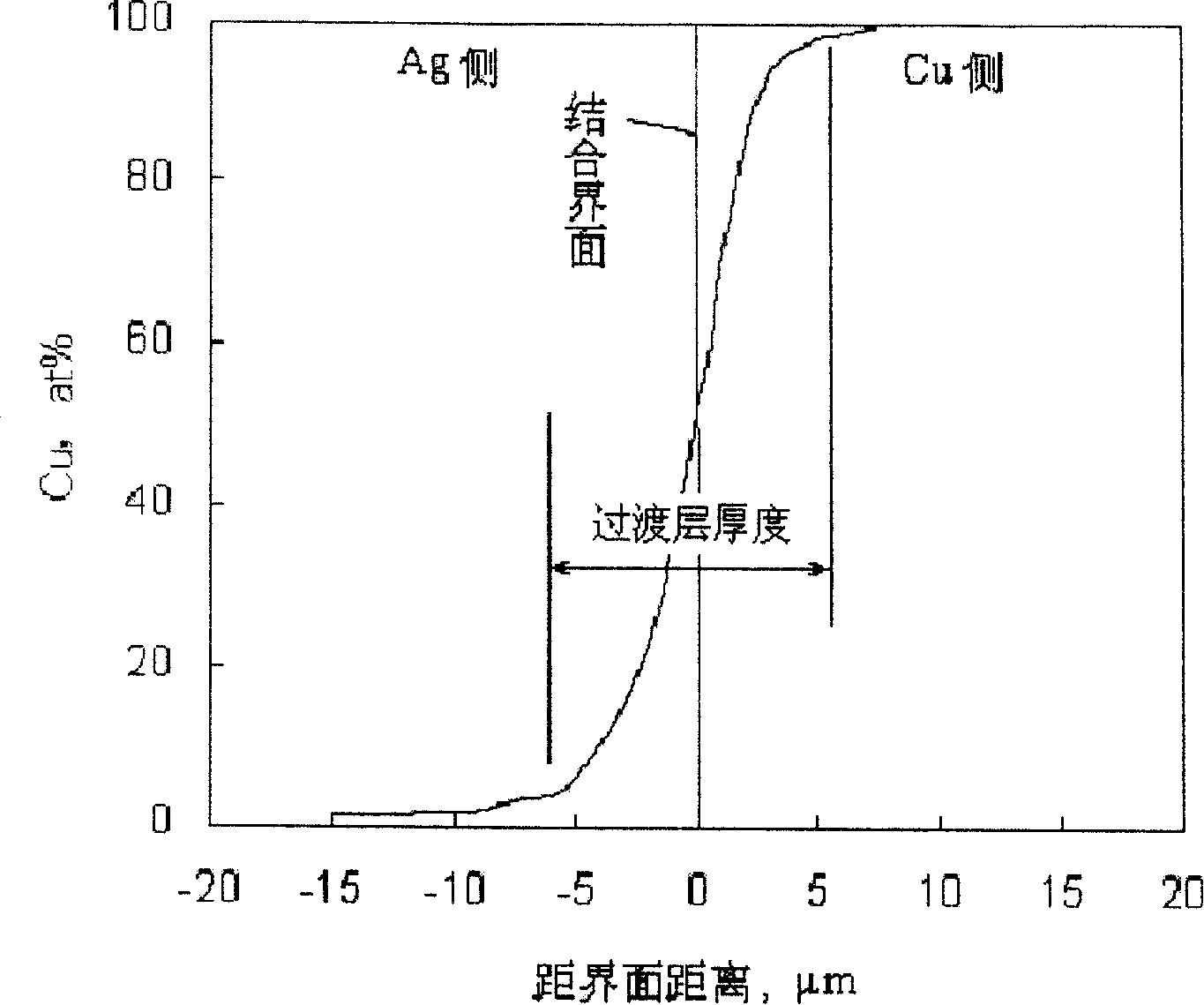

[0038] Diffusion annealing is carried out in a vacuum furnace with a gas pressure lower than 0.1Pa for the bimetallic plate after rolling and compounding. The annealing temperature is 400°C and the annealing time is 4...

Embodiment 2

[0044] The hard state industrial pure Ag strip with a thickness of 2.0mm and the hard industrial pure Cu strip with a thickness of 4.0mm are cut and degreased, and the hardness is adjusted and annealed in a protective atmosphere furnace. The Ag strip is annealed at 300 ° C for 0.5 h, Cu strips were annealed at 300 °C for 1 h. After annealing, the pre-stretching strain of the strip is 1% to 2% and flattened.

[0045] The surface of the substrate is cleaned by mechanical grinding, so that the surface roughness is Ra50±5μm.

[0046] Clean up the wear debris on the composite surface, and closely overlap the two metal strips.

[0047] Cold-rolled deformation pre-composite, the degree of deformation is 5%.

[0048] 200°C rolling composite, 5 passes, total deformation 80%.

[0049] Diffusion annealing is carried out in a vacuum furnace with a gas pressure lower than 0.1Pa for the bimetallic plate after rolling and compounding. The annealing temperature is 450°C and the annealing t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com