A short-section welder with variable cross-section double-needle riveting enhanced friction stir welding

A friction stir, variable cross-section technology, used in welding equipment, manufacturing tools, non-electric welding equipment, etc., can solve problems such as joint embrittlement, hook defects, welding tool tip wear, etc., to increase stability, promote atomic diffusion, enhance The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

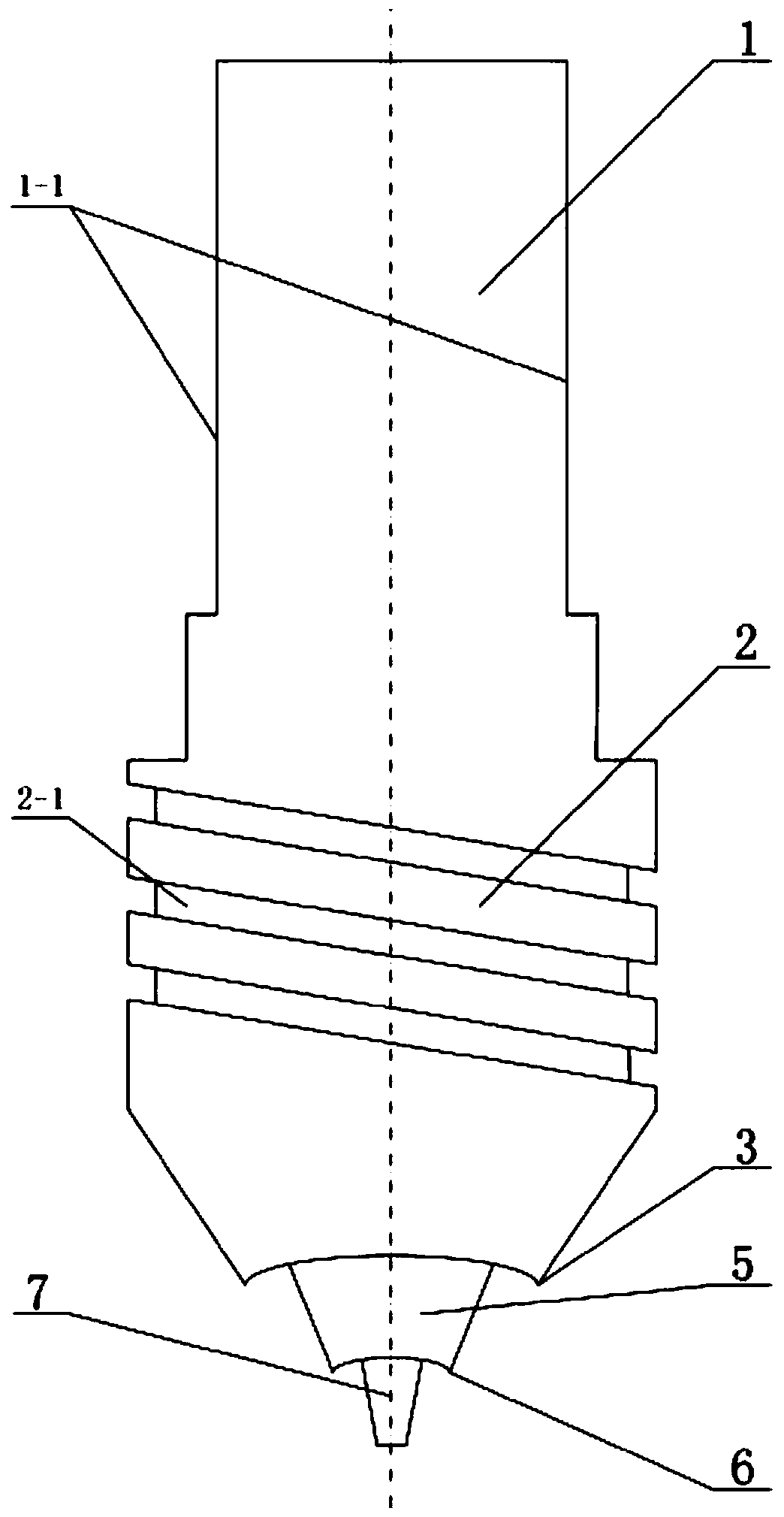

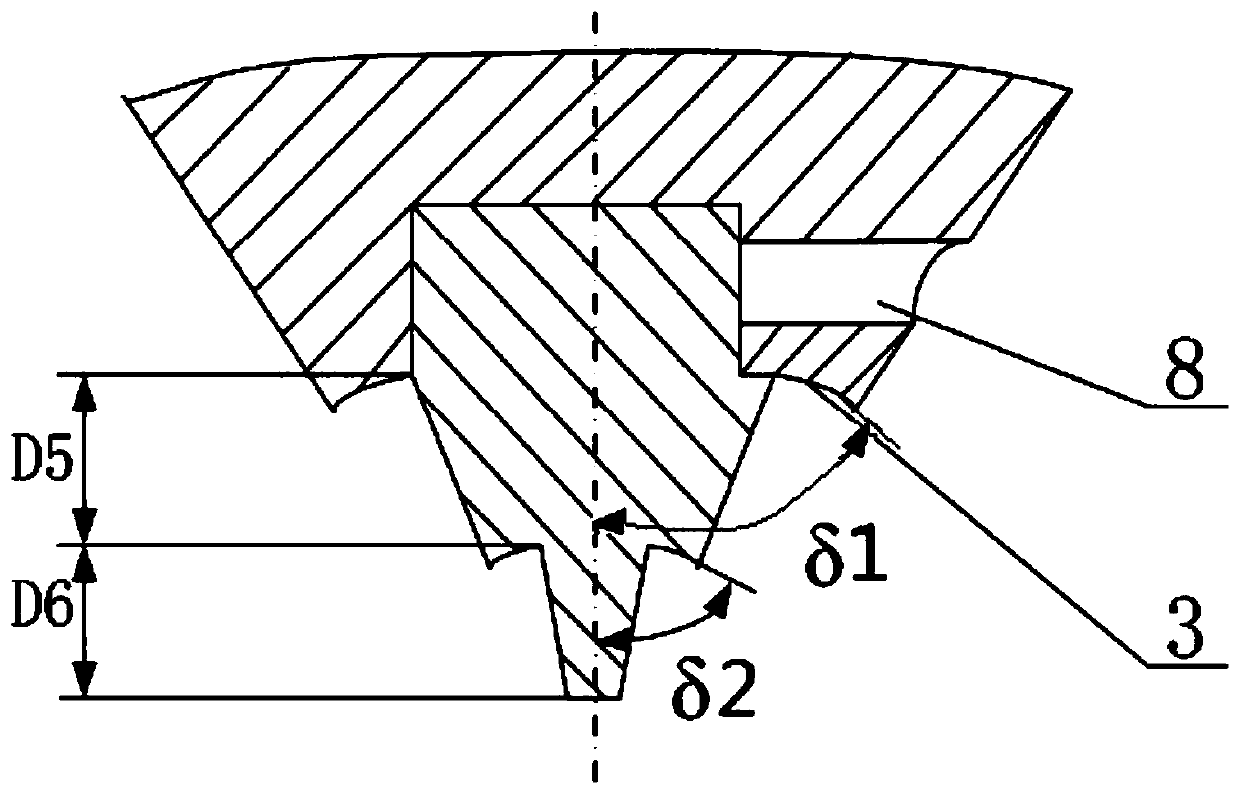

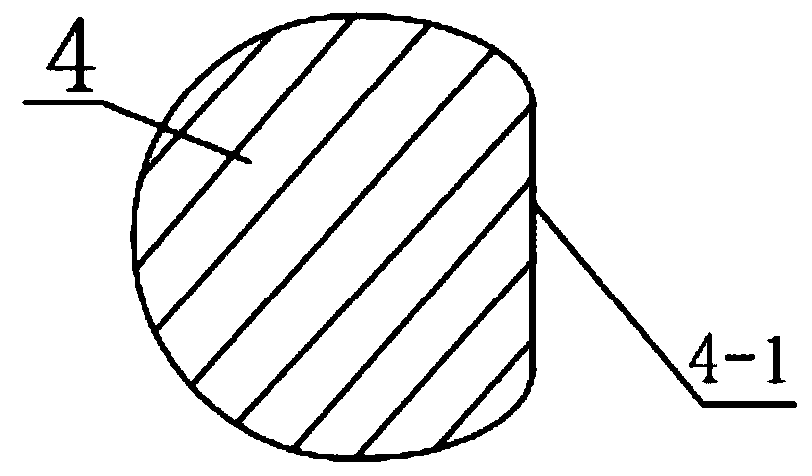

[0029] Combine below Figure 1-5 Describe this embodiment, a variable cross-section double-needle riveting strengthened friction stir short-section welding tool, including a clamping body and a stirring pin, the stirring pin is fixedly connected to the lower end of the clamping body, and the stirring pin includes a connecting key 4 , a large stirring needle 5, a narrow concave shoulder 6 and a small stirring needle 7, the connecting key 4 is a single-sided key or a double-sided key, the lower end of the large stirring needle 5 is provided with a narrow concave shoulder 6, and the connecting The key 4, the large stirring needle 5, the narrow concave shoulder 6 and the small stirring needle 7 are fixedly connected sequentially from top to bottom, and the large stirring needle 5 and the small stirring needle 7 are all conical structures with threads arranged in the circumferential direction; At the beginning of welding, when the welding tool is rotated and pressed down, the small...

specific Embodiment approach 2

[0031] Combine below Figure 1-5 Describe this embodiment, this embodiment will further explain Embodiment 1, the clamping body includes a clamping part 1, a heat dissipation part 2 and a wide concave shoulder 3, the clamping part 1, a heat dissipation part 2 and a wide concave shoulder Shaft shoulder 3 is fixedly connected sequentially from top to bottom, the clamping part 1 is provided with a clamping surface 1-1, the diameter of the clamping part 1 is smaller than the diameter of the heat dissipation part 2, and the heat dissipation part 2 is provided with The heat dissipation groove 2-1, the heat dissipation groove 2-1 is a spiral groove with 3 to 5 turns, the connecting key 4 is matched and connected in the keyway provided at the lower end of the wide concave shoulder 3, and the wide concave shoulder 3 A fastening threaded hole 8 is provided on the top, and the fastening threaded hole 8 communicates with the keyway at the lower end of the wide concave shoulder 3. The fast...

specific Embodiment approach 3

[0033] Combine below Figure 1-5 Illustrate this embodiment, this embodiment will further illustrate embodiment two, the material of the clamping body is one or more of high-speed steel, tool steel, tungsten-cobalt alloy steel and nickel-based alloy steel, the stirring The needle is selected from the same material as the steel to be welded.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com