Organic solvent coated nano boron particles as well as preparation method and application thereof

An organic solvent, nano-boron technology, applied in the method of granulating raw materials, coating particles, nano-technology, etc., can solve problems such as application limitations of boron-containing propellants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

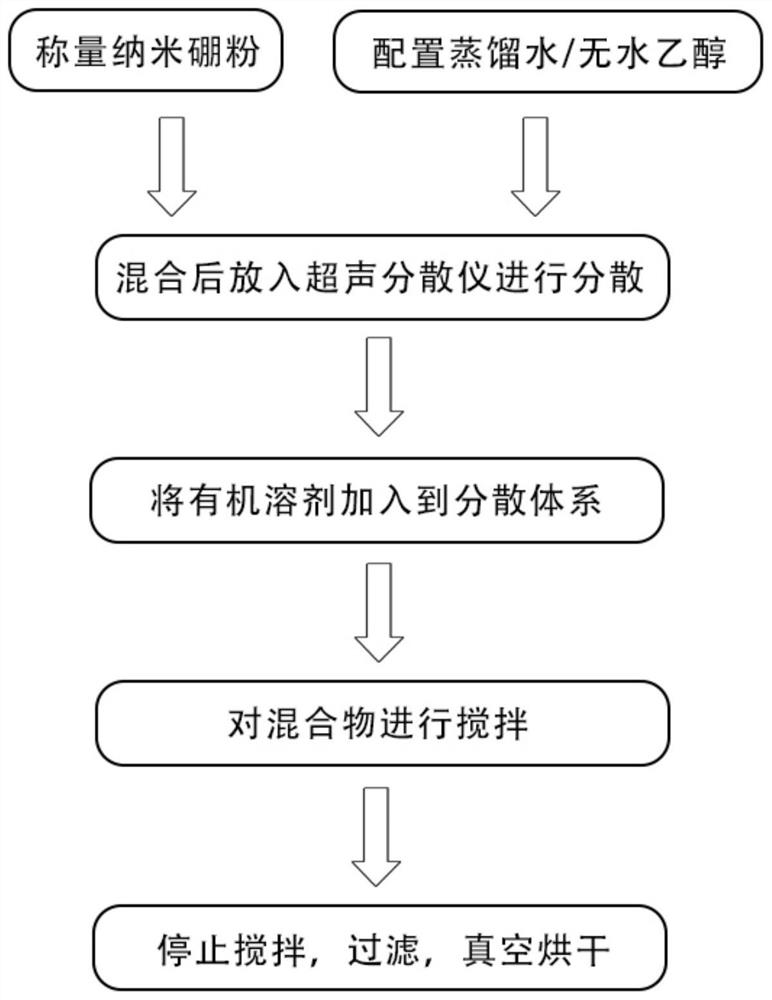

[0026] The present invention also provides a method for preparing organic solvent-coated nano-boron particles described in the above technical solution, comprising the following steps:

[0027] Dispersing nano-boron powder in an alcohol-water mixed solvent to obtain a boron dispersion;

[0028] mixing the boron dispersion with an organic solvent to obtain organic solvent-coated boron nanoparticles;

[0029] Described organic solvent is ethylenediamine or gasoline.

[0030] Unless otherwise specified, the present invention has no special requirements on the sources of the raw materials used for the preparation, and commercially available products well known to those skilled in the art can be used.

[0031] The invention disperses the nanometer boron powder in the mixed solvent of alcohol and water to obtain the boron dispersion liquid.

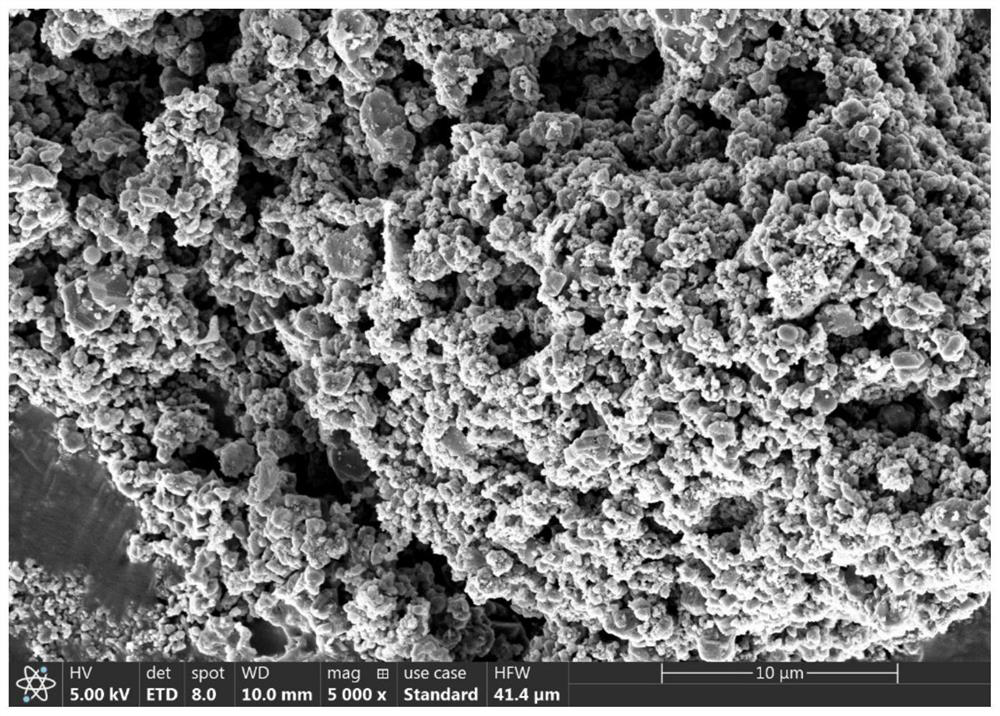

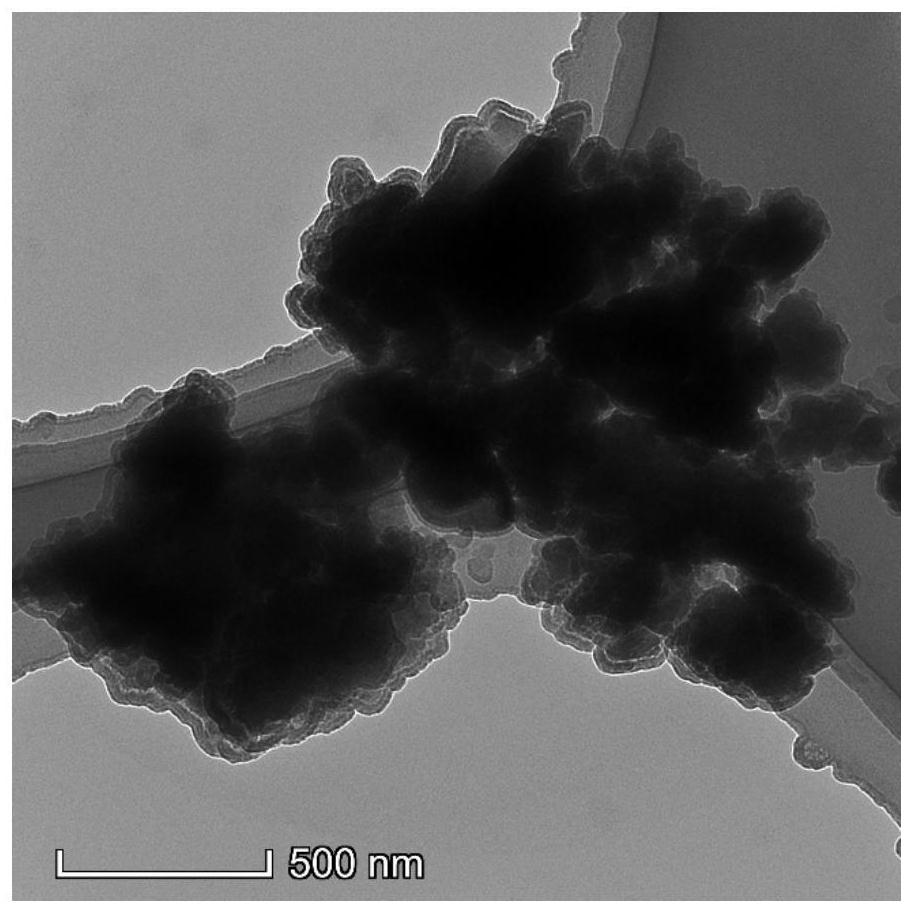

[0032] In the present invention, the average particle size of the nano boron powder is preferably 200nm.

[0033] In the present invention,...

Embodiment 1

[0049] Weigh 0.2g of nano-boron powder (average particle size is 200nm) and add it into 100mL (92.80g) alcohol-water mixed solvent (the volume ratio of absolute ethanol and water is 1:1), and disperse at 25°C with an ultrasonic disperser 40min (dispersing power is 500W), obtain dispersion liquid;

[0050]Add 5 mL of ethylenediamine (4.50 g) dropwise to 25 mL of the above dispersion, stir magnetically at 25°C for 1 h at a stirring rate of 300 r / min, let stand for 50 min, and filter the resulting oil phase under reduced pressure. The obtained solid material was dried for 30 minutes under vacuum conditions of MPa and 70° C. to obtain organic solvent-coated boron nanoparticles.

Embodiment 2

[0052] The difference from Example 1 is that the consumption of ethylenediamine is 10mL, and the rest of the contents are consistent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com