Brake shoe cooling system

A technology for cooling systems and brake pads, applied in the direction of brakes, cooling brakes, vehicle components, etc., can solve problems such as thermal recession of metal brake pads, and achieve the effect of solving thermal recession, high measurement accuracy, and avoiding brake slippage or failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

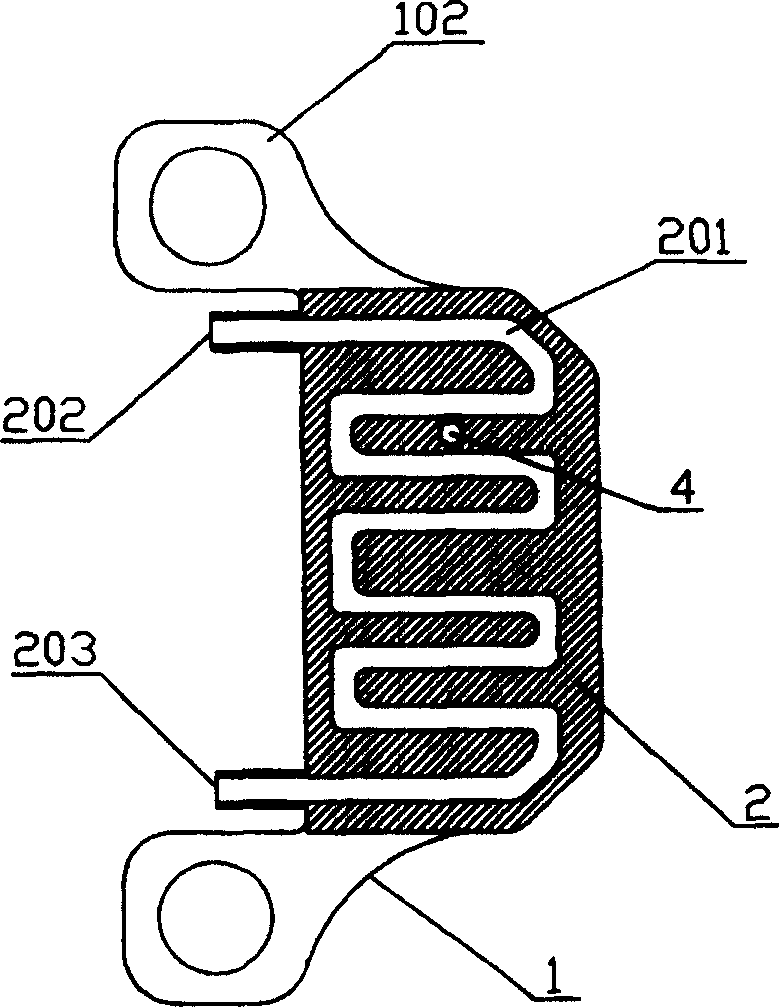

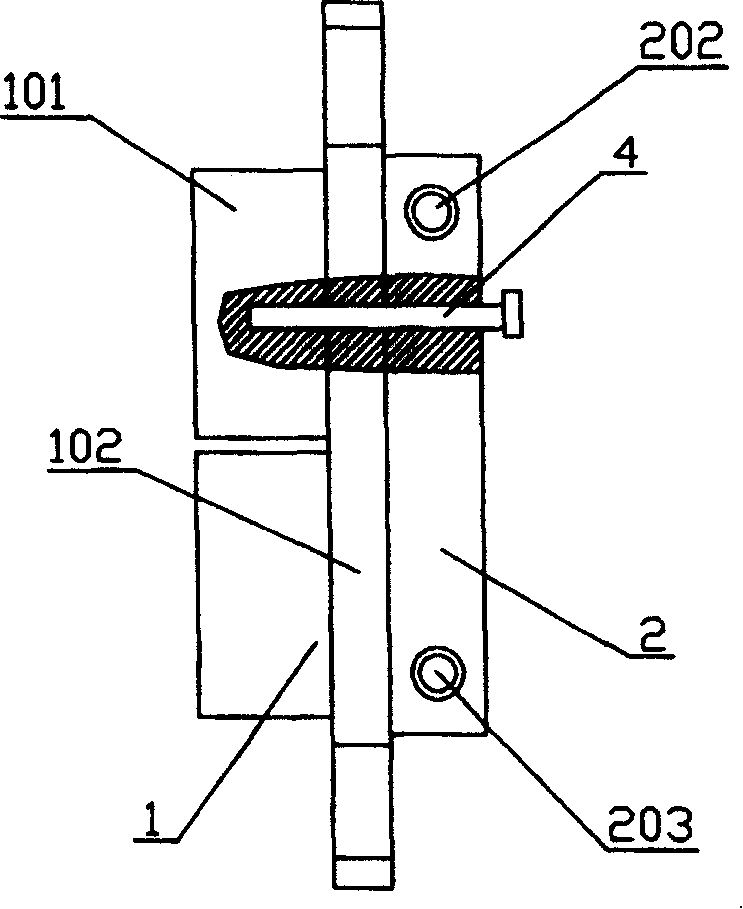

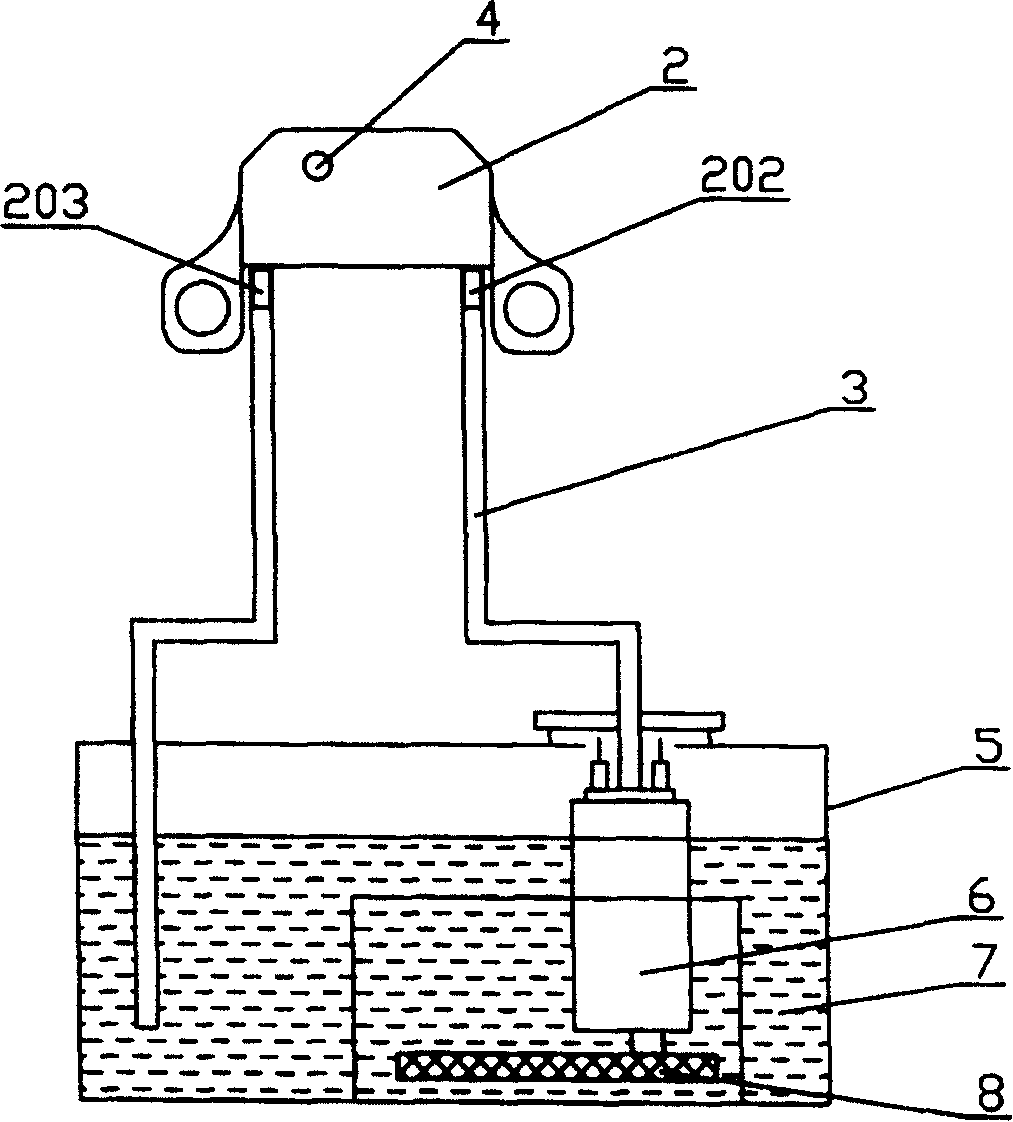

[0032] Embodiment of brake pad cooling system of the present invention, as figure 1 , 2 As shown, it includes a brake pad 1, and it also includes a water cooling system, the water cooling system includes a heat dissipation pipe, and the heat dissipation pipe is fixed on the brake pad 1. The brake pad 1 includes a friction pad 101 and a steel back 102 , the friction pad 101 is fixed on one surface of the steel back 102 , and the heat dissipation pipe is fixed on the other surface of the steel back 102 .

[0033] The radiating pipe is a steel sheet 2 with a water tank 201, and the steel sheet 2 is provided with a water inlet 202 and a water outlet 203 communicating with the water tank 201; It is pre-punched on the steel sheet 2. This surface of the steel sheet 2 is sealed and pasted on the steel back 102 by a high-temperature-resistant adhesive to avoid overflow of water in the steel sheet water tank. The steel sheet 2 is chrome-plated to prevent the water tank from being cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com