Heat pipe applied to brake pad and production method thereof

A technology for brake pads and heat pipes, which is applied in the field of heat pipes that can dissipate heat and generate thrust and their preparation fields, achieves the effects of solving thermal decay, fast heat conduction, and rapid response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

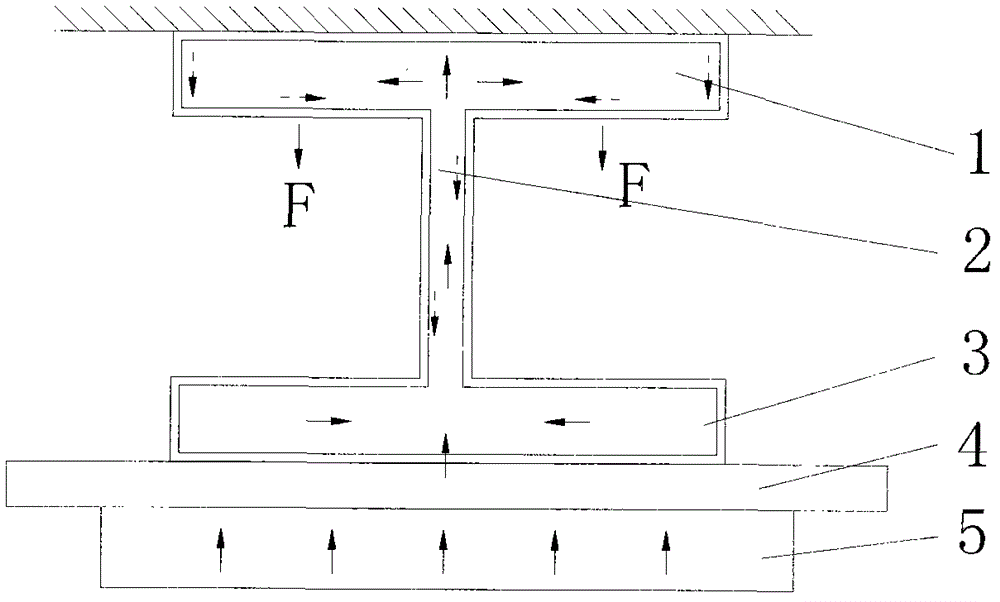

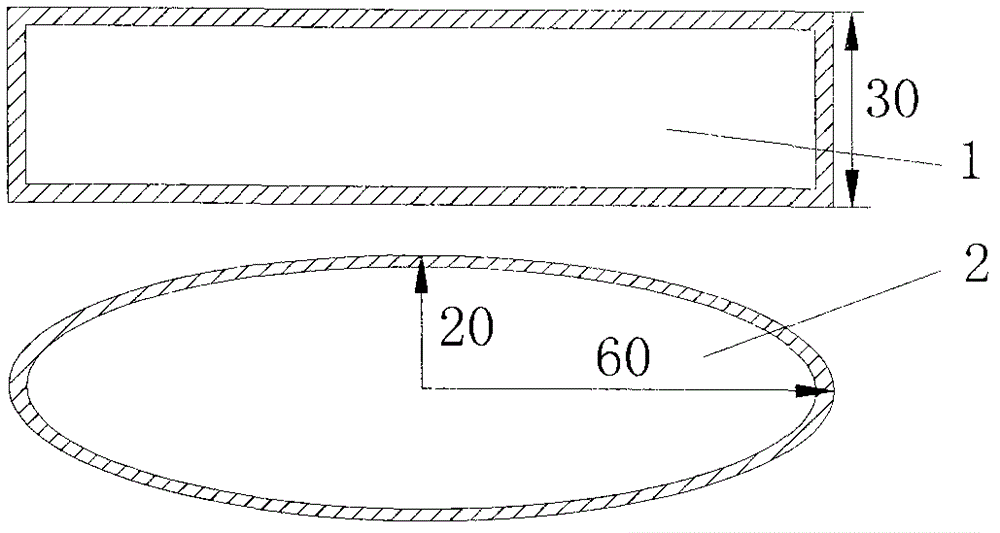

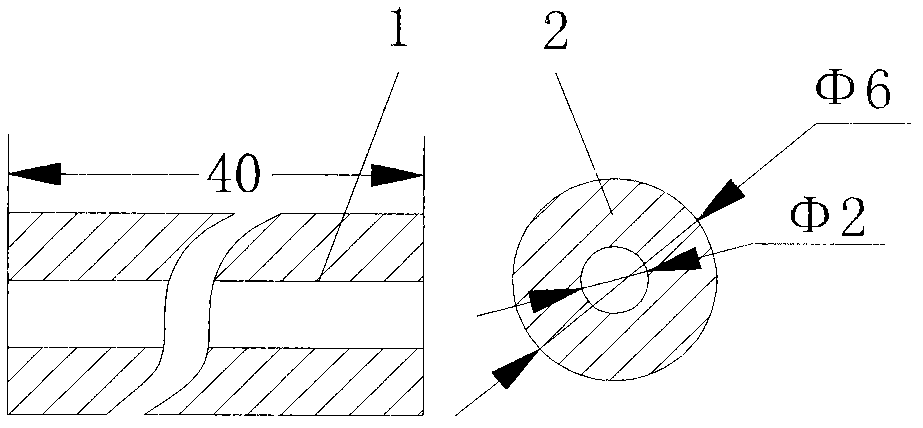

[0040] The heat pipe used for automobile brake pads provided by the present invention can quickly dissipate heat and cool down, and at the same time generate directional thrust. The evaporation end is fixed on the steel back side of the brake pad. The shape of the heat pipe is I-shaped, and copper is used as the shell material. , the evaporating end and the condensing end are elliptical cylindrical box-shaped cavities, the upper surface of the evaporating end and the upper surface of the condensing end are connected by a circular connecting pipe with a diameter of 15mm, and a liquid-absorbing core is arranged on the inner side of the connecting pipe , is an axial groove composed of multiple Ω shapes, the groove depth is 0.6mm, and the aspect ratio is 1.5:1. The evaporating end has a hole for the insertion and tight welding of the perfusion tube. The perfusion tube is sealed by cold welding and then welding. The inner diameter is 1 / 16 inch and the outer diameter is 1 / 4 inch.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com