Double-rotor motor for pure electric vehicle with retarding and differential functions and working method

A pure electric vehicle and dual-rotor motor technology, applied in electric vehicles, motors, electric components, etc., to achieve the effect of restraining braking deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

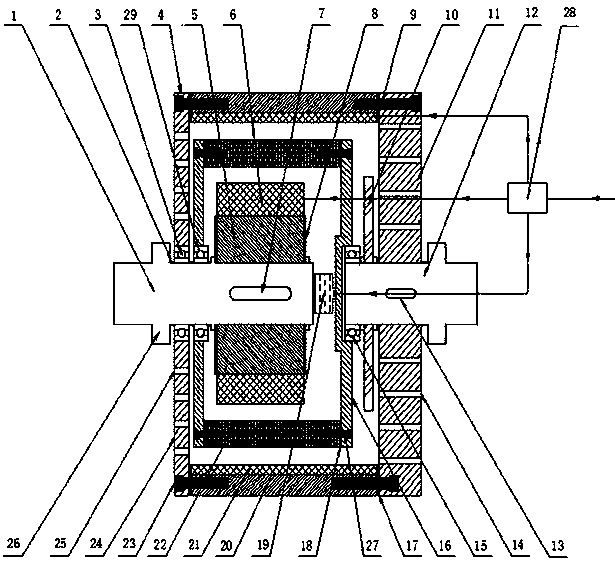

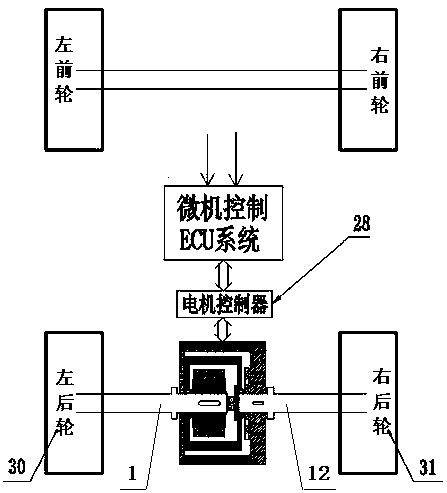

[0021] see figure 1 , the double-rotor motor for pure electric vehicles with retarding and differential functions in the present invention includes a left casing 4 and a right casing 11, and the outermost layer of the left casing 4 and the right casing 11 is an outer casing 24. The outer casing 24 is made of magnetic shielding material.

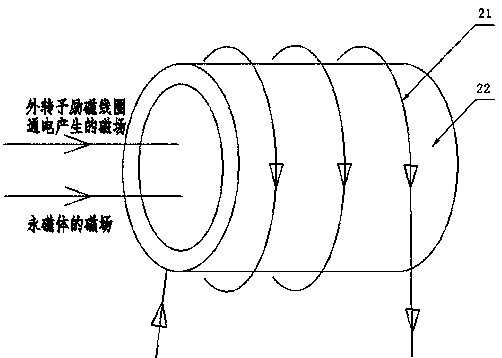

[0022] An inner rotor 5 , an inner rotor field coil 6 , an outer rotor 20 , an outer rotor field coil 21 , a permanent magnet 22 and a permanent magnet bracket 16 are arranged between the left side case 4 and the right side case 11 . The inner rotor 5 , the permanent magnet 22 and the outer rotor 20 are coaxially nested from inside to outside, and the left and right ends of the permanent magnet 22 are fixed on the permanent magnet bracket 16 by third screws 27 .

[0023] An outer rotor excitation coil 21 is wound inside the outer rotor 20 . The left end of the outer rotor 20 is fixedly connected to the left housing 4 through the second scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com