Socket spot-welding collar pipe fitting for thin wall stainless steel pipe and copper pipe

A technology of stainless steel pipes and plug-in points, which is applied in the direction of pipes/pipe joints/fittings, passage components, mechanical equipment, etc., which can solve problems affecting the tightness of thin tubes and fittings, and achieve the effect of convenient repair and prevention of adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

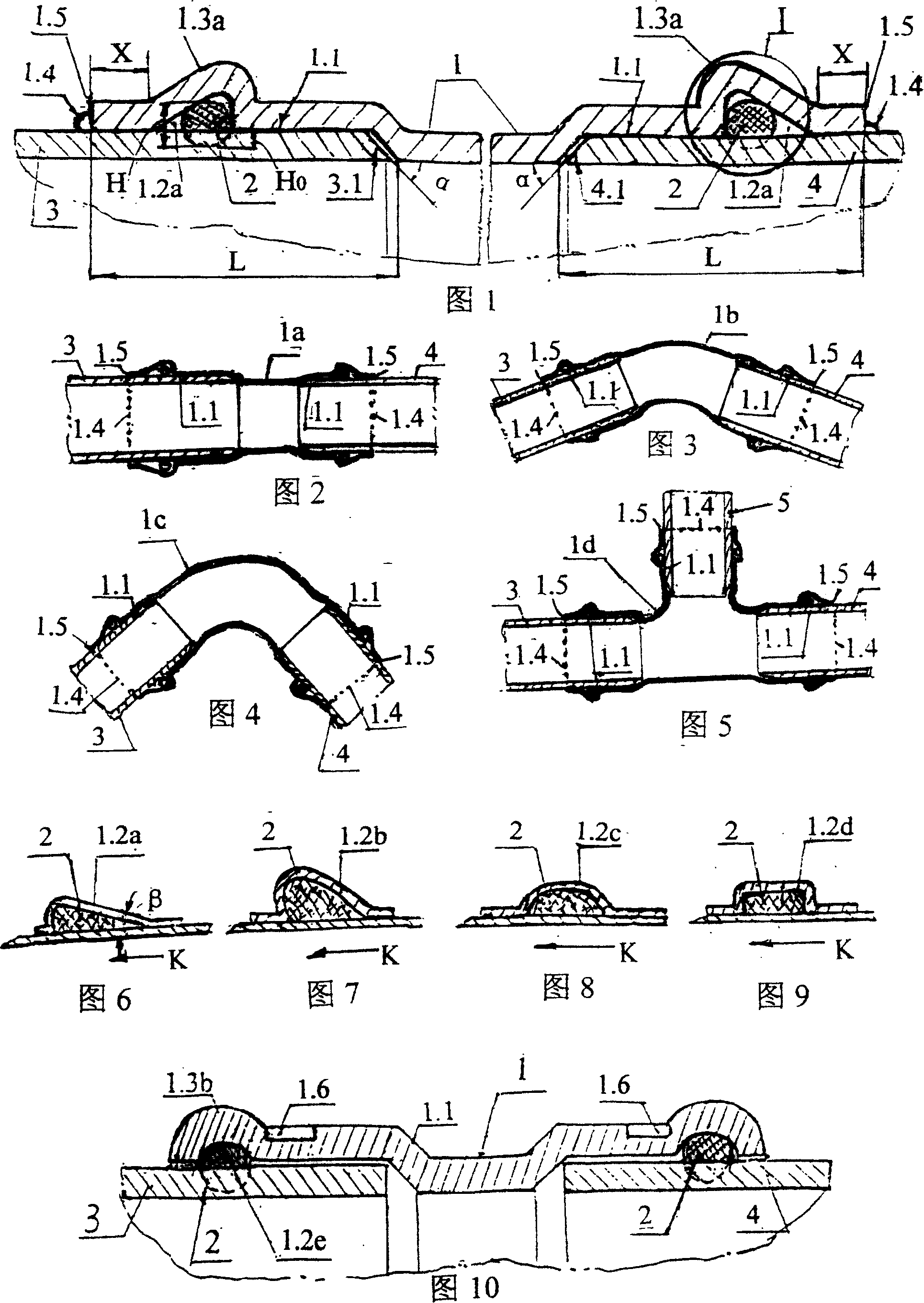

[0033] Embodiment 1: See Fig. 1, this pipe fitting is the straight head that is used for being connected two thin pipes with equal diameter.

[0034] The pipe fitting is provided with a straight connecting body 1 made of stainless steel, and the inner sides of its two ports 1.5 are a section of reaming section 1.1, and the connected two thin tubes are stainless steel pipes 3 and 4 respectively inserted into the connecting body from the two ports of the straight connecting body hole, and extend to the end of the reaming section 1.1, the overlapping section of the thin tube and the connecting body is L. In the L section, an annular groove 1.2a is opened at both ends of the connecting body hole, and an O-shaped rubber sealing ring 2 is placed in it, so that an annular convex part 1.3 is formed at the corresponding grooves at both ends of the connecting body surface a.

[0035] The two ports 1.5 of the connecting body are respectively connected and fixed with the connected thin t...

Embodiment 2

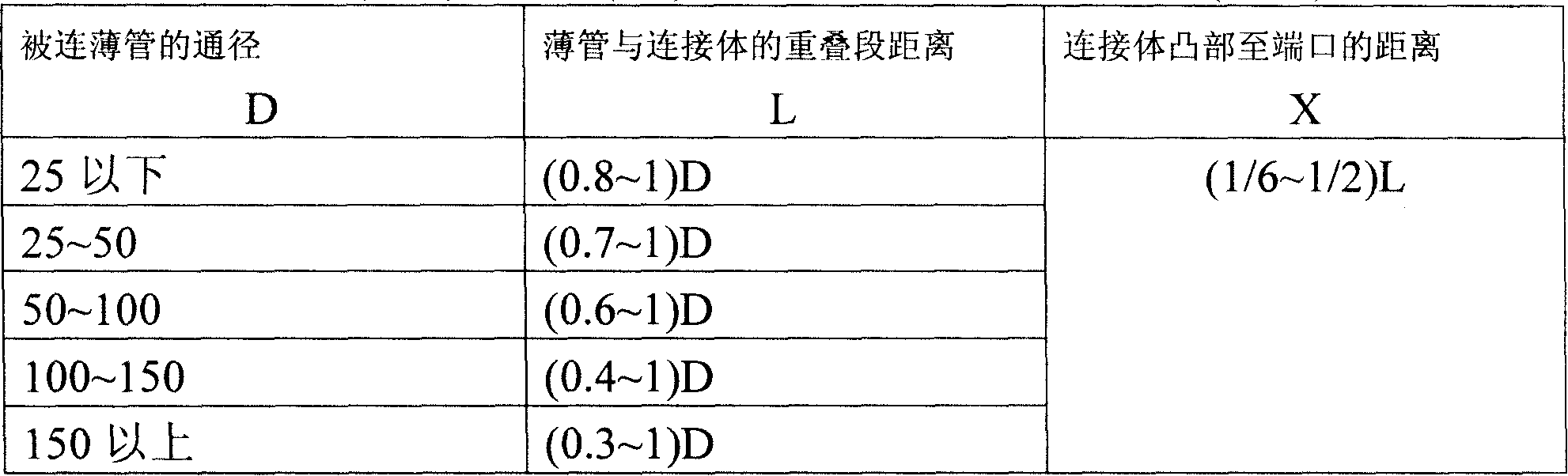

[0042] Embodiment 2: See Fig. 2, this pipe fitting is the straight head that is used for being connected two thin pipes with different diameters.

[0043] The outer diameter Φ of the connected thin tube 3 is 219mm, and the outer diameter Φ of the thin tube 4 is 159mm. The two thin tubes 3 and 4 to be connected are inserted into the two reaming sections 1.1 in tight fit from the two ports 1.5 of the straight connection body 1a with different diameters respectively. After inserting according to the installation process described in Embodiment 1, 16 flash welding spots are used to complete the 'flash welding lock', each 4 square millimeters, so that the cannula is not pulled out. The rest of the structural shapes and parameters are the same as in Example 1.

Embodiment 3

[0044] Embodiment 3: See Fig. 3, this pipe fitting is the 45 ° elbow that is used to be connected two thin pipes with equal diameter.

[0045] The two connected thin tubes 3 and 4 are inserted into the two reaming sections 1.1 with tight fit from the two ports 1.5 of the 45° elbow connection body 1b respectively. For example: the outer diameter of the thin tubes 3 and 4 is 219mm, and there are 16 flash welding spots, each of which is 4 square millimeters. The rest of the structural shapes and parameters are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com