Seat heater and its producing method

A technology of a heating device and a manufacturing method, which can be applied to seat heating/ventilation devices, special positions of vehicles, vehicle seats, etc. Low cost, sitting comfortably, the effect of reduced quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

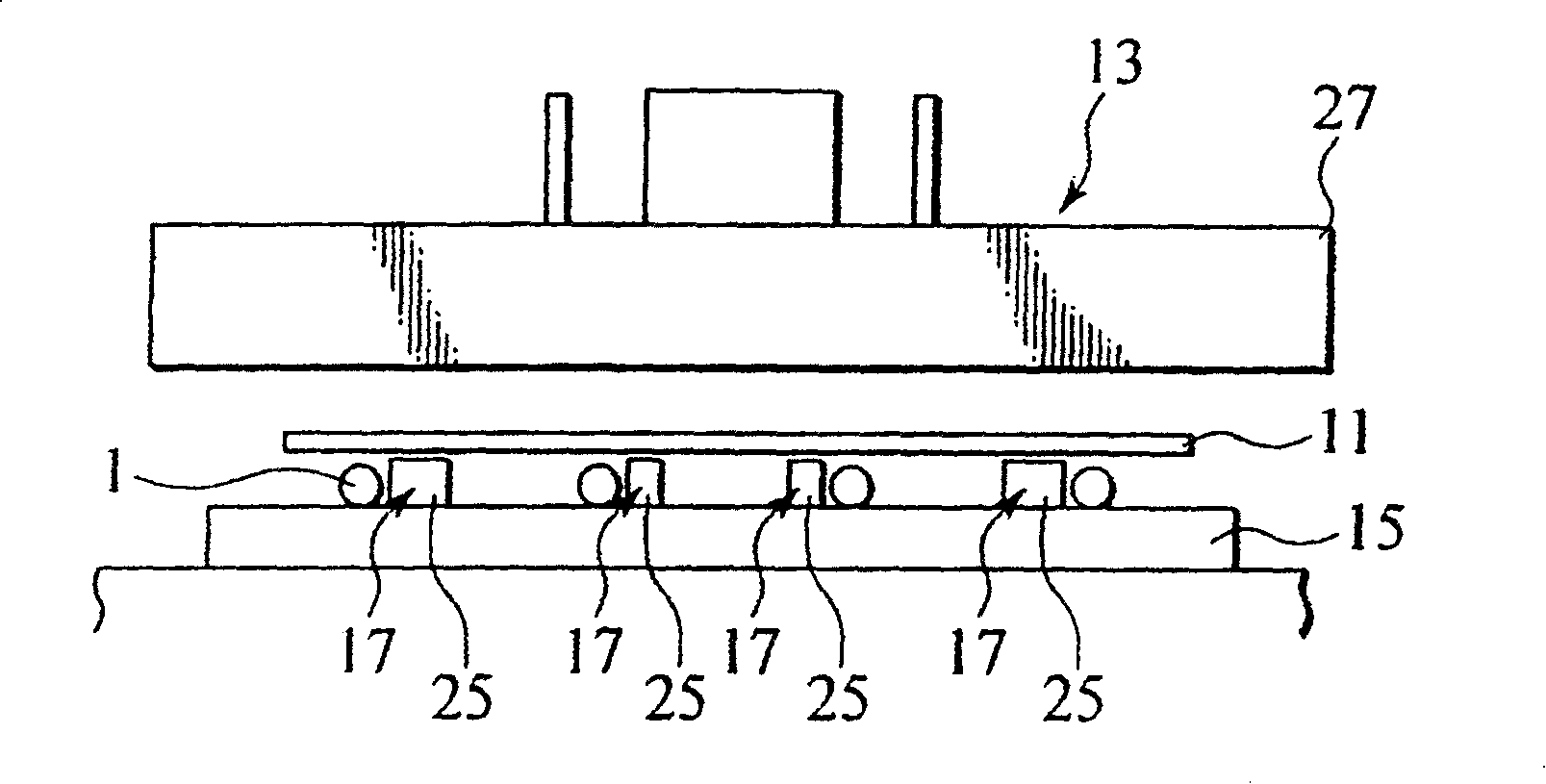

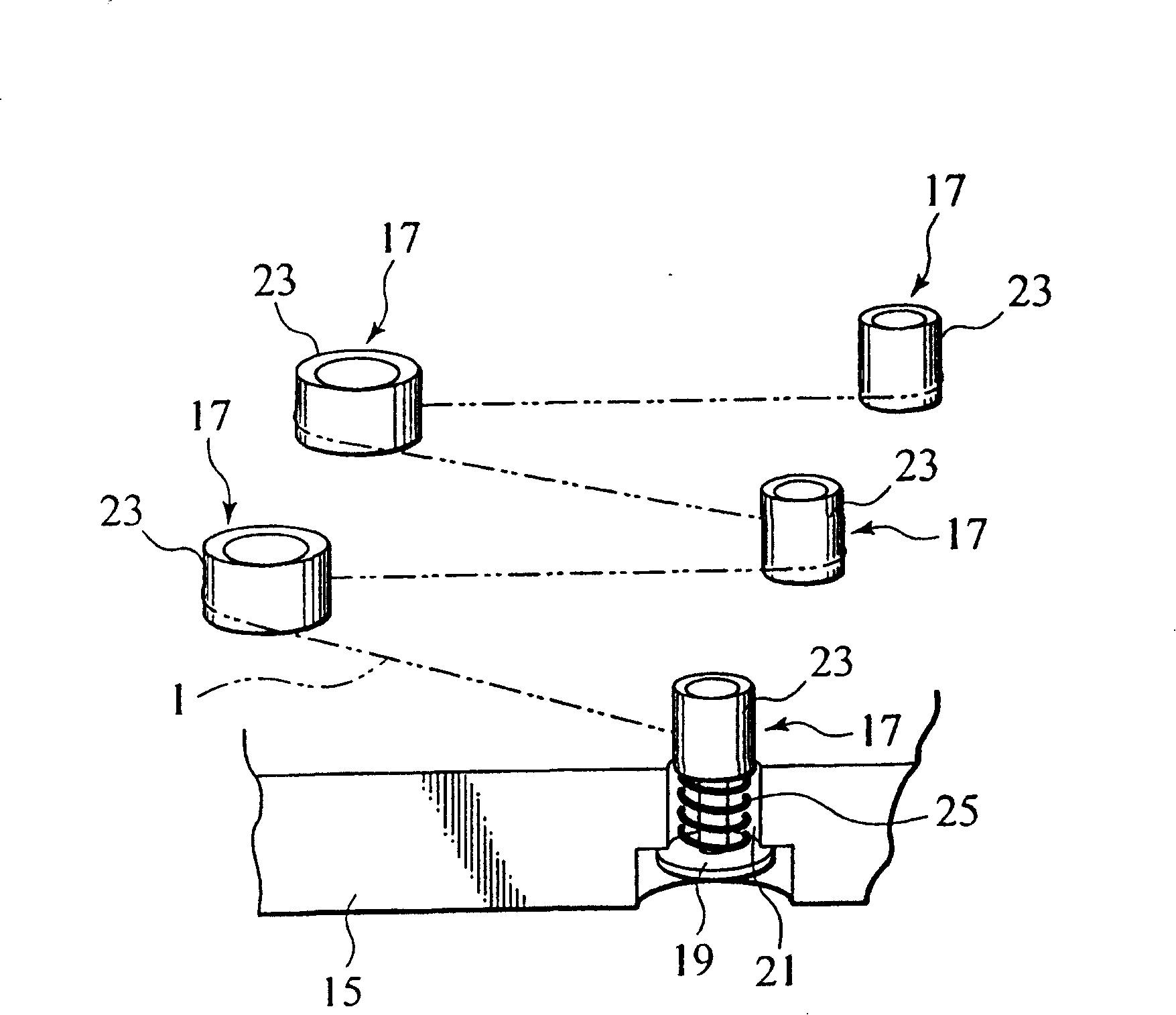

[0078] now refer to Figures 1 to 6 A first embodiment of the present invention will be described. The example described in the first embodiment assumes that the present invention is applied to a seat heating device for a vehicle.

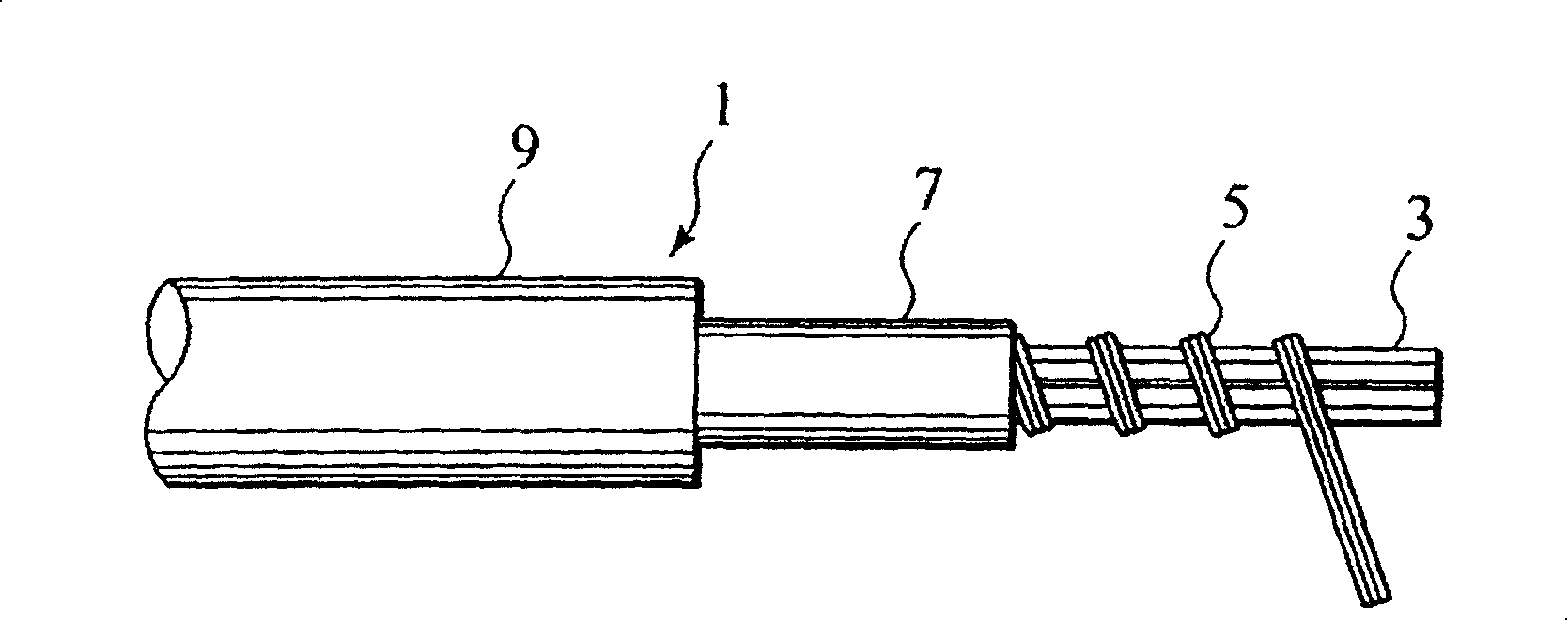

[0079] now refer to figure 1 The structure of a heating wire 1 according to the first embodiment of the present invention will be described. The heating wire 1 includes a core wire 3 of a heating element made of a bundle of aromatic polyamide, with an outer diameter of about 0.2 mm; The helical spacing is about 0.7 mm. The heating element 5 includes six parallel heating wires, each of which has an outer diameter of about 0.08 mm and is made of tin-plated copper-tin alloy (TH-SNCC-3). The outer periphery of the above-mentioned heating element 5 is covered with an extruded insulating layer 7 with a thickness of about 0.15 mm, which is made of a copolymer of tetrafluoroethylene and hexafluoropropane (FEP). In addition, the outer periphery of the...

no. 2 example

[0108] now refer to Figure 7 A second embodiment of the present invention will be described. According to the first embodiment described above as an example showing the basic structure of the heating wire, a heating element is provided in which a plurality of parallel heating wires are wound on the outer periphery of the core wire of the heating element. However, the invention is of course not limited to this first embodiment.

[0109] For example, according to the second embodiment, the present invention can also be applied to a system such as Figure 7 A so-called "high tensile strength type" heating wire 51 is shown. It will be described in detail below.

[0110] The structure of the heating wire 51 will now be described according to the second embodiment. It has a core wire 53 made of a bundle of aromatic polyamide fibers and a heating element 55 wound helically on the outer periphery of the core wire 53 of the heating element. The heating element 55 is in the form o...

no. 3 example

[0113] now refer to Figure 8 A third embodiment of the present invention will be described. Figure 8 Shown is a so-called "single wire" heater wire 61 configuration. As in the case of the first and second embodiments, the present invention can also be applied to this type of heating wire 61 .

[0114] The structure of the heating wire 61 will now be described according to the third embodiment. It has a heating element core wire 63 made of glass fiber or polyester fiber and a heating element 65 helically wound on the outer periphery of the heating element core wire 63 . The heating body 65 includes a heating wire.

[0115] The heating element 65 may also include a plurality of heating wires.

[0116] The outer periphery of the heat generating body 65 is covered with an extruded fusion layer 67 made of polyester-based resin such as nylon-11 or nylon-12. In addition, a nickel wire 69 is helically wound on the outer periphery of the fusion layer 67 to be used as a heat dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com