Method for placing ground wire in producing cable and device thereof

A grounding wire and cable technology, used in insulated cables, cable/conductor manufacturing, cables, etc., can solve the problems of small bumps, cable sheath hook-shaped protrusions, grounding wire breakage, etc., to eliminate hook-shaped protrusions or grounding Effect of wire breakage, enhanced flexibility, and improved electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

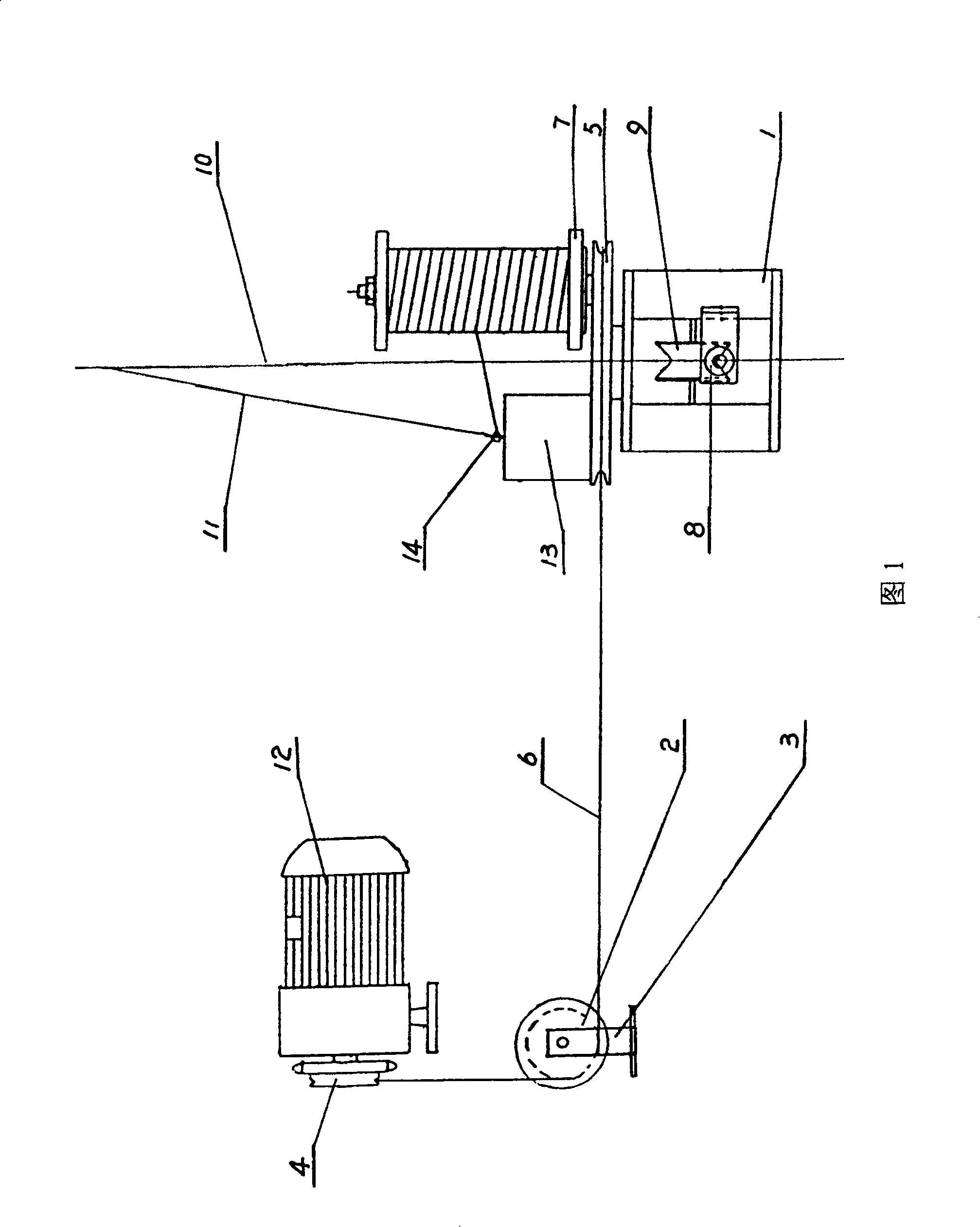

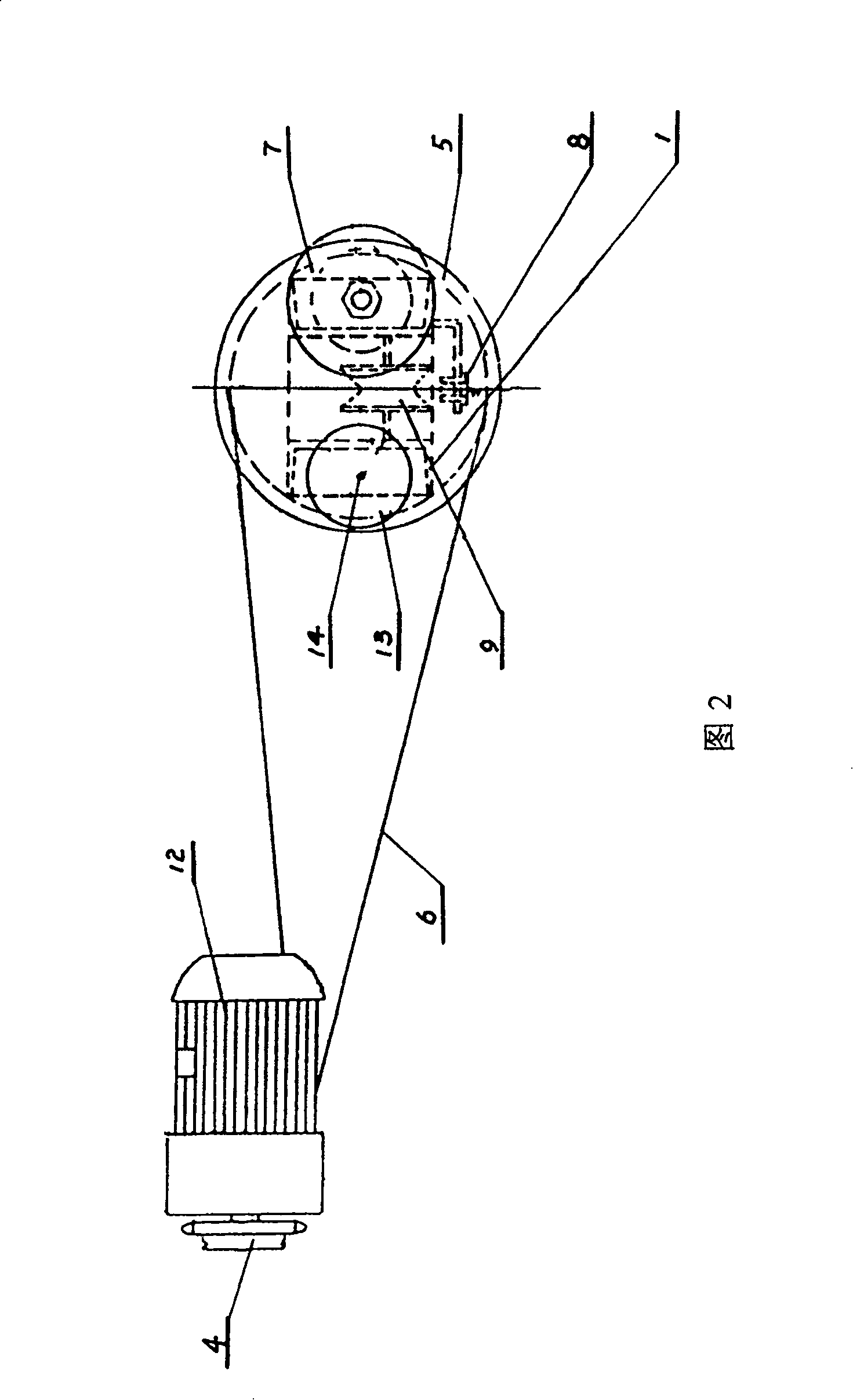

[0012] Referring to Fig. 1, 2, the present invention comprises support 1, steering wheel 2, steering wheel bracket 3, driving and driven wheels 4,5, belt 6, and driving wheel 4 connects the take-up motor 12 in the original equipment, and steering wheel 2 is provided with On the steering wheel bracket 3, the driven wheel 5 is located on the support 1, and the belt 6 connects the driving wheel 4, the steering wheel 2 and the driven wheel 5; Wire passing die 8 and core wire guide wheel 9 are arranged under the wheel 5; in the cable production process, when the shielding layer needs to be braided or wrapped, the braiding machine is started, and the wire take-up motor 12 runs simultaneously when the braiding disc is running. The belt 6 in the present invention drives the driving and passive wheels 4, 5 to rotate, and the grounding wire reel 7 rotates at the same time, so that the grounding wire 11 on it is wound around the wire that enters through the wire passing mold 8 and the cor...

Embodiment 2

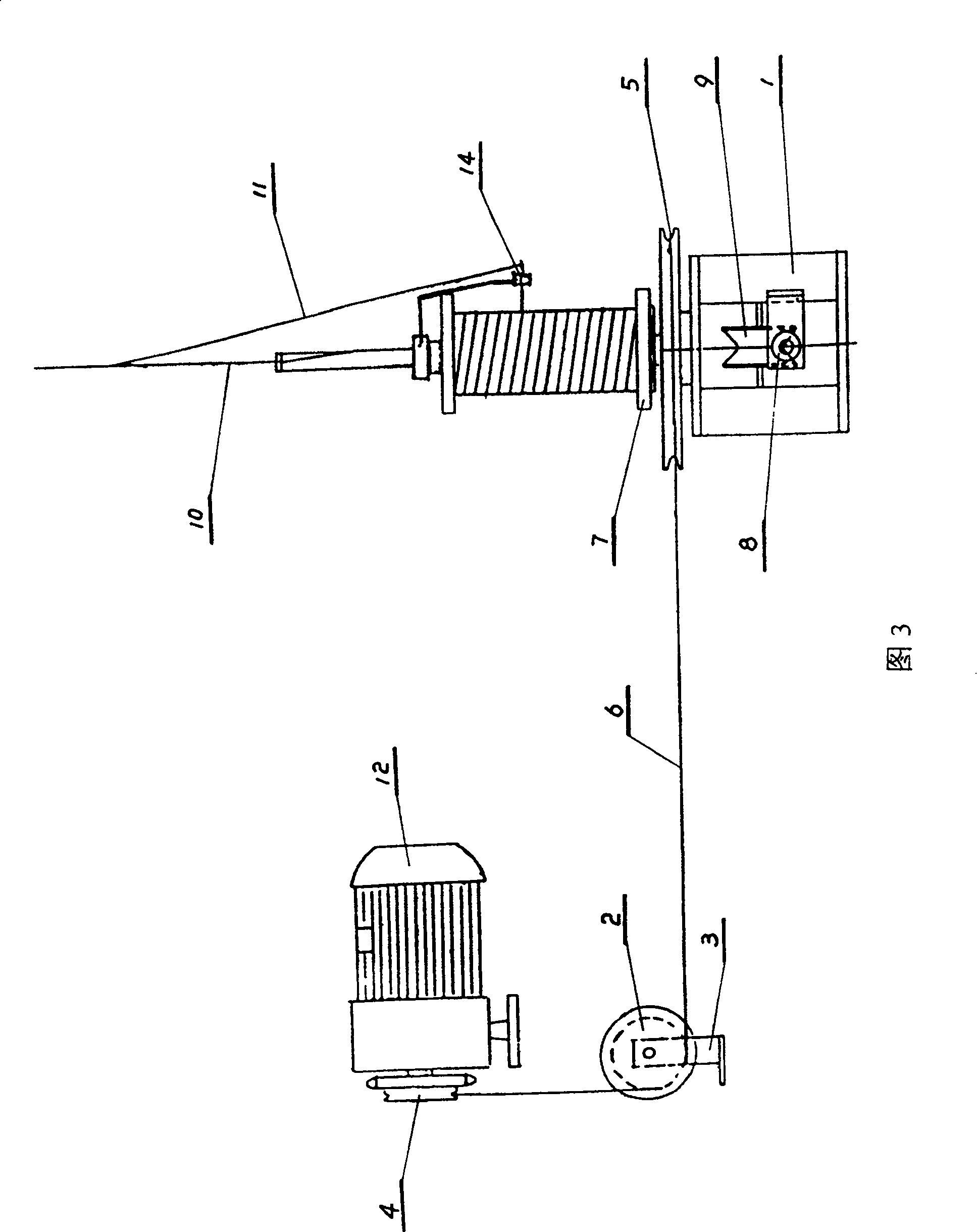

[0014] Referring to Fig. 3, the present invention comprises support 1, steering wheel 2, steering wheel bracket 3, driving and passive wheels 4,5, belt 6, and driving wheel 4 connects the take-up motor 12 in the original equipment, and steering wheel 2 is located at the steering wheel On the wheel bracket 3, the driven wheel 5 is located on the support 1, and the belt 6 connects the driving wheel 4, the steering wheel 2 and the driven wheel 5; The bottom is provided with a wire passing mold 8 and a core wire guide wheel 9; in the cable production process, when it is necessary to weave or wrap the shielding layer, start the weaving machine, and when the weaving disc is running, the take-up motor 12 is running at the same time. The belt 6 in the invention drives the driving and passive wheels 4 and 5 to rotate, and the ground wire reel 7 rotates at the same time, so that the ground wire 11 on it is wound around the core wire that enters through the wire passing mold 8 and the cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com