One steel wire stranded hollow coil, one medical apparatus produced with the same, and producing method thereof

一种空盘圈、绞合的技术,应用在制绳的辅助装置、应用、传感器等方向,能够解决增加扭转阻力、不能柔性实体线本体投入、增加重量等问题,达到高转动顺从能力、良好直线性感觉、高直线性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

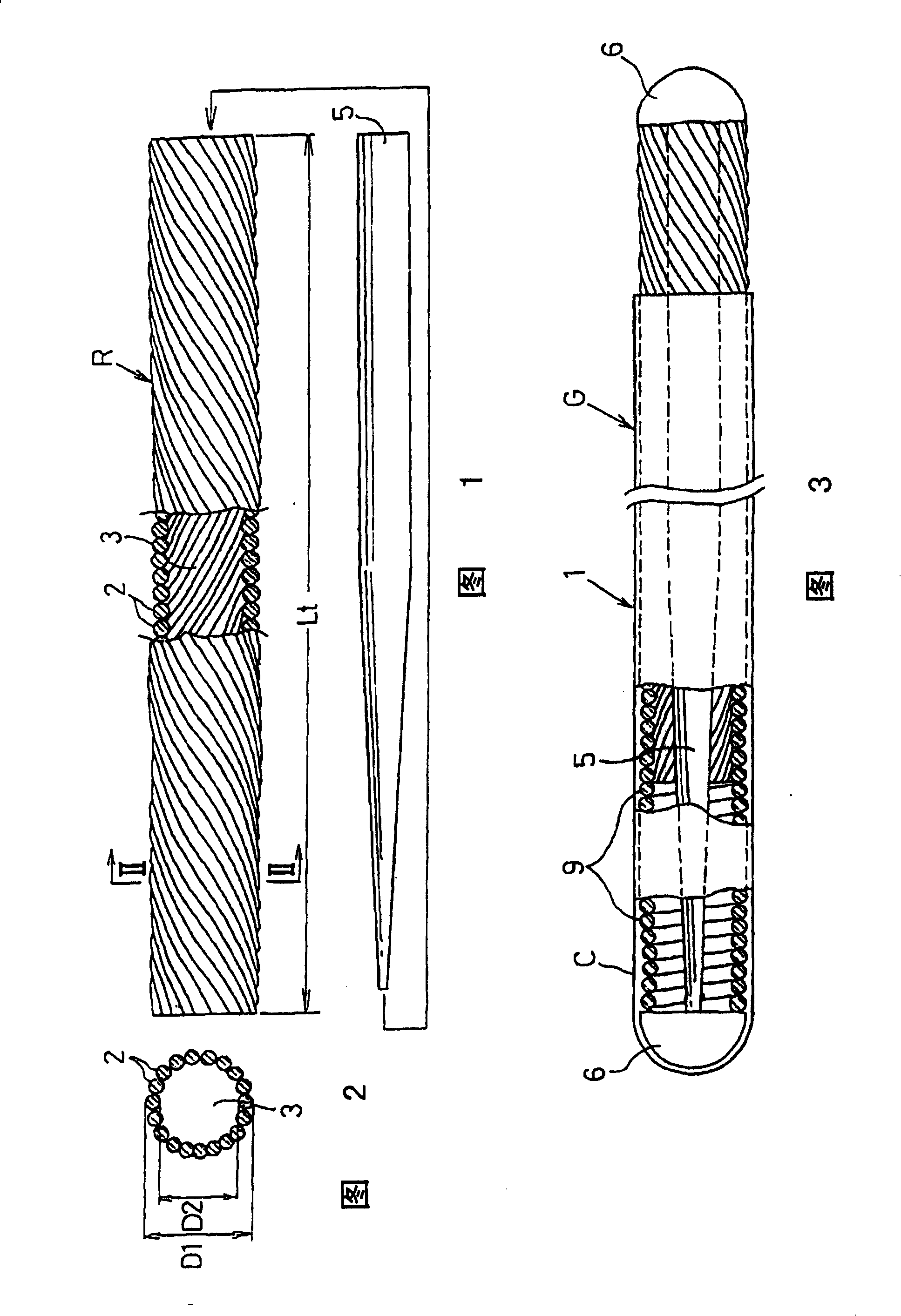

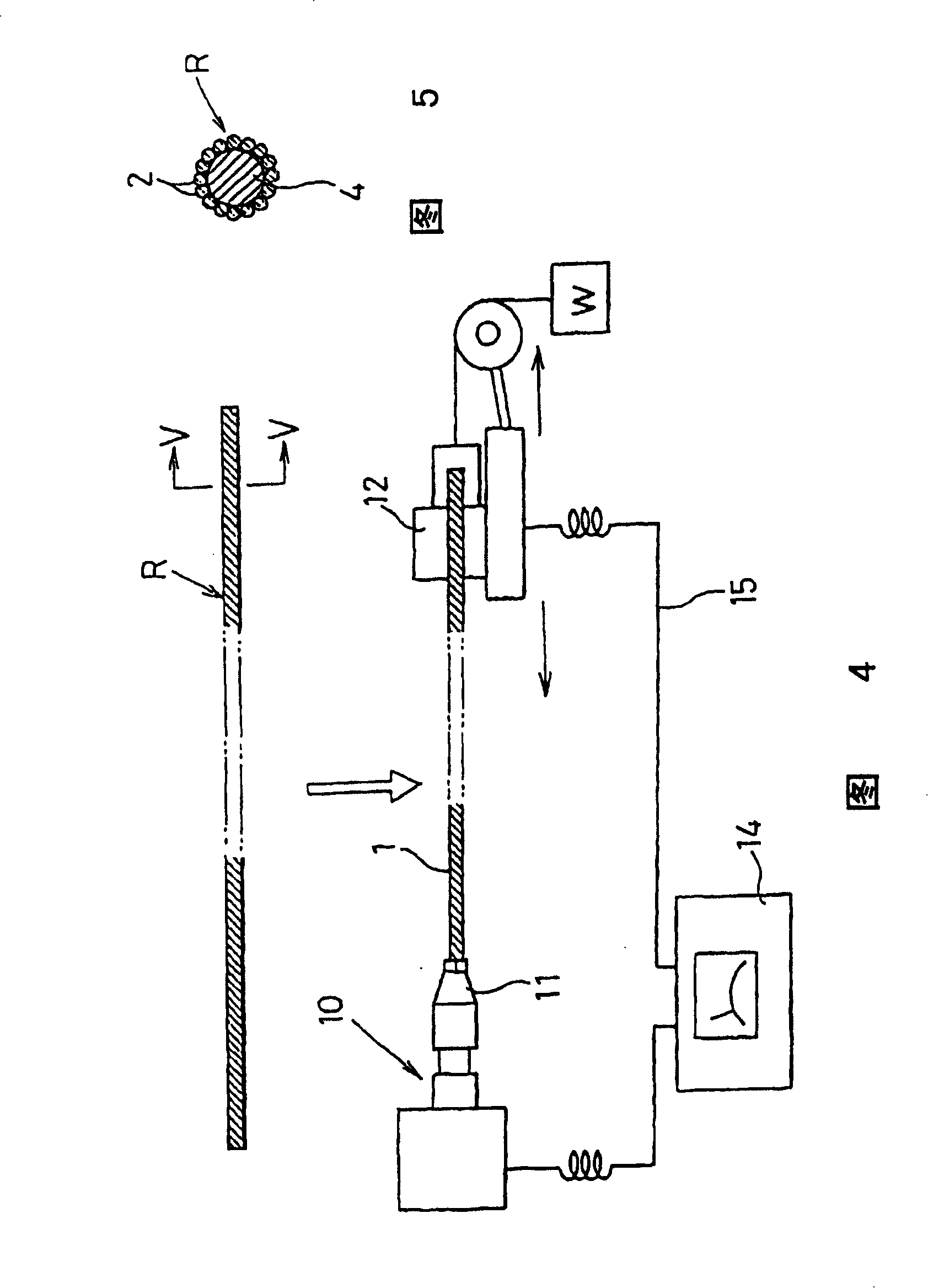

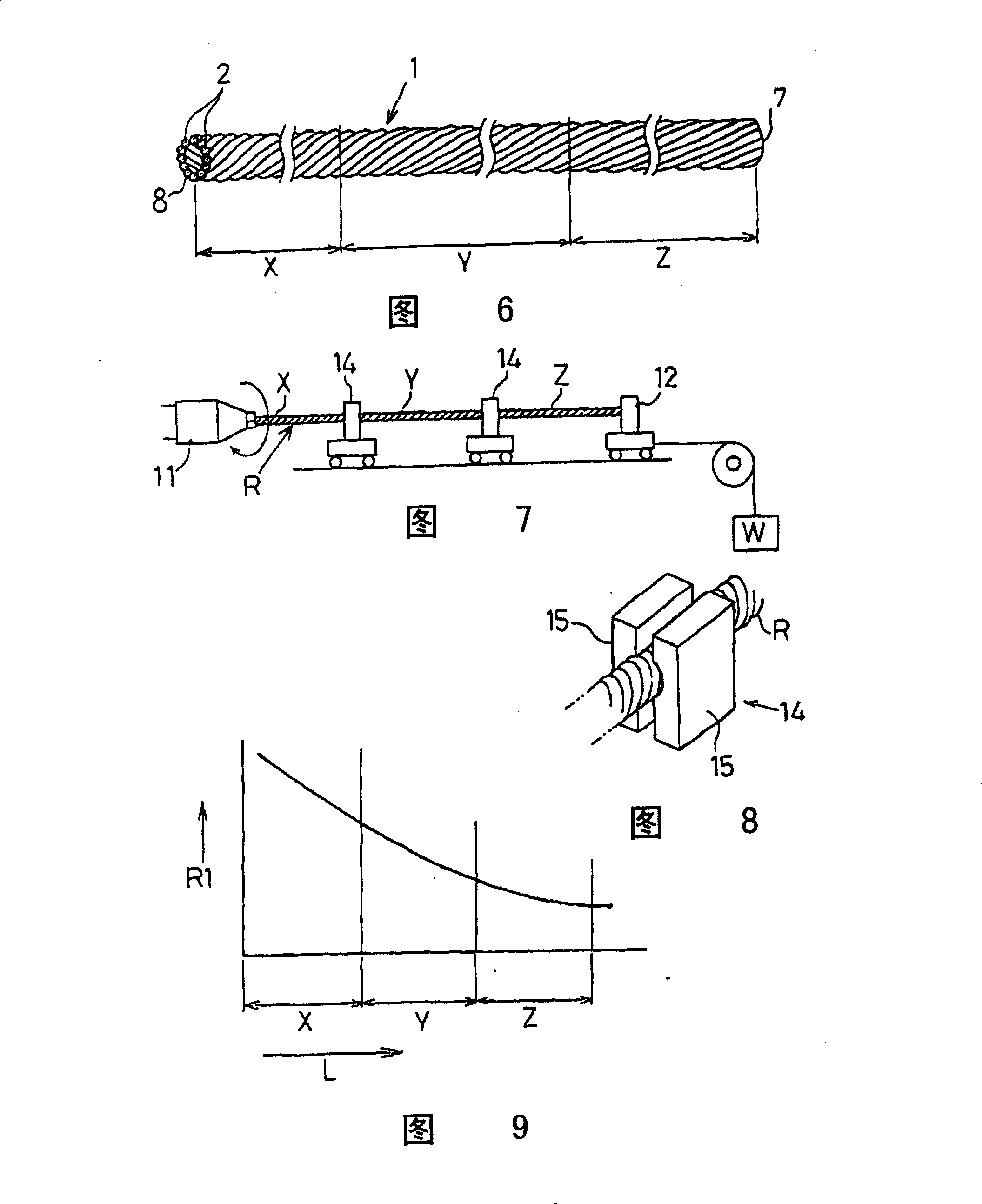

[0055] 1 to 5, the wire stranded hollow coil body 1 according to the first embodiment of the present invention manufactured by the first method of manufacturing the wire stranded hollow coil body 1 is described. In order to use an elongated elastic thin wire as a guide wire for medical use, a plurality of austenitic stainless steel coil wire elements 2 are twisted along a predetermined loop wire to form a flexible linear tube, the space of which is used as the central axis To the hollow part 3. The total length (Lt) of the flexible linear tube is measured to be approximately 1,000-1,500mm.

[0056] The 2 groups of coil wire elements are stranded under the action of anti-twisting torsional load (torque load), and heat treatment is performed to eliminate the residual stress that occurs during the stranding and drawing operations. The stranded hollow coil body 1 thus formed has a high linearity in the free state, and there is no unfavorable coiling or bulging phenomenon. The stranded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com