Water environmental protection laser film and its manufacturing method

A laser film, water-based technology, applied in decorative arts, office printing equipment, coatings, etc., can solve the problems of difficult positioning of printed patterns, waste of resources, difficult laser lines and printing positioning, etc., to achieve high industrial use value, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

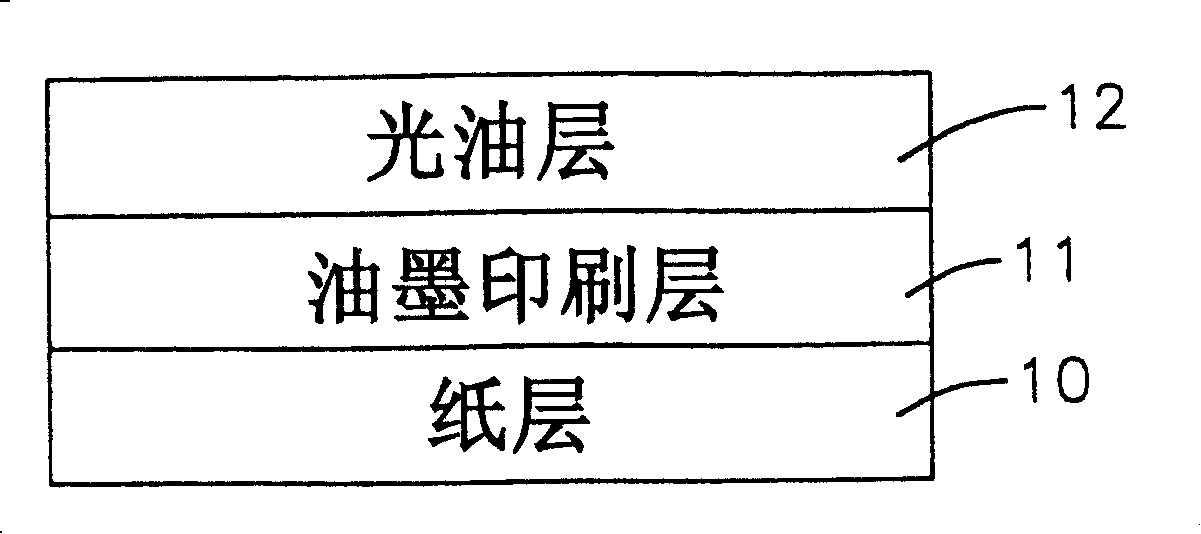

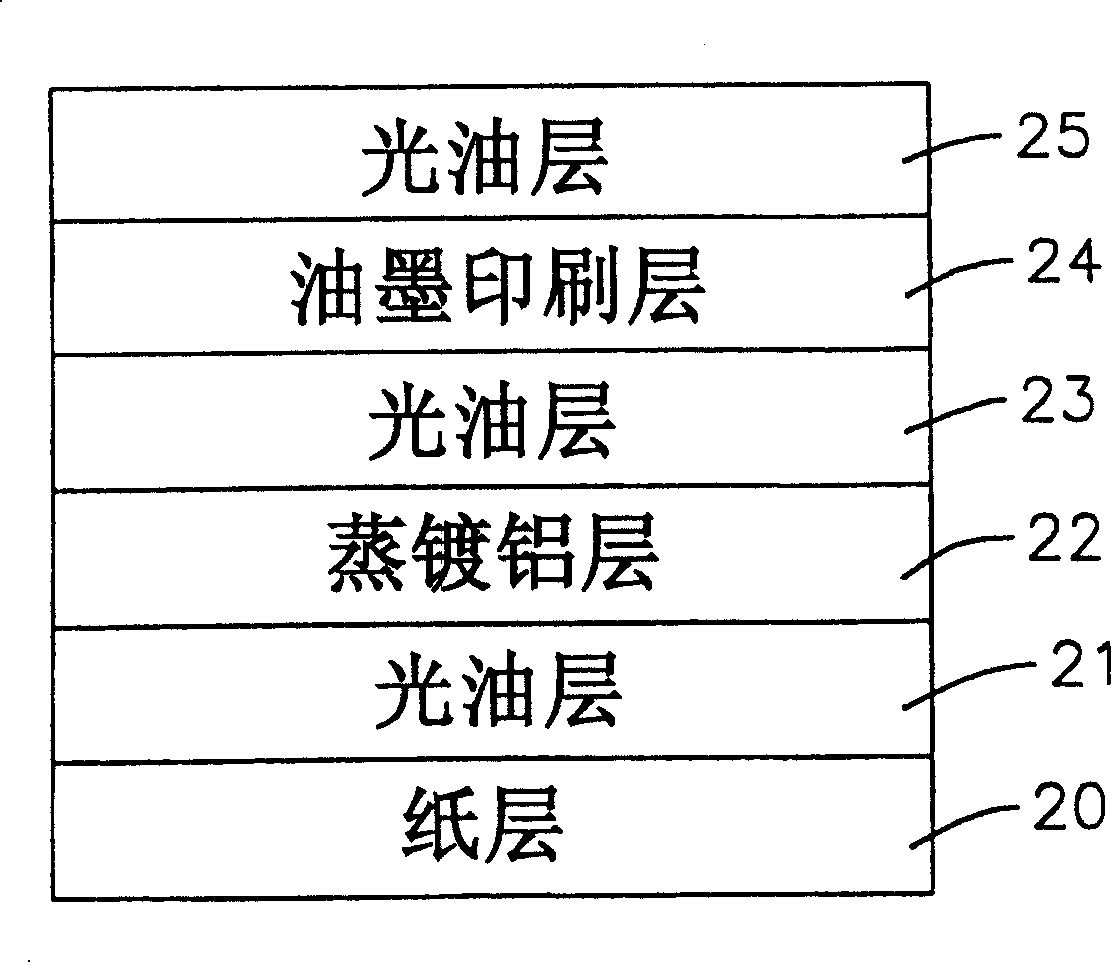

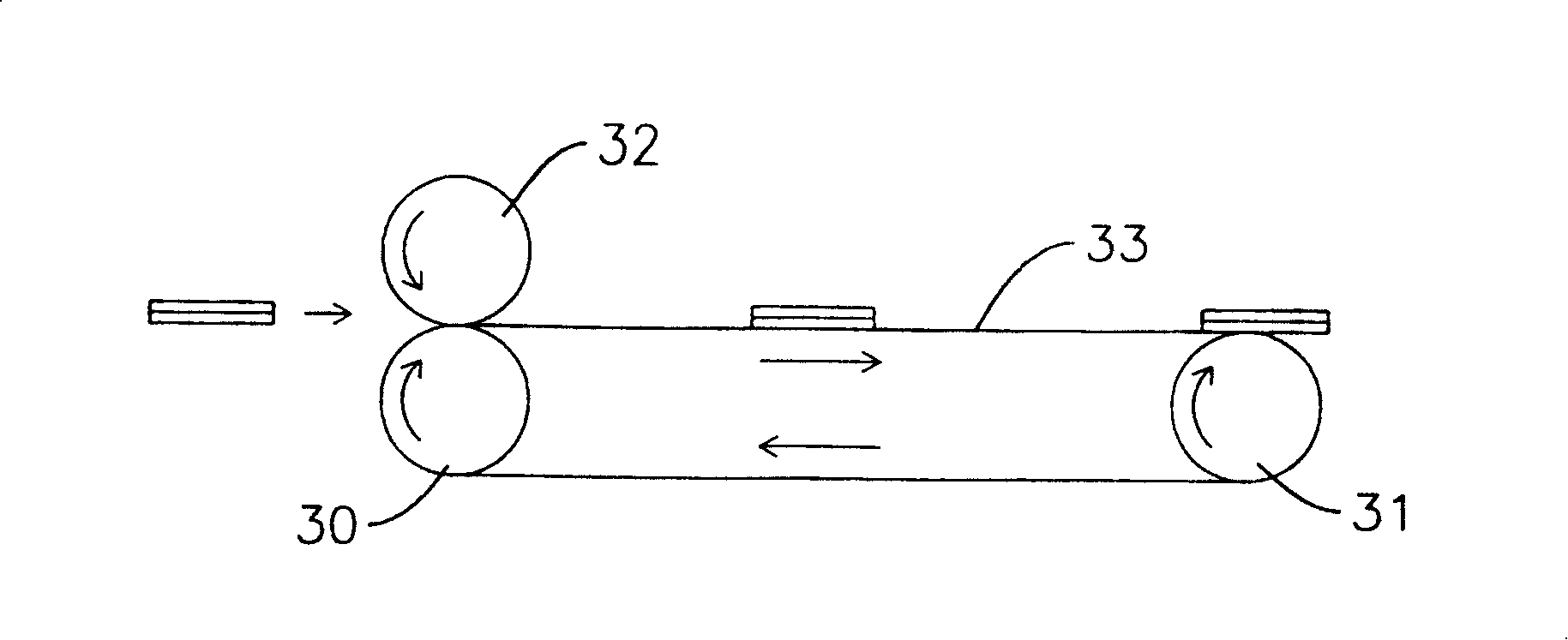

[0040] The water-based environmentally friendly laser film production method of the present invention is mainly to carry out ink printing treatment on the surface of paper or aluminum-coated paper, and then perform full or partial water-based laser lamination varnish coating and glazing on the treated surface sequentially. Mirror surface treatment and full or partial laser lamination.

[0041] Wherein the above-mentioned varnish can be about 42±2wt% of acrylic polymer (ACRYLIC COPOLYMER), about 55±2wt% of water heat-resistant matting oil or about 42±1wt% of acrylic polymer, soybean lecithin (SOYA BEAN OIL (LECITHUN )) about 3±1wt%, water about 55±1wt%, water-based laser laminating varnish or acrylic monomer about 50~60wt%, epoxy acrylic oligomer (EPOXY ACRYLATE OLIGOMER) about 40~50wt%, light Initiator PHOTOINOTIATOR about 5% non-thermoplastic varnish.

[0042]The present invention can also carry out comprehensive water-based laser lamination varnish coating, glazing surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com