Combination type pulley for arm support of portal hoist, maintaining and installing technique thereof

An installation process and combined technology, which is applied to portable hoisting devices, hoisting devices, mechanical equipment, etc., can solve the problems of long downtime, waste, and poor wear resistance of pulley rope groove rings, etc., and improve production efficiency , improve the utilization rate, easy maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

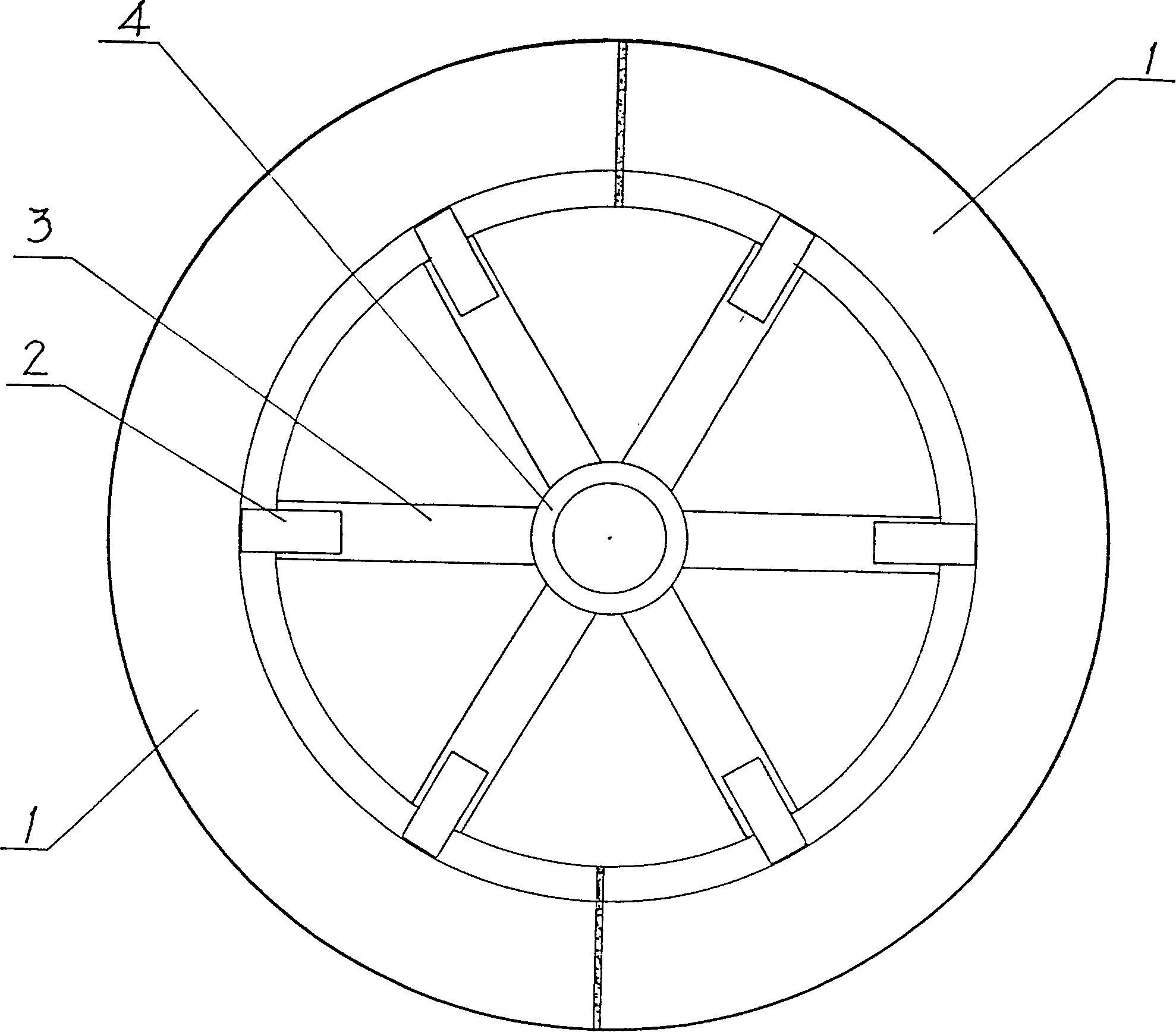

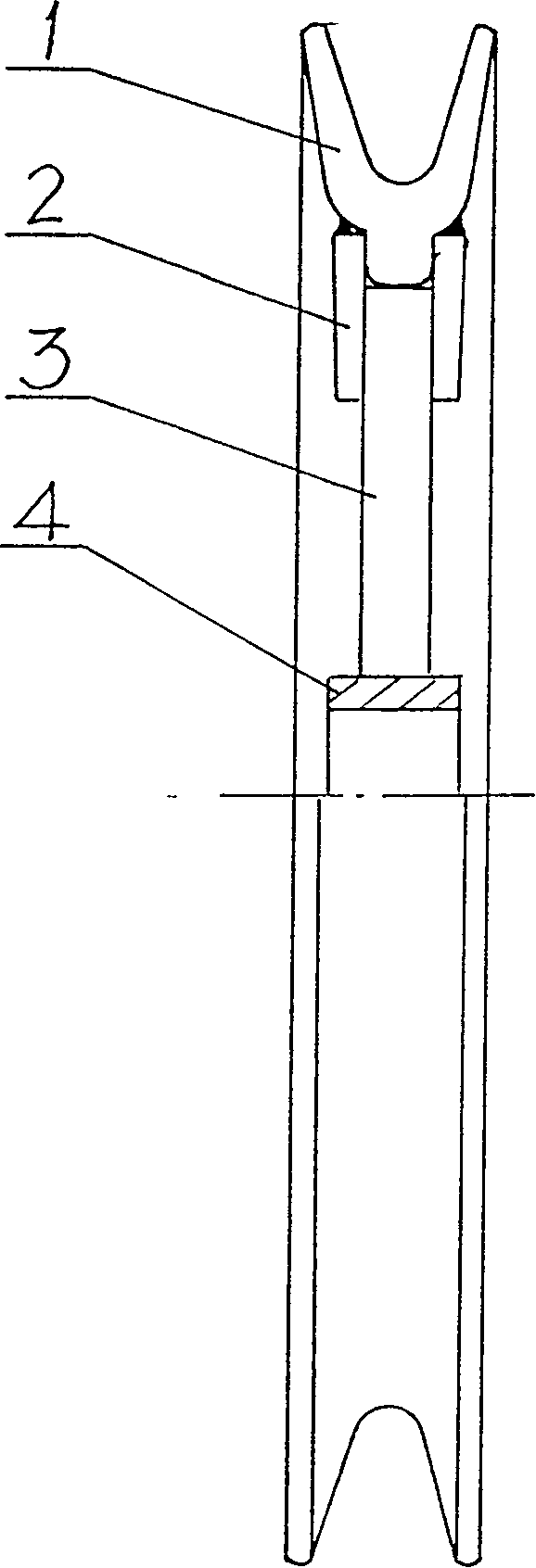

[0028] see figure 1 , be shaped on six spoke plates 3 on the large hump pulley hub 4 of the door machine jib. In order to facilitate the replacement of the pulley groove ring 1, the outer end surface of each web is spliced with a pulley groove ring 1 with a U-shaped groove 5 on the outer peripheral surface welded by two semi-circular splicing, see figure 2 , the pulley groove ring and each web are connected by welding, so that a new pulley groove ring can be replaced by cutting and welding. In order to increase the connection strength between the pulley groove ring and each spoke plate, welded reinforcing rib plates 2 are installed on both sides of the splice between the spoke plate and the pulley groove ring.

Embodiment 2

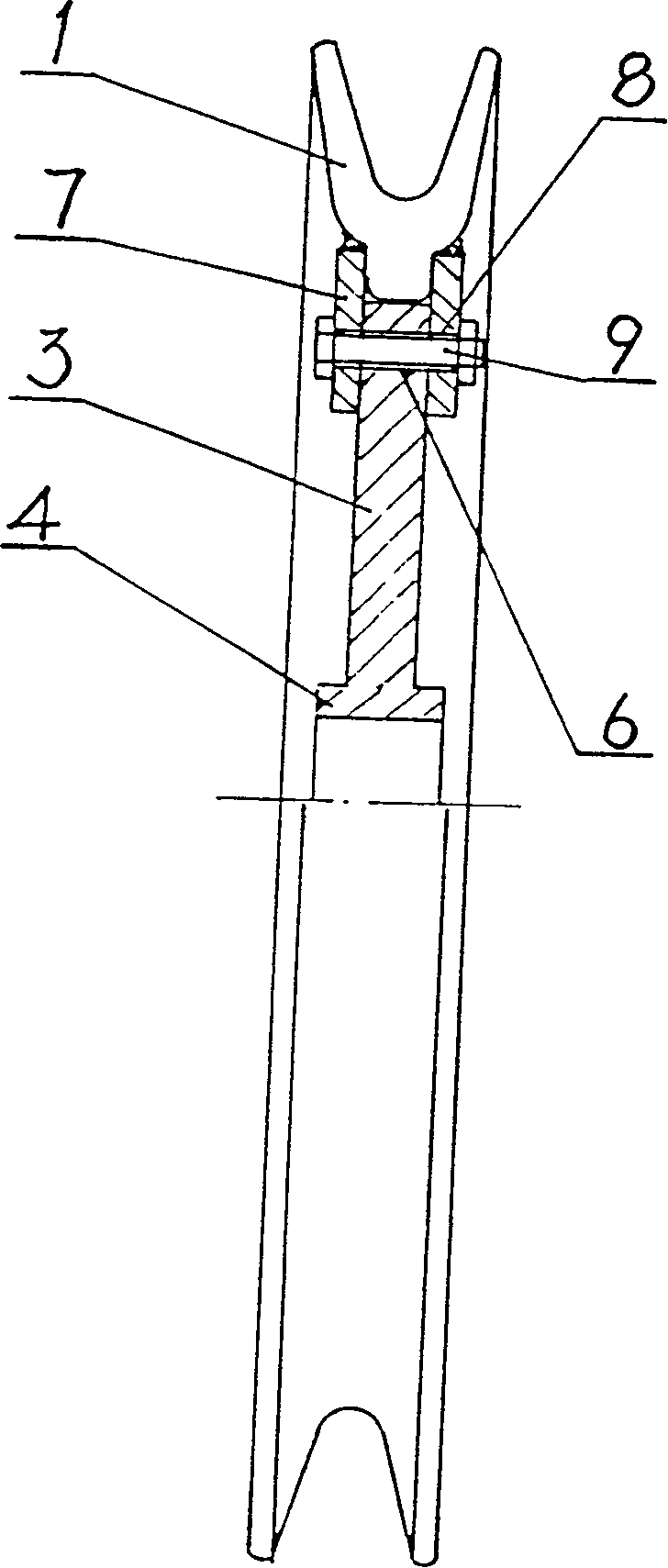

[0030] Another structure for splicing the pulley grooves is that through holes 6 are formed on the outer ends of each web, splints 7 are welded on both sides of the pulley grooves corresponding to each web, and splints are formed on the splints corresponding to the through holes on the webs. Through holes 8, fastening bolts 9 are installed in the through holes of the web plate and the splint plate. A connecting plate 10 and a fastening screw 11 are installed on the inner peripheral surface of the splicing part of the pulley groove ring, so that the purpose of replacing a new pulley groove ring can also be achieved through the disassembly and assembly of bolts and screws, such as image 3 and Figure 4 shown.

Embodiment 3

[0032] The combined pulley repair and installation process for the door crane jib has the following steps:

[0033] Welding maintenance installation process:

[0034] (1) Make a complete pulley groove, the inner circle of the pulley groove has welding grooves, and then cut the complete pulley groove into two half-ring pulley grooves;

[0035] (2) Use a gas welding gun to accurately cut the web along the inner circle of the damaged pulley groove, and cut off the damaged pulley groove from the web;

[0036] (3) Set the new half of the annular pulley groove ring on the spoke plate and fix it with electric spot welding, and then set the other half of the annular pulley groove ring on the spoke plate and fix the two half ring pulleys with a clamp. The groove rings are connected together, and the angle of the pulley groove ring is measured and adjusted with a measuring instrument so that it is perpendicular to the pulley shaft;

[0037] (4) Weld and fix the pulley groove ring on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com