Silicon-based electrode production process and energy storage device

A manufacturing process and electrode technology, which is applied in the manufacturing process of silicon-based electrodes, can solve the problems of volume expansion, inhibiting the surface treatment of interface reactants and electrode sheets, and other problems such as ink.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

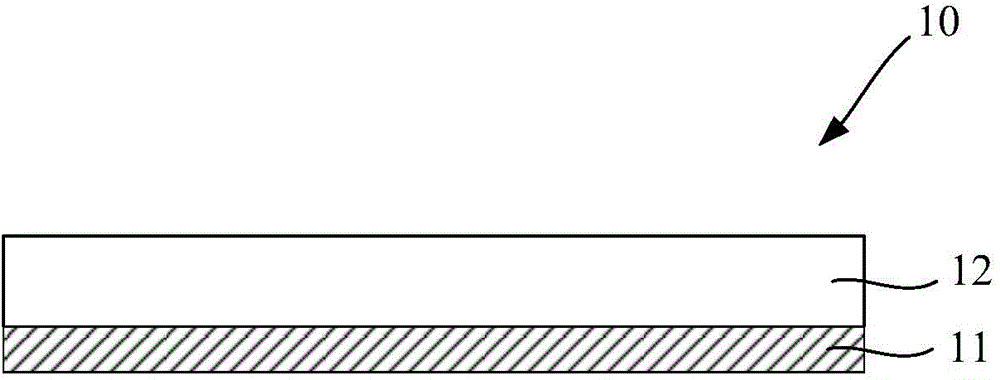

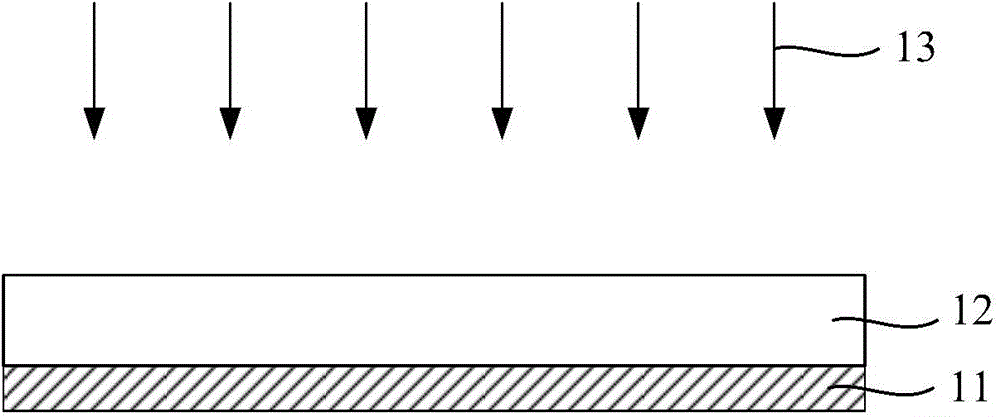

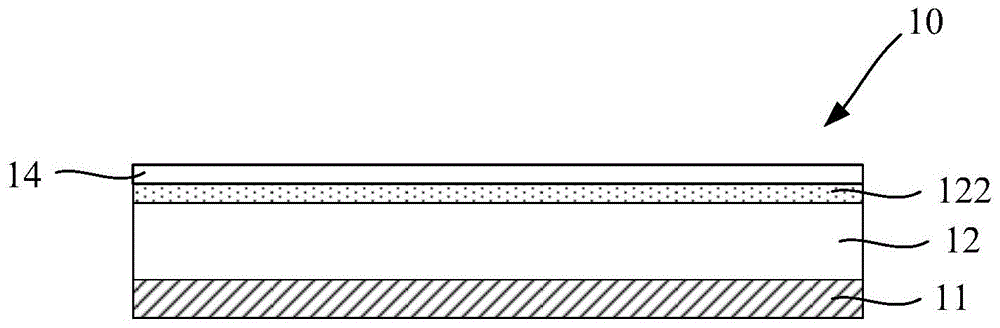

[0023] Please refer to Figure 1 to Figure 3 , showing the schematic diagram of each step in the fabrication process of the silicon-based electrode. Such as figure 1 As shown, a conductive substrate 11 is provided first, and then a silicon layer 12 is coated on the conductive substrate 11 . Wherein, the conductive substrate 11 is a metal foil, and copper foil is used as the conductive substrate 11 in the embodiment of the present invention. The step of coating the silicon layer 12 on the conductive substrate 11 includes: first forming a coating of the silicon composition on the conductive substrate 11 by coating, and then drying the coating formed on the conductive substrate 11. , the silicon layer 12 is formed on the conductive substrate 11 . In this embodiment, the means of coating include screen printing, spin coating, bar coating, blade coating, roller coating) or dip coating (dipcoating), however, in the present invention, the means of forming the coating on the condu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com