Preparation method of star shaped copper sulfide

A copper sulfide and surfactant technology, applied in copper sulfide and other directions, can solve the problems of non-uniform morphology, wide product size distribution, and large amount of surfactant, and achieve no environmental pollution, mild and easy-to-control conditions, and no energy. The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Preparation contains 0.1mol / L Cu 2+ The microemulsion A, wherein the mixed mass content of surfactant (12-3-12) and alcohol is 25%, the molar ratio ω of water and surfactant 0 is 5, and the rest is the content of the oil phase; the content of each component of the corresponding emulsion contains and Cu 2+ S with a molar ratio of 7.5 2- microemulsion B. While stirring, add emulsion B to emulsion A, stop stirring when brown color appears, and store at room temperature for 24 hours. Centrifugal separation, washing and drying to obtain needle-shaped copper sulfide nanocrystals. Such as figure 1 . Under this condition, star-shaped copper sulfide has not been obtained due to the limitation of the emulsion structure.

Embodiment 2

[0032] Preparation contains 0.2mol / L Cu 2+ The microemulsion A, wherein the mixed mass content of surfactant (12-3-12) and alcohol is 25%, the molar ratio ω of water and surfactant 0 is 30, and the rest is the content of the oil phase; the content of each component of the corresponding emulsion contains and Cu 2+ S with a molar ratio of 30 2- microemulsion B. While stirring, add emulsion B to emulsion A, stop stirring when brown color appears, and store at room temperature for 4 hours. Centrifugal separation, washing and drying to obtain star-shaped copper sulfide nanocrystals. Such as figure 2 . It can be seen that the increase of water content changes the structure of the emulsion and affects the morphology of the product, but because the time is too short, the crystallinity is not good.

Embodiment 3

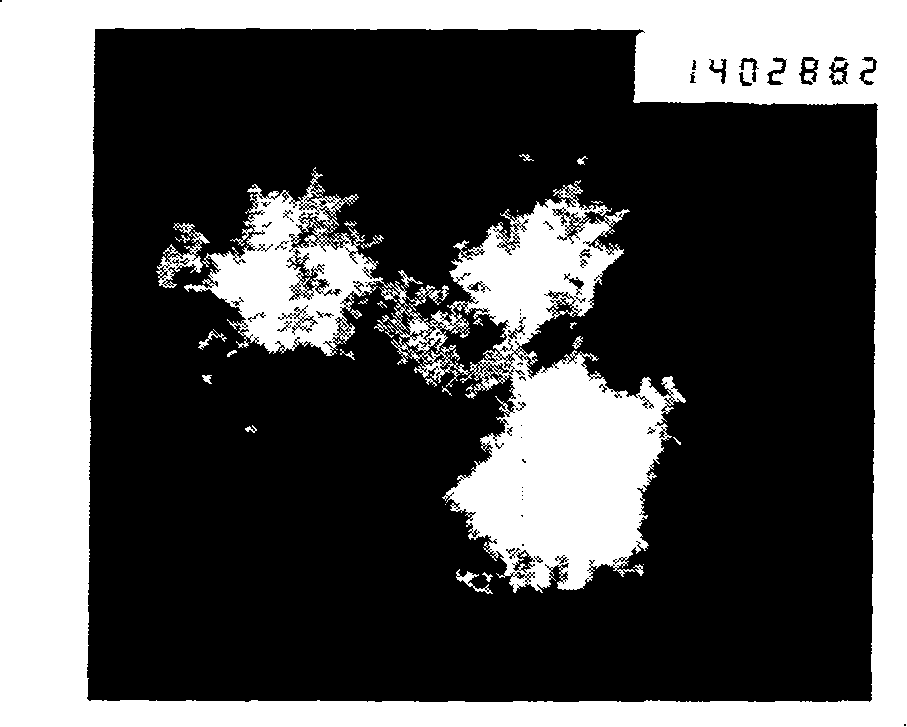

[0034] Preparation contains 0.2mol / L Cu 2+ The microemulsion A, wherein the mixed mass content of surfactant (12-3-12) and alcohol is 25%, the molar ratio ω of water and surfactant 0 is 30, and the rest is the content of the oil phase; the content of each component of the corresponding emulsion contains and Cu 2+ S with a molar ratio of 25 2- microemulsion B. While stirring, add emulsion B to emulsion A, stop stirring when brown color appears, and store at room temperature for 12 hours. Centrifugal separation, washing and drying to obtain star-shaped copper sulfide nanocrystals. Such as image 3 . It can be seen that when the aging time is long enough, the crystallinity is intact.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com