Heating power pump

A heat pump and pump body technology, applied in the field of energy exchange devices, can solve the problems of low energy transfer and conversion rate, high cost, high energy consumption, etc., achieve energy saving effects and improved heat transfer effects, small heat loss, and high capacity Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

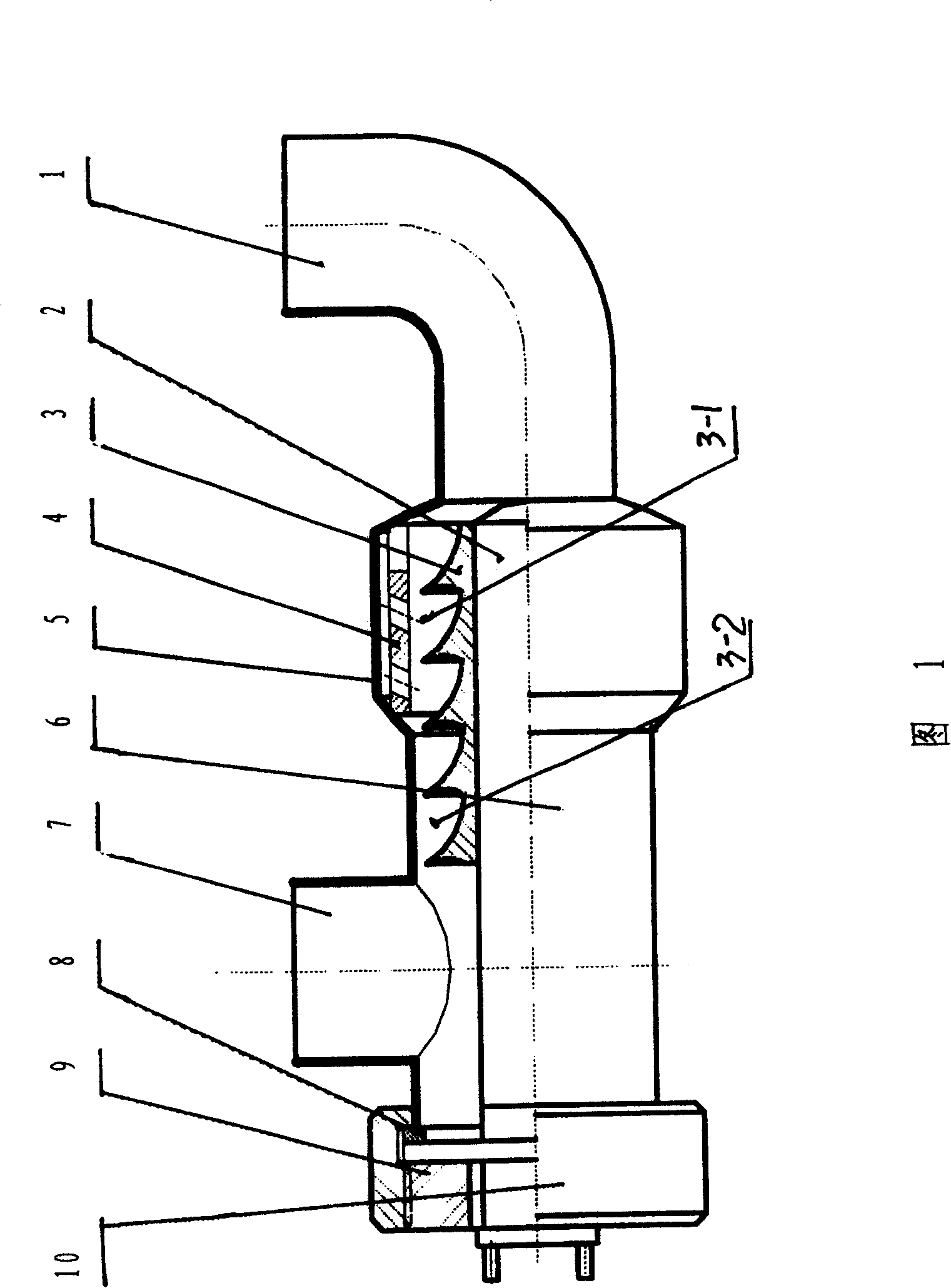

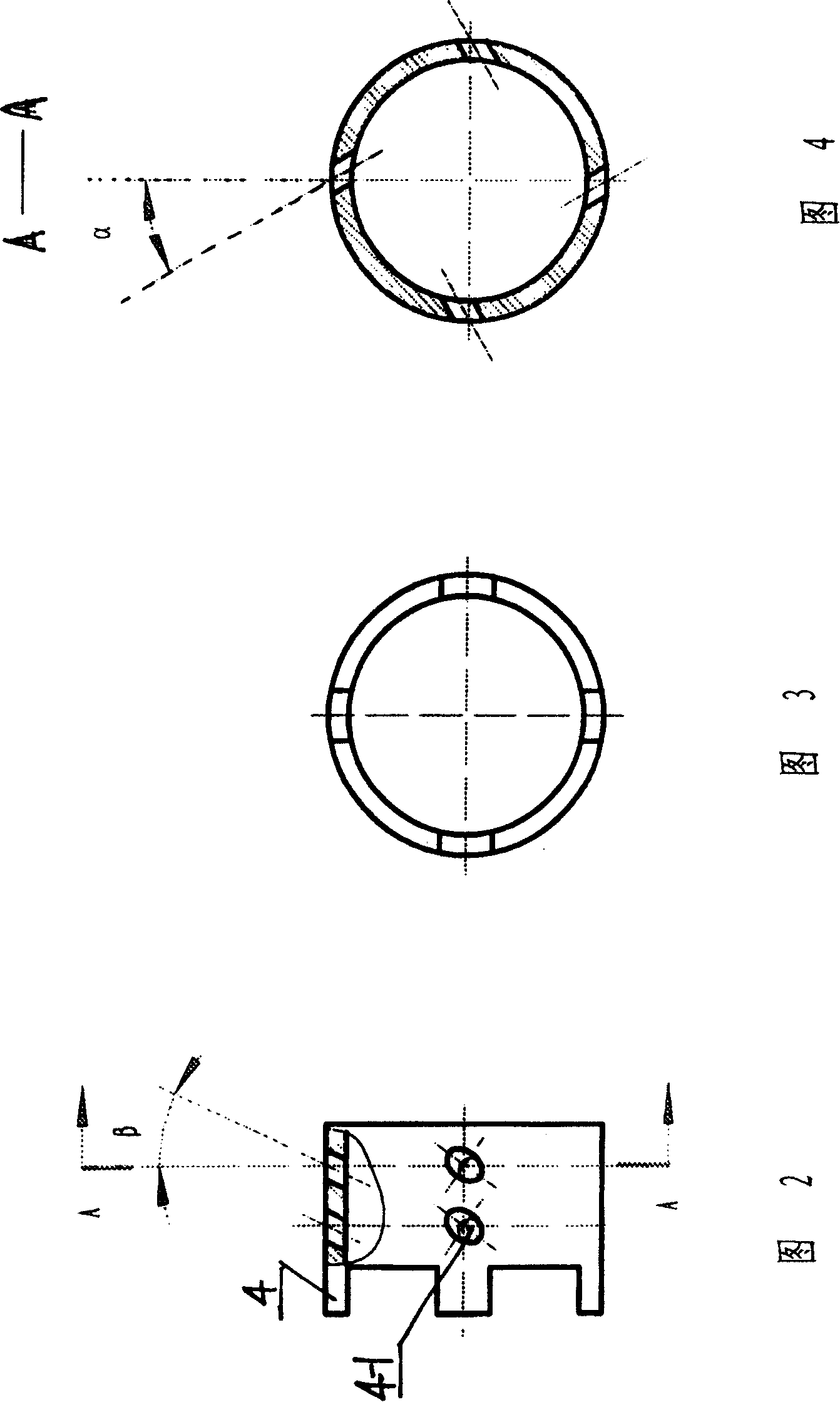

[0016] Embodiment: with reference to Fig. 1-Fig. 4. It can be seen from Fig. 1 that this is a heat pump whose heat source device is an electric heat source device. Here, the pump body consists of a radial guide housing 5 and an axial guide housing 6 . The electric heat source device 2 is located in the center of the pump body, its right half is located in the central hole of the axial flow guide 3, and the end of the left half extends out of the axial flow guide shell 6 and has a terminal. The end screw hole 10 is fixed on the left port of the axial guide housing 6. There is a circumferential groove in the end screw hole 10, and a rubber pad 8 which acts as a sealing medium is embedded in the groove, and passes through the end screw hole 10. The connected inner nut 9 is fixed. The medium outlet 7 is located on the side wall of the axial guide shell 6, the radial guide 4 is sleeved on the outside of the axial guide 3, and is covered in the radial guide shell 5, the radial gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com