Built-in robot

A robot and portable robot technology, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as inability to use, achieve the effect of reducing prices, reducing production costs, and improving the quality and efficiency of production operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

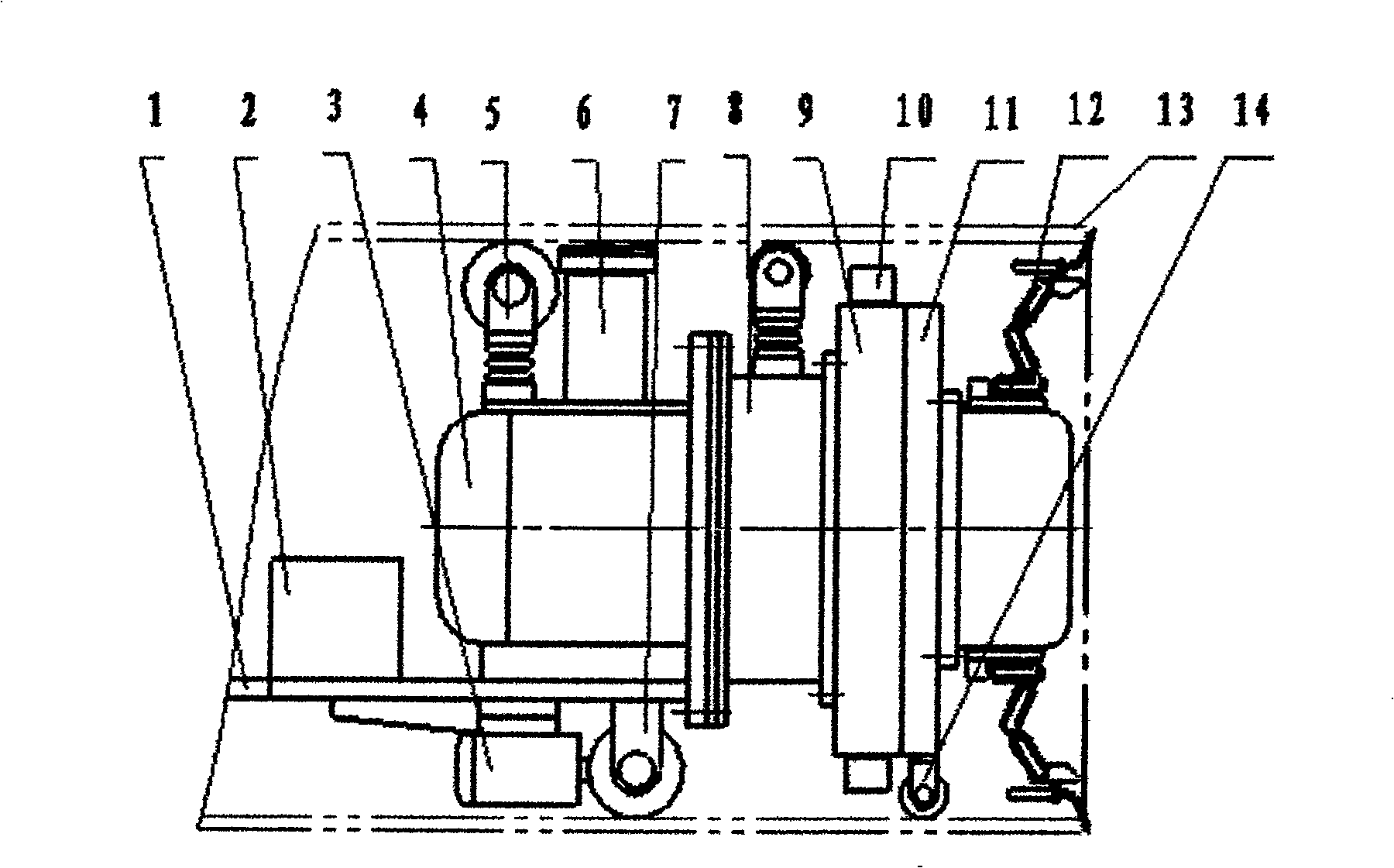

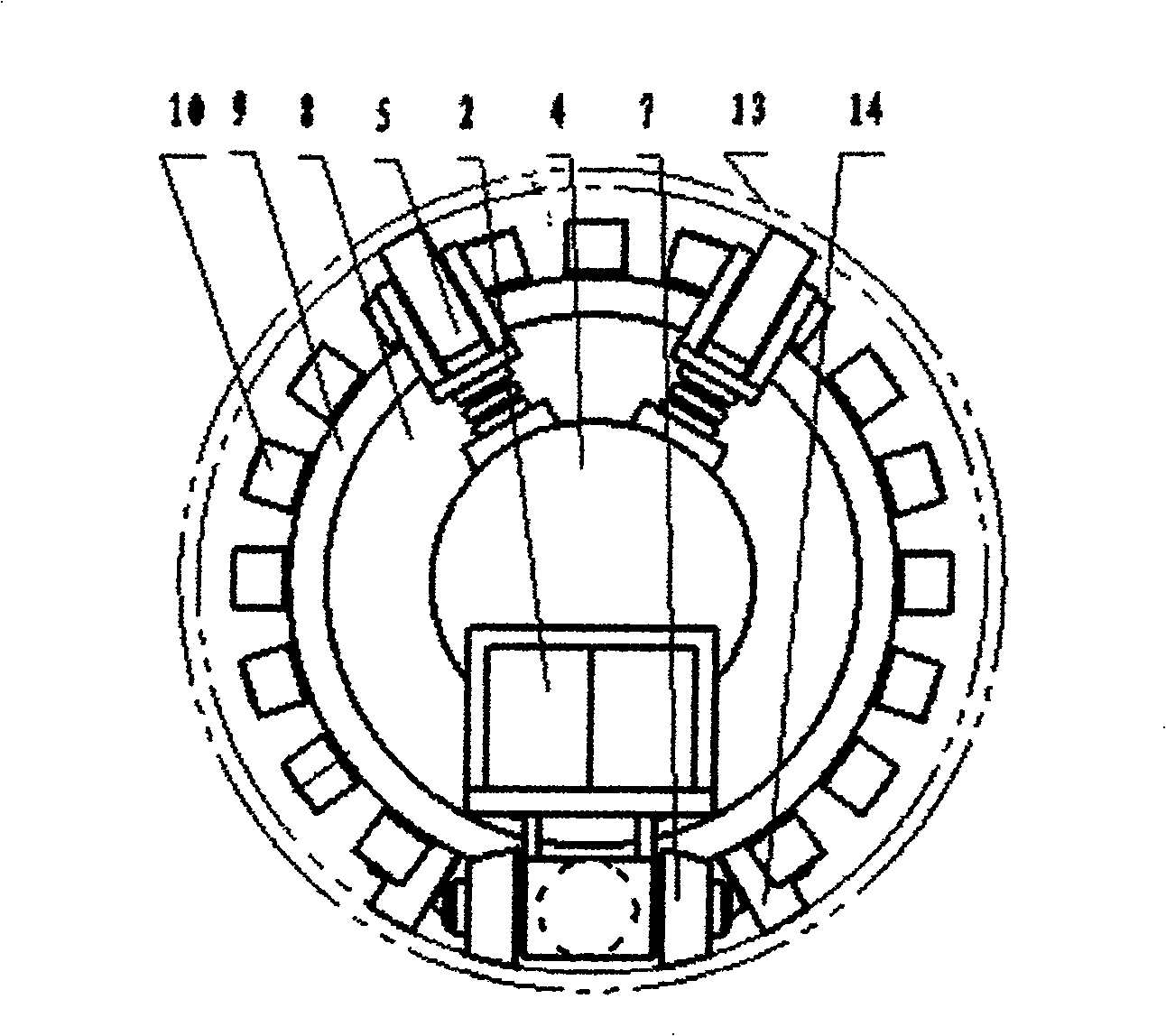

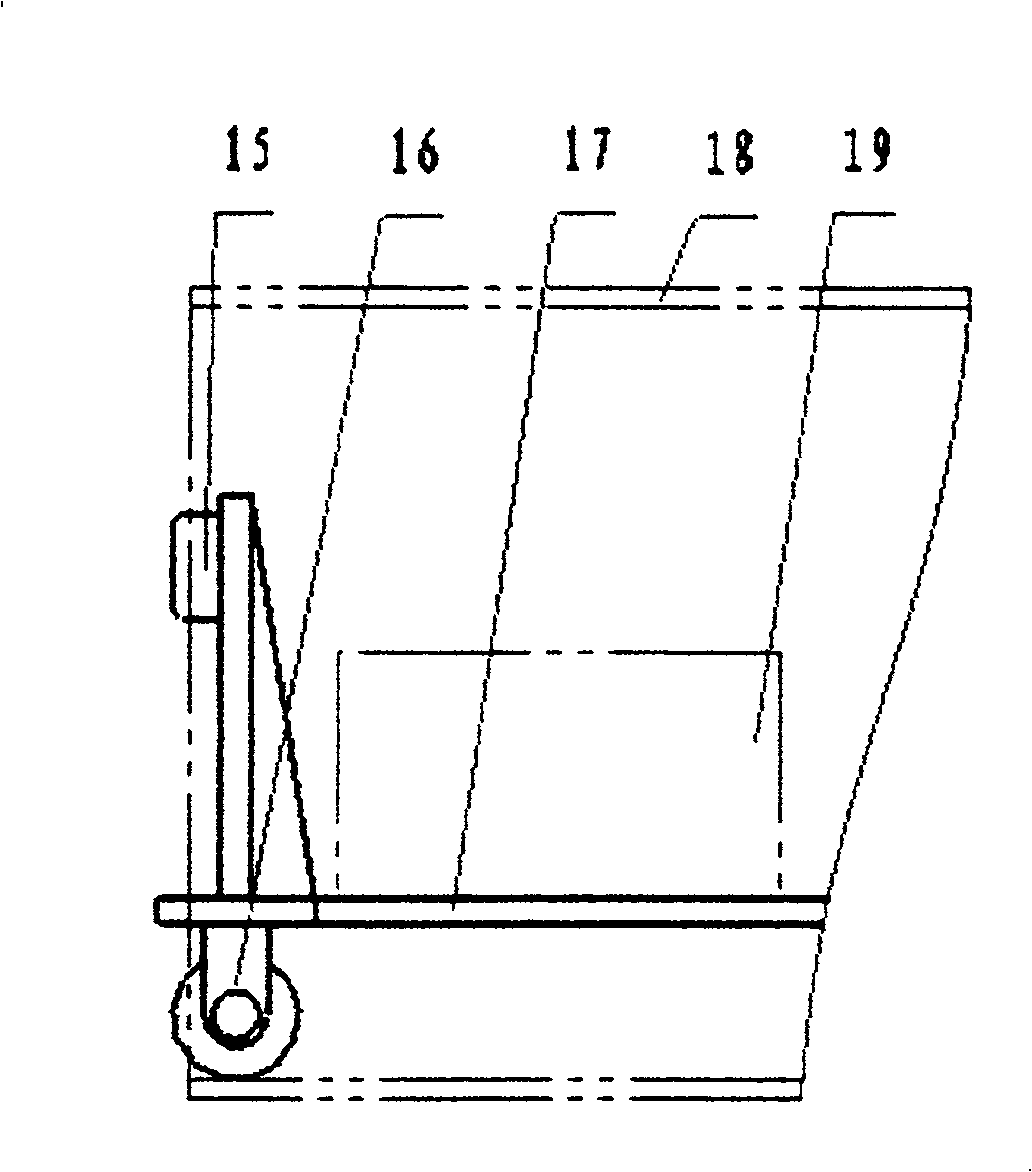

[0017] Such as figure 1 As shown, the trolley of the operation box is hinged to the mounting plate of the positioning motor. The equipment for production operations (such as air compressors, electric welding machines, and flaw detectors) is installed on the trolley. The operation box is installed on the trolley. Traveling motor, positioning motor, electromagnet, and robot controller are connected. It can be seen from the figure that the locator is the load-bearing body of the robot in the tube. It consists of a turntable motor, a reduction gear set, a turntable, a gear mounting plate, a positioning block, a spring, a positioning block guide tube, a positioning plate, a cam plate, a positioning screw spline shaft, a rolling bearing, It is composed of connecting short sleeve and positioning motor. The traveling mechanism is composed of a guide wheel, a pressing wheel, a traveling wheel, a traveling motor, a traveling reducer and an electromagnetic brake. The guide wheel is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com