Tube draught transportation installation method and apparatus

An installation method and pipe technology, applied in mechanical equipment, pipeline laying and maintenance, pipes/pipe joints/pipe fittings, etc., can solve the problem of increasing supporting funds for construction equipment, auxiliary construction time and pipeline construction period, slow hauling speed, and dangerous To solve problems such as high reliability and achieve the effect of improving production and labor conditions, reducing labor intensity, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

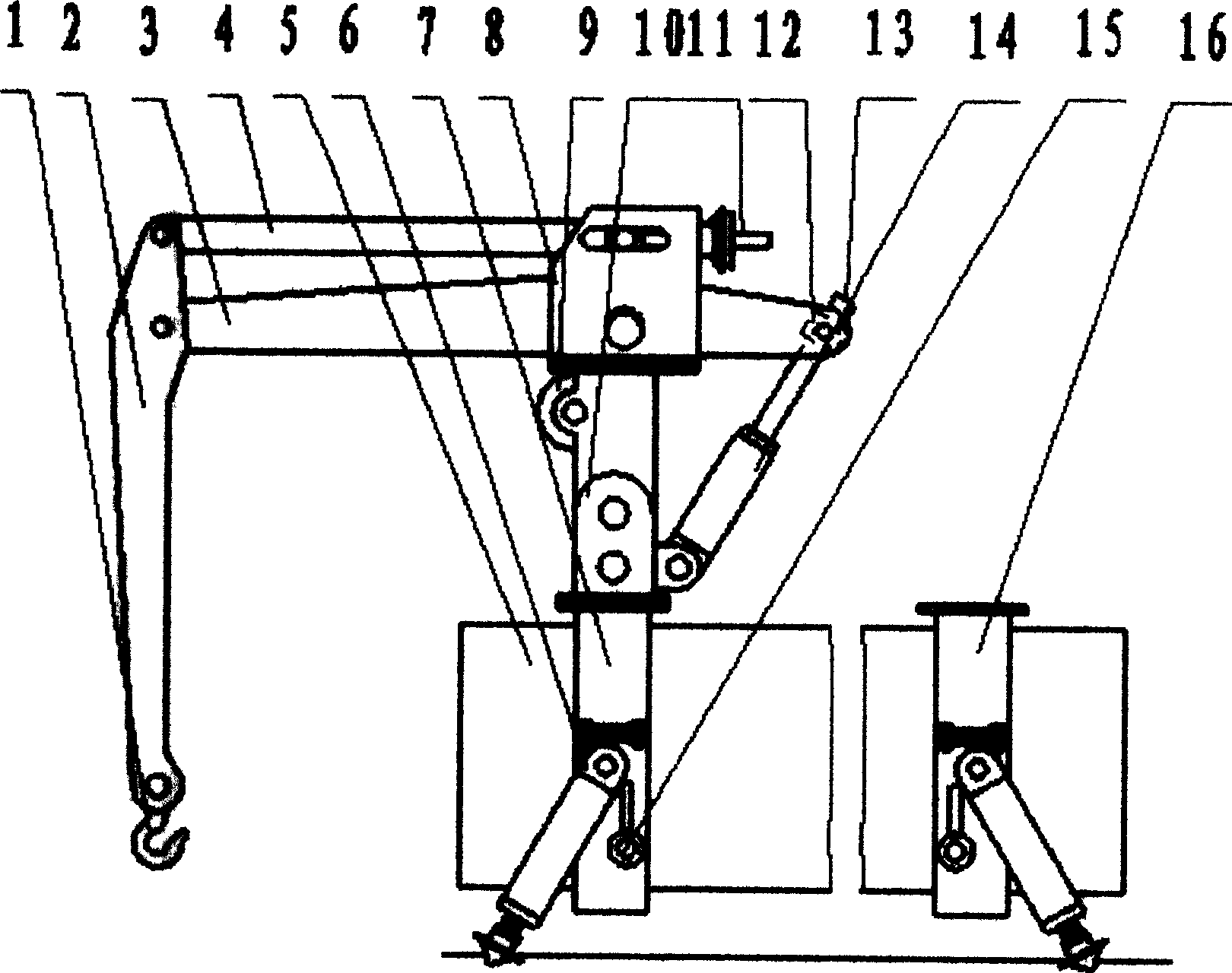

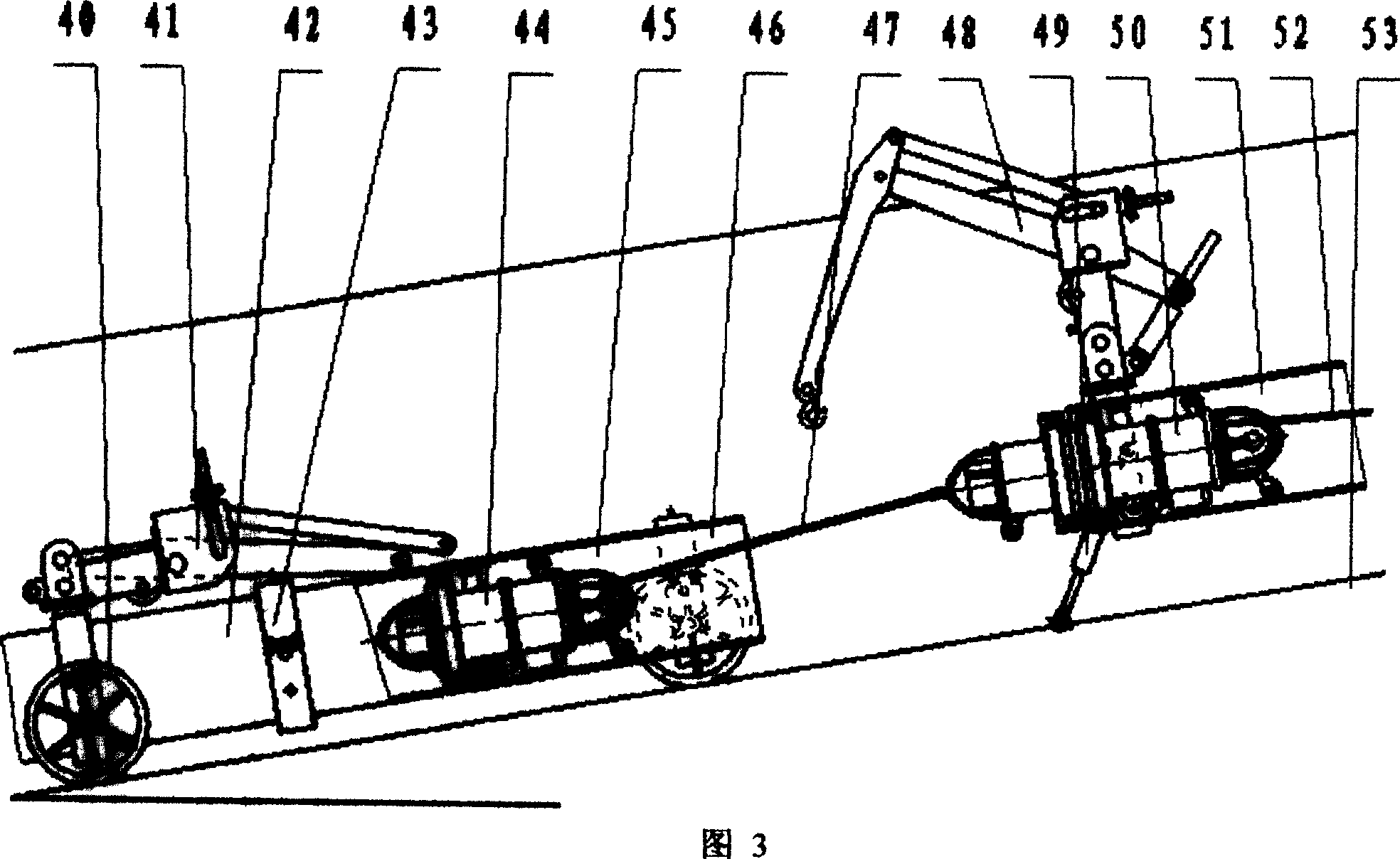

[0017] The following examples illustrate the pipe traction, transportation and installation method and equipment of the present invention.

[0018] The pipe traction transportation installation method described in the present invention comprises:

[0019] (1) According to the natural slope of mountains, hills and loess plateaus, excavate pipes and install pipe trenches, and bury ground anchors at the highest points of natural slopes of mountains, hills and loess plateaus;

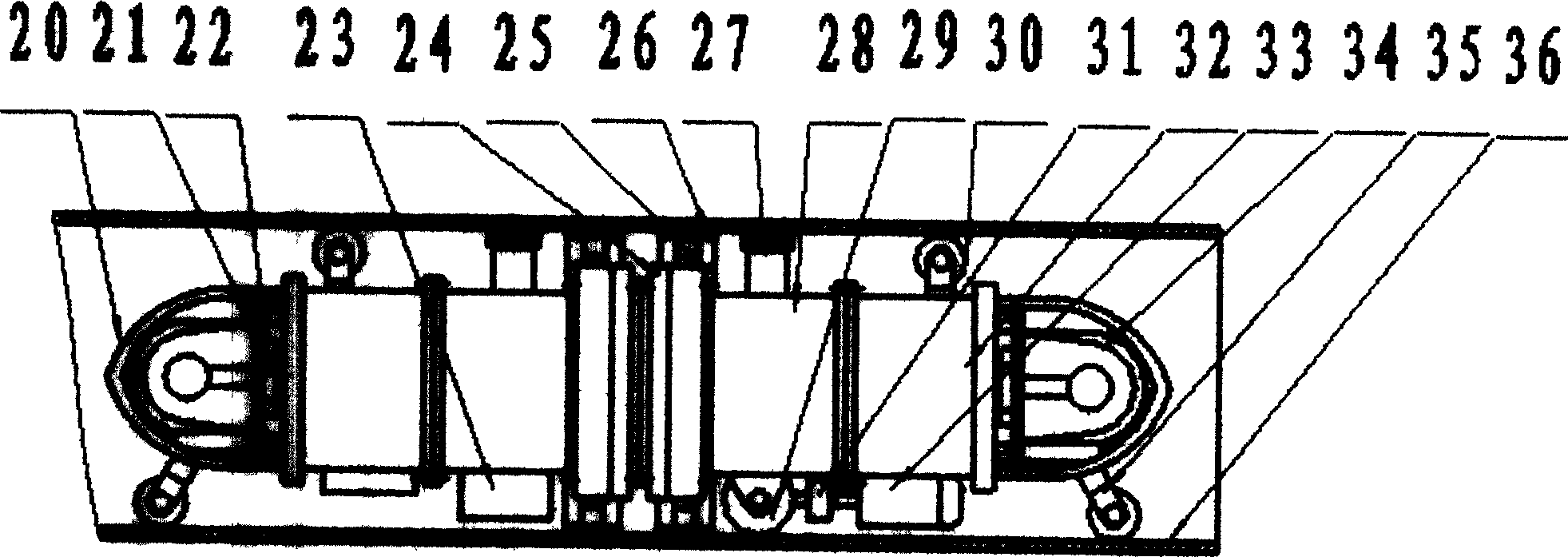

[0020] (2) The first pipe to be transported and installed is placed at the lowest end of the natural slope of mountains, hills, and loess plateaus, and a double-positioning pipe tractor is placed in the first pipe, near the left nozzle of the pipe. Operate the first locator of the double-positioning pipe retractor to push out the positioning block, and the friction between the positioning block and the pipe wall will fix the double-positioning pipe retractor at the left end of the first pipe;

[0021] (3) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com