Steel induction heating solid phase welding method and butt welding machine tool

A technology of induction heating and welding method, which is applied in the direction of welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of increasing welding workload and labor intensity of welding workers, shortening steel pipe welding time, and affecting the pipeline installation period, etc., to achieve improvement Production labor conditions, improvement of welding production efficiency, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

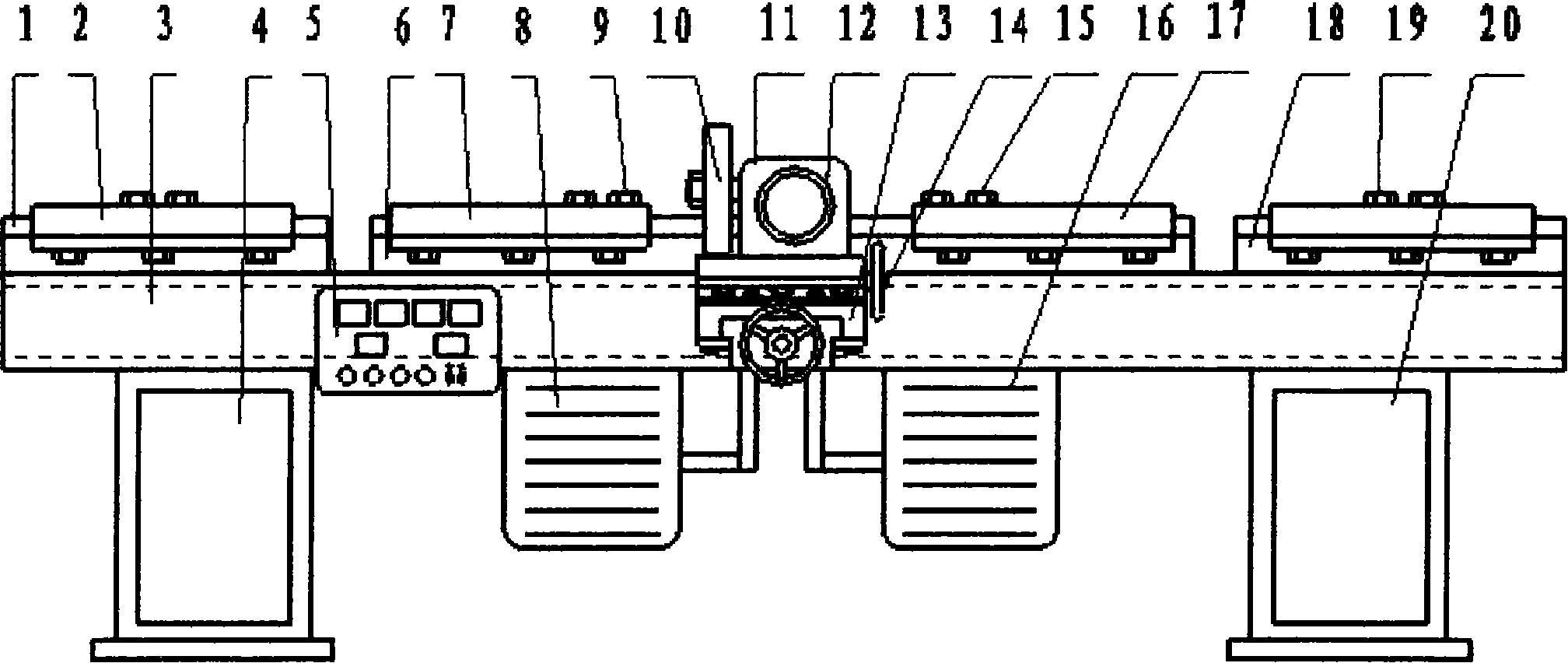

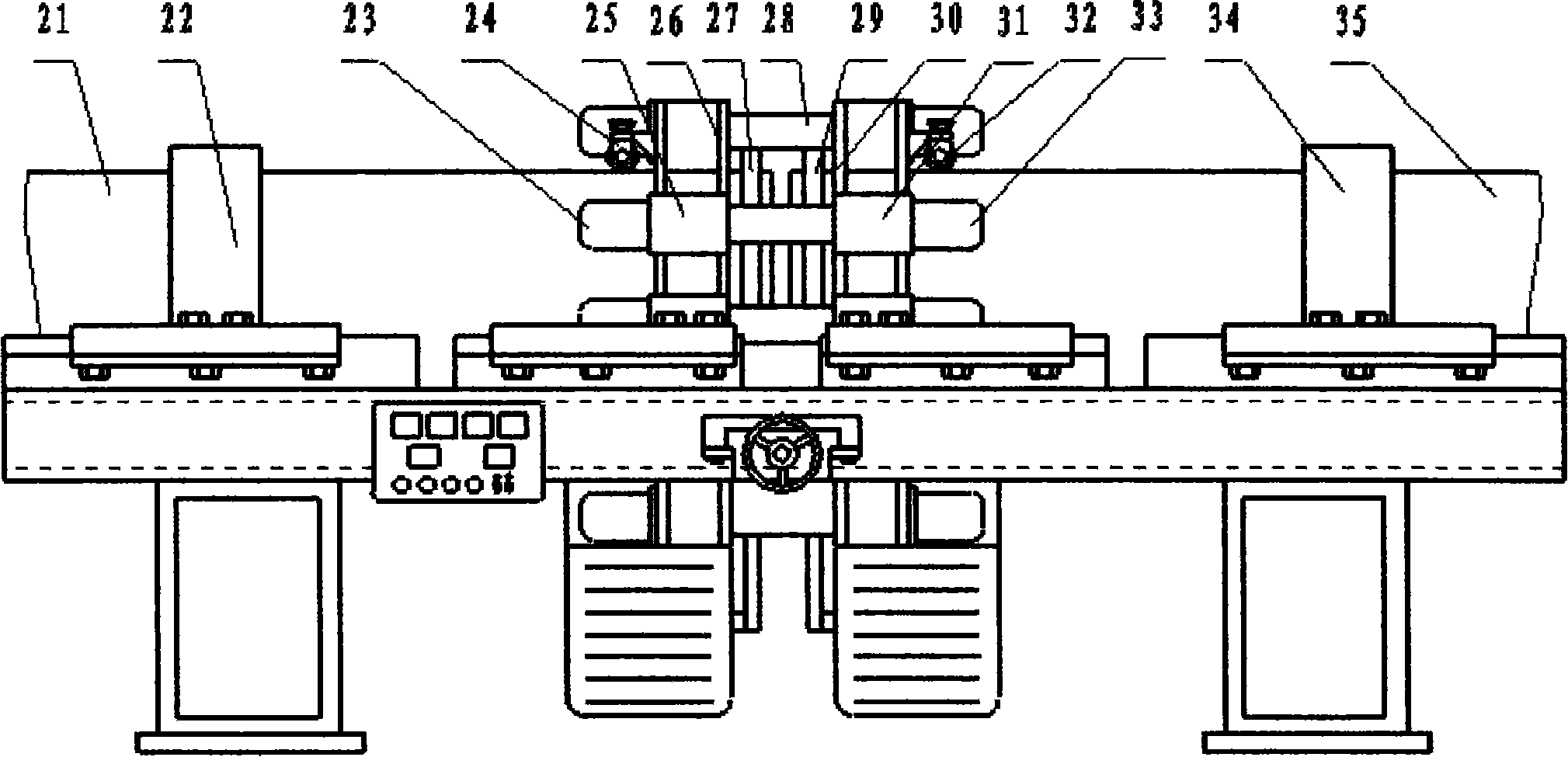

[0042] The butt welding machine is used for butt welding of steel pipes, rails, and round steel in a fixed workshop. The butt welding machine includes the machine body and the hydraulic butt welding fixture.

[0043] Such as figure 1 As shown, the machine body is composed of left auxiliary rail mounting bolts, left auxiliary rail, left auxiliary rail, left main rail, left main rail, machine bed, electrical cabinet, welding controller, left induction heating transformer, and left main rail Mounting bolts, grinding wheel, transmission, grinding wheel motor, tool holder seat, operating handwheel, right main rail mounting bolts, right induction heating transformer, right main rail, right main rail, right auxiliary rail, right auxiliary rail, right auxiliary It is composed of rail mounting bolts and hydraulic cabinet.

[0044] The left auxiliary rail, the left main rail, the right main rail, and the right auxiliary rail have the same structure, and the cross-sectional shape is a "T" sub...

Embodiment 2

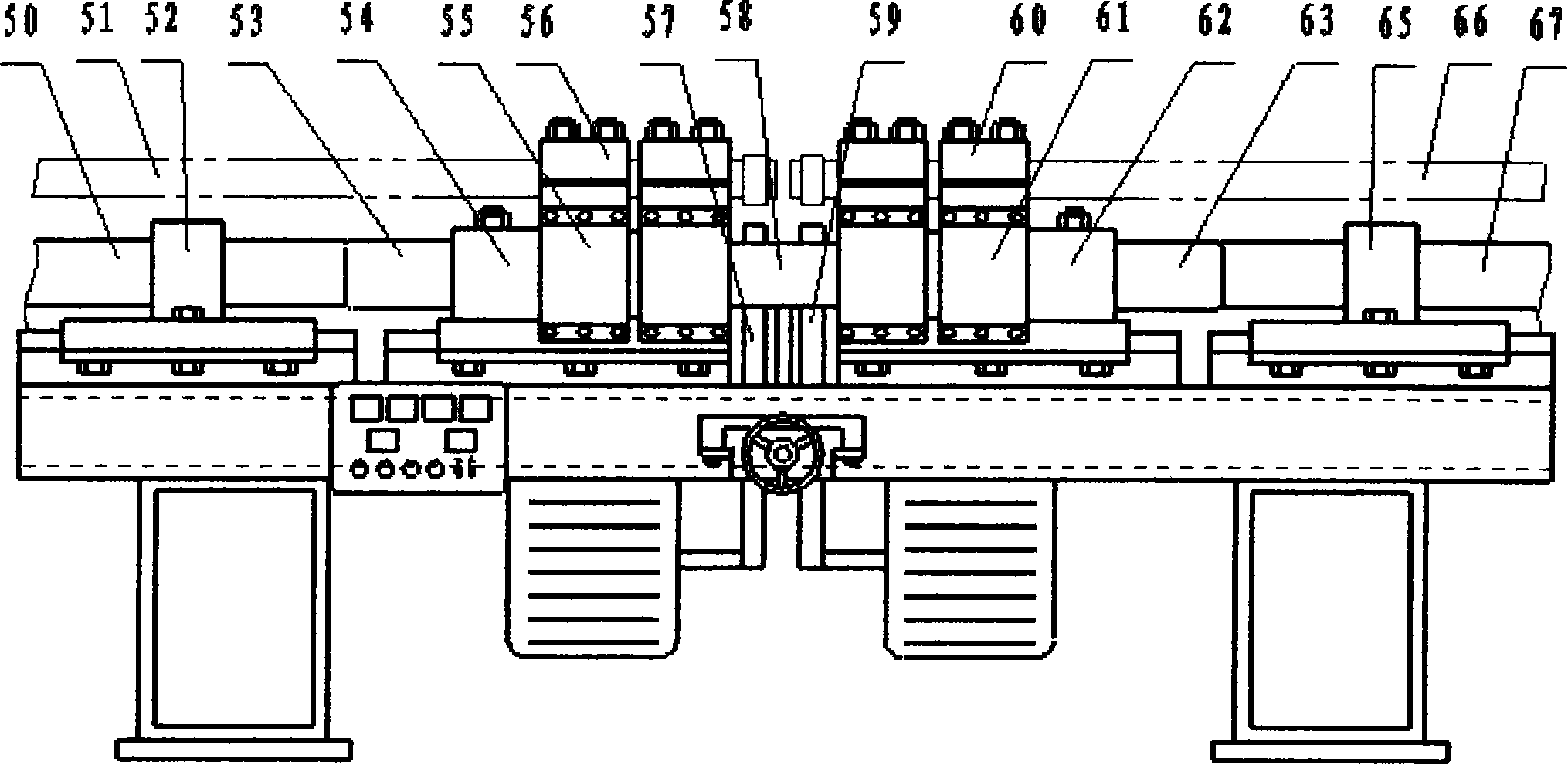

[0078] Carry out the butt welding of steel pipes, steel rails and round steel in the field construction site, using electric butt welding fixtures.

[0079] Such as Figure 4 As shown, the electric steel pipe butt welding fixture consists of the left torque motor, the left supporting wheel, the left torque motor fixing seat, the left arc connecting plate, the left induction heating transformer, the left induction heating coil, the connecting rod, the right induction heating coil, and the right arc. It is composed of connecting plate, right induction heating transformer, right torque motor fixing base, right supporting wheel and right torque motor.

[0080] The structure of the left supporting wheel, the left arc connecting plate, the left induction heating coil, the right induction heating coil, the right arc connecting plate, and the right supporting wheel of the electric steel pipe butt welding fixture are the same as the corresponding parts of the hydraulic steel pipe butt weldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com