Method of acid extracting aluminium from high-silicon alumina-containing raw mineral materials

A mineral raw material, high-silicon technology, applied in the field of aluminum extraction, can solve the problems of secondary pollution, residues and process wastewater containing fluorine, etc., and achieve the effect of less equipment corrosion, easy equipment materials, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

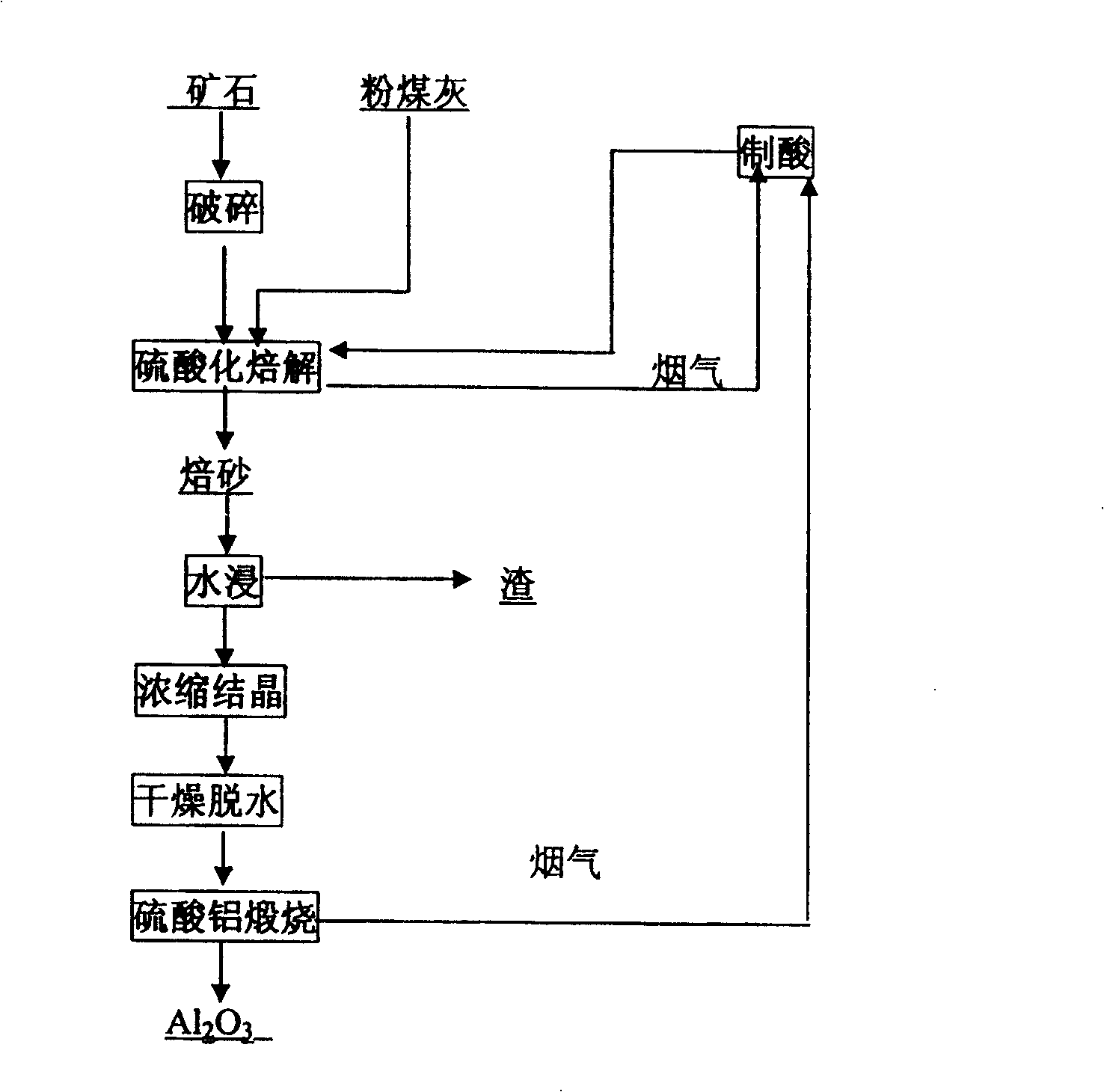

Image

Examples

Embodiment 1

[0039] The coal gangue containing 38% alumina and 48% silica is crushed, ground to -0.038mm and 98% sulfuric acid is mixed in a mass ratio of 1:1.5, and calcined in a furnace or kiln at 400°C for 2 hours. After leaching at 60°C for 60 minutes, the leaching liquid has a weight ratio of 5:1, and then filtering to obtain an aluminum sulfate solution. The leaching rate of aluminum oxide is 90.45%.

Embodiment 2

[0041] The coal gangue containing 38% alumina and 48% silica is ground to -0.25mm and mixed with 98% sulfuric acid in a mass ratio of 1:2, and roasted in a furnace and kiln at 300°C for 4 hours. The roasting material is heated at 90°C. After leaching for 120 minutes, the weight ratio of leaching liquid to solid is 5:1, and then filtering to obtain an aluminum sulfate solution. The leaching rate of aluminum oxide is 82.27%.

Embodiment 3

[0043] Mix unmilled fly ash with 41% alumina and 48% silica and 98% sulfuric acid in a mass ratio of 1:2, roast in a furnace and kiln at 350°C for 3 hours, and leaching the roasting material with water at 80°C After 90 minutes, the leaching liquid has a solid weight ratio of 3:1, and then filtered to obtain an aluminum sulfate solution. The leaching rate of aluminum oxide is 81.22%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com