Premixed charge compression ignition engine and reciprocating generator having the same

A compression ignition, premix technology, applied in the PCCI reciprocating generator, PCCI engine field, can solve the problem of increasing the compression ratio without explanation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Reference should now be made to the drawings, wherein like reference numerals are used to designate like or like components throughout the different drawings.

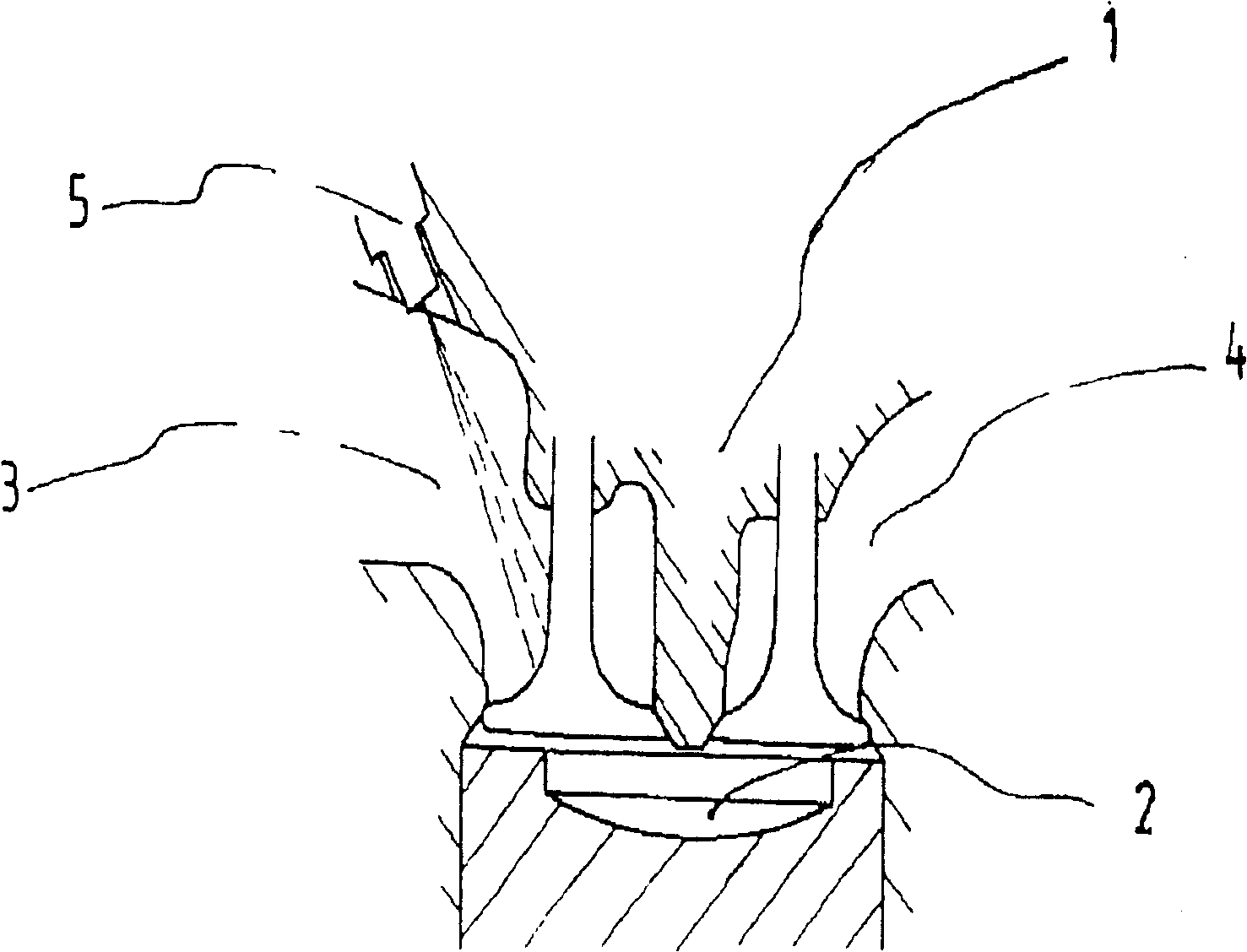

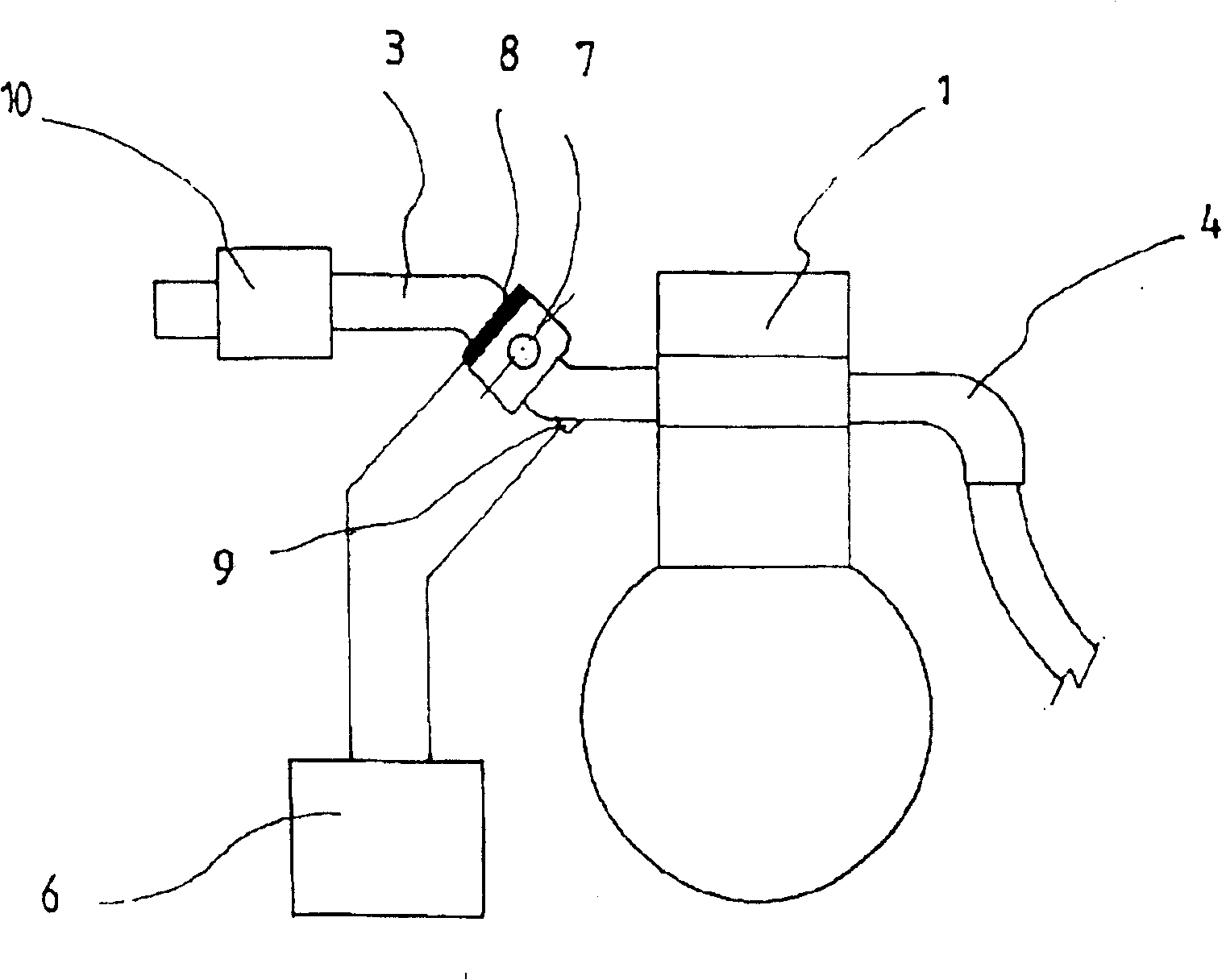

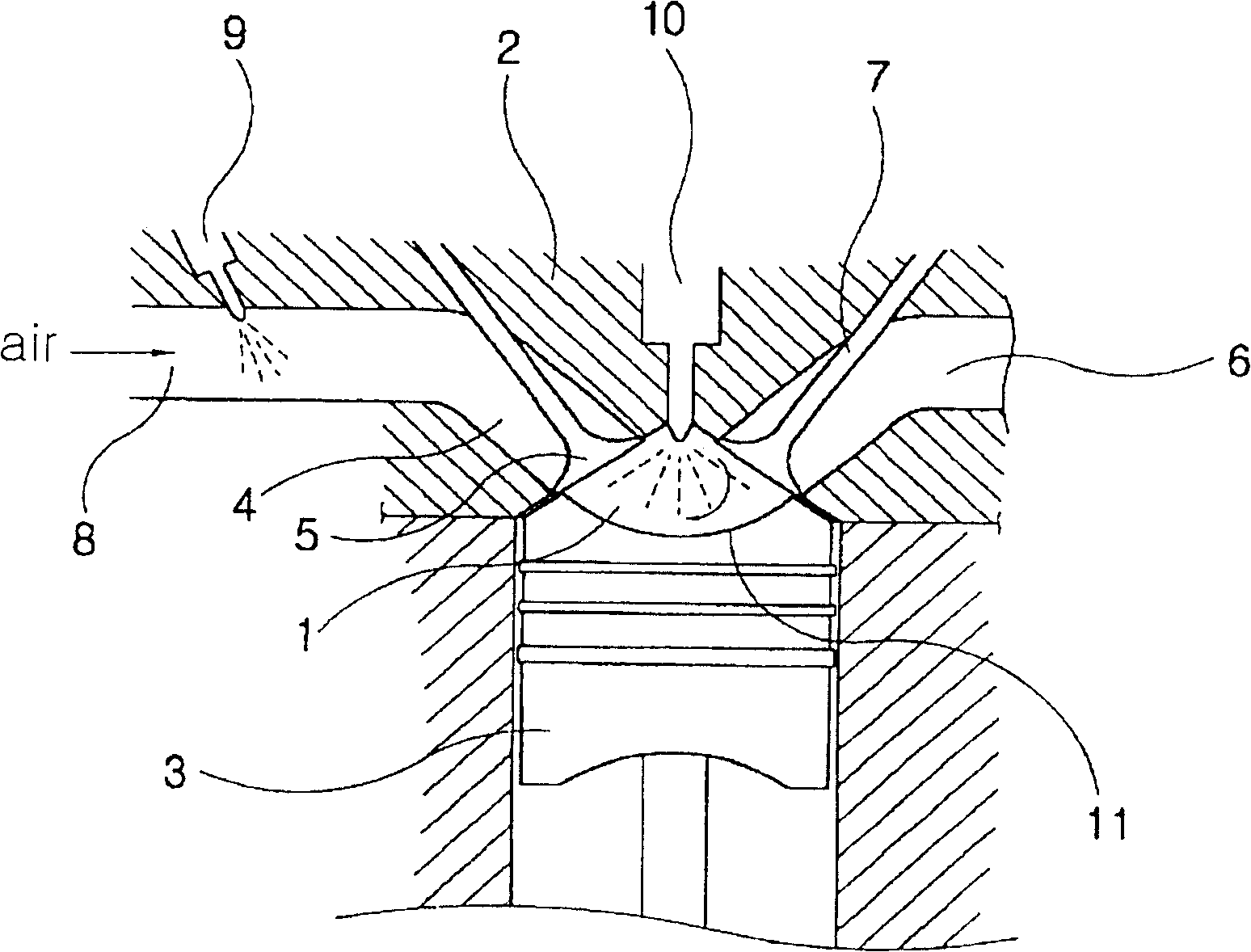

[0039] Figure 4 The cutaway diagram in demonstrates the operation of a conventional PCCI engine. Such as Figure 4 As shown, during operation of a conventional PCCI engine, intake air is introduced into the engine through intake manifold 8 . In intake manifold 8 , intake air is mixed with high-pressure fuel injected from injector 6 . Before the fuel is introduced into the combustion chamber 20, the fuel and air are mixed in the intake manifold 8, which is called "premixing" in the related art, and the premixed fuel and air in the above state are called "premixing". Premix".

[0040] When the inlet port 2 is open, the premix is introduced into the combustion chamber 20 . In the combustor 20, the premix is highly heated and compressed so that it has high temperature and pressure. When the piston 40 reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com