Test control unit of milling system of ball mill

A measurement and control device and a technology for machine-made flour, applied in the field of control, can solve the problems of inaccurate control, inconvenient control, and many measurement links, and achieve the effect of ensuring the quality of flour milling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with drawings and embodiments.

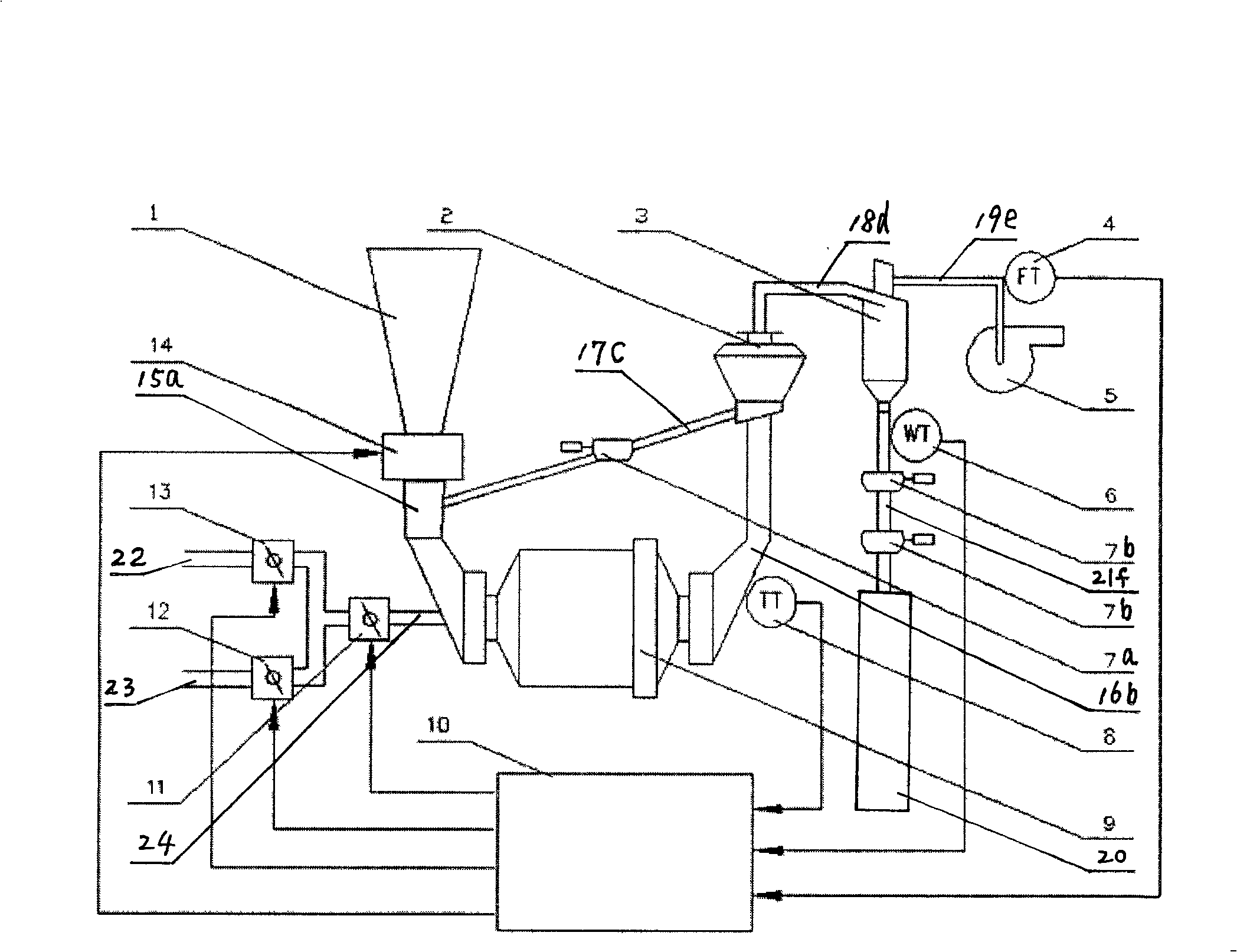

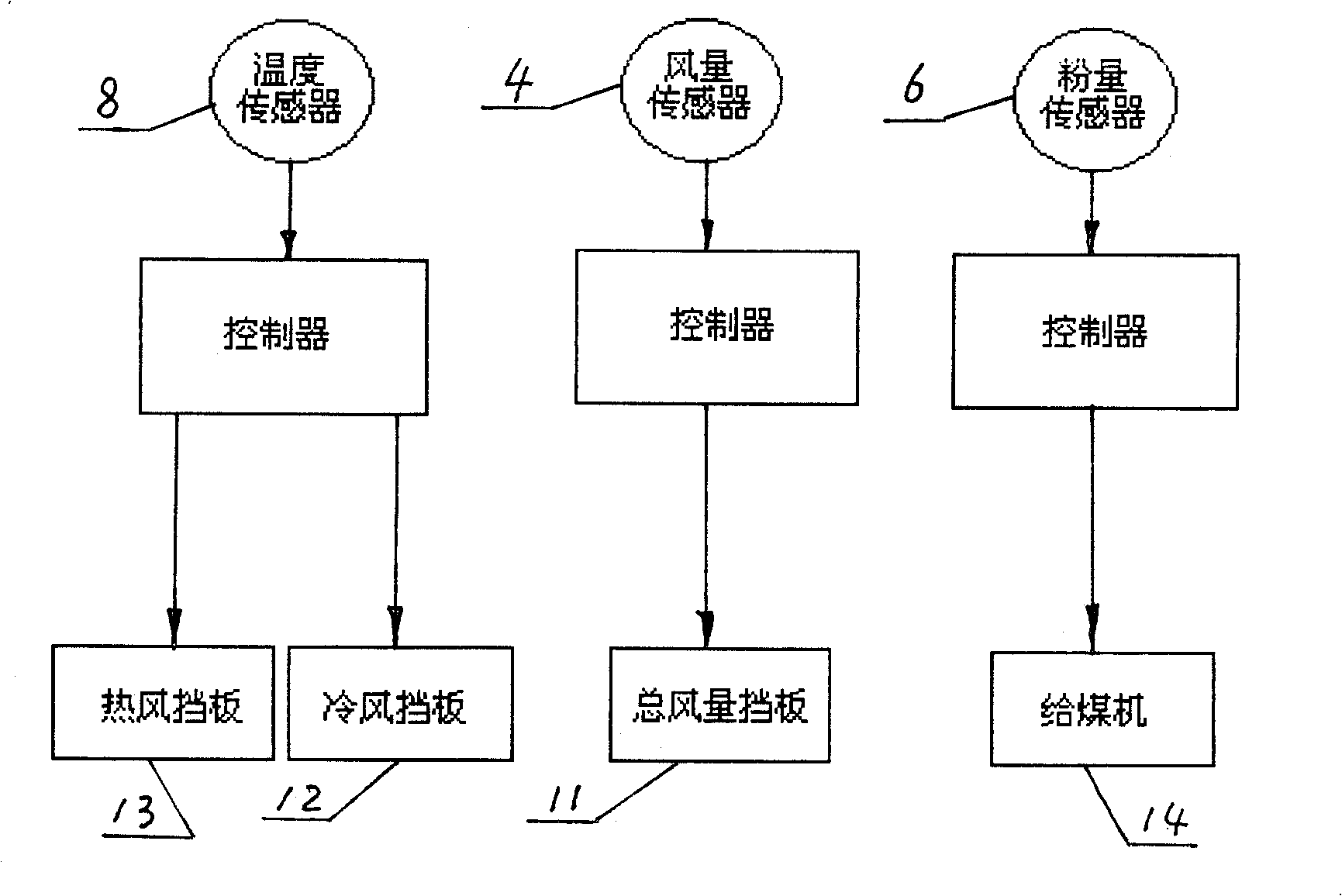

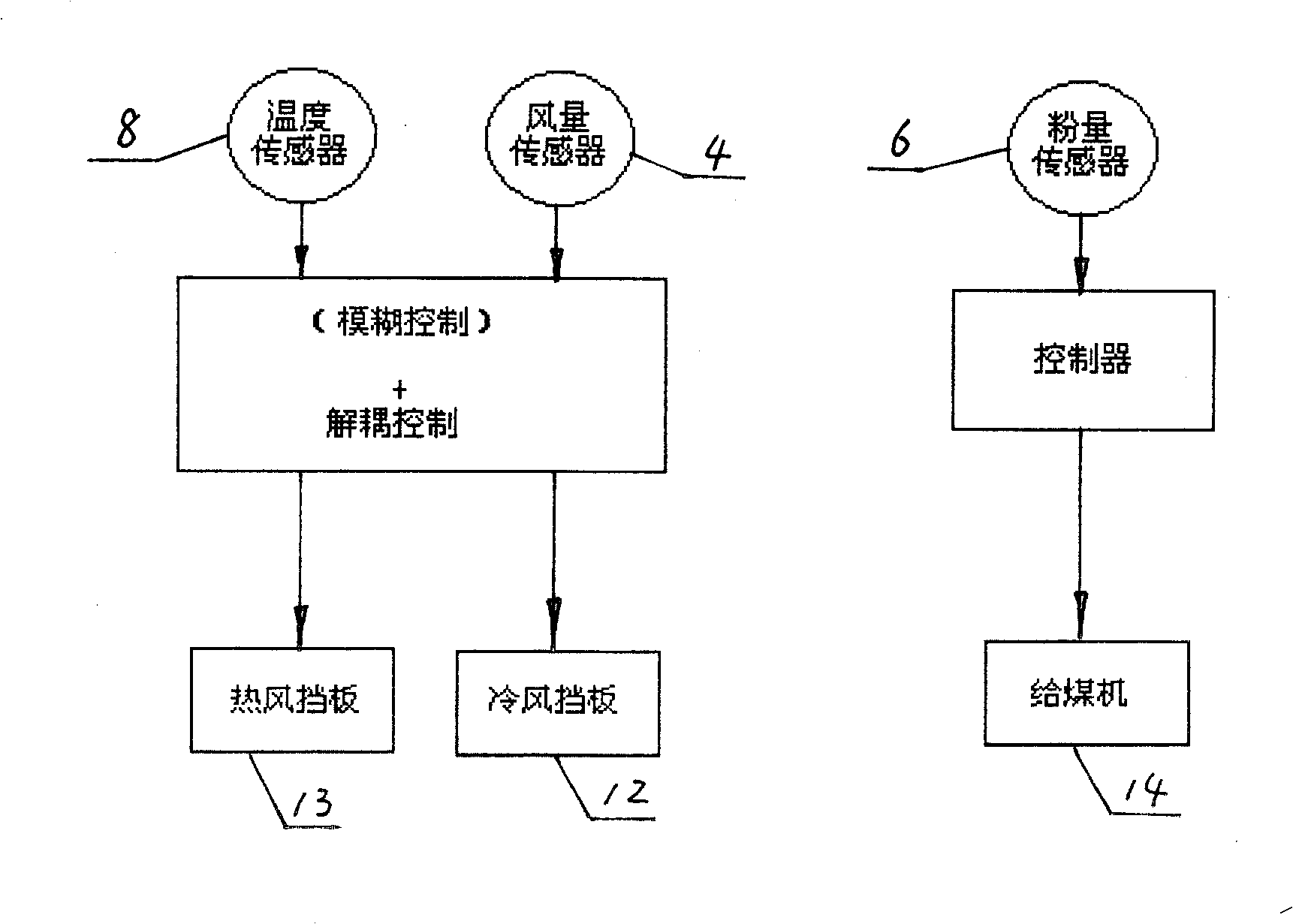

[0020] refer to figure 1 , the measurement and control device of the ball mill pulverization system of the present invention, it comprises the ball mill pulverization system, the ball mill pulverization system is connected with raw coal bunker 1 by coal feeder 14 inlets, coal feeder 14 outlets are connected with ball mill 9 inlets through pipeline 15a, cold 1. Hot air pipes 23, 22 are respectively connected with pipeline 15a through cold and hot air baffles 12, 13 arranged on respective pipelines; Plates 12, 13 are connected to the main air duct 24, the main air duct 24 is connected to the pipeline 15a through the installed total air volume baffle 11, the outlet of the ball mill 9 is connected to the inlet of the coarse powder separator 2 through the pipeline 16b, and the coarse powder separator 2 The unqualified coarse pulverized coal outlet is connected with the pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com