Medium grade insoluble sulphur preparing process and producing apparatus

A sulfur and soluble technology, applied in the field of preparation of medium-grade insoluble sulfur, can solve the problems of unstable product quality, high energy consumption, complicated operation, etc., and achieve the effect of high primary utilization rate, low energy consumption and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

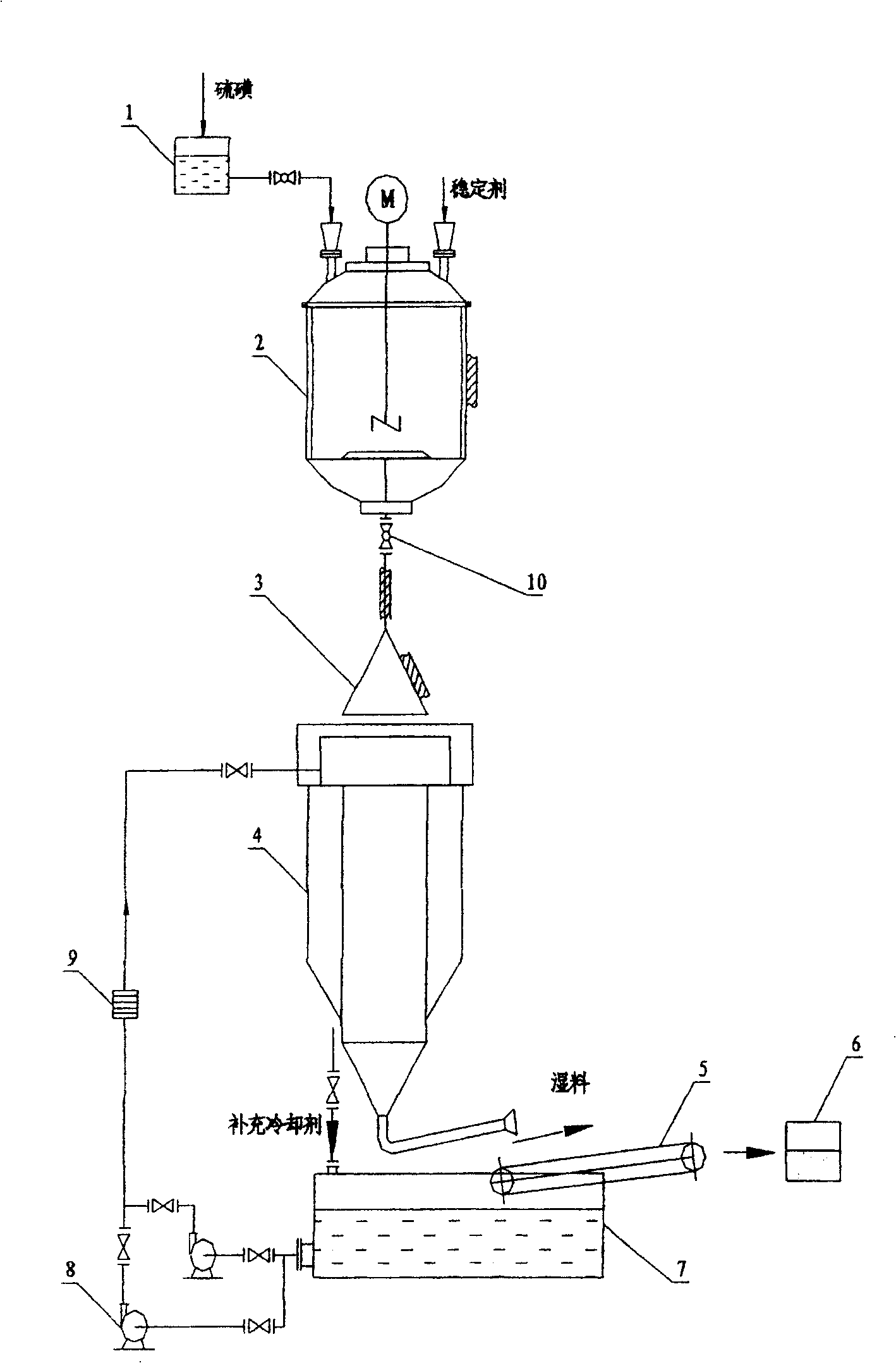

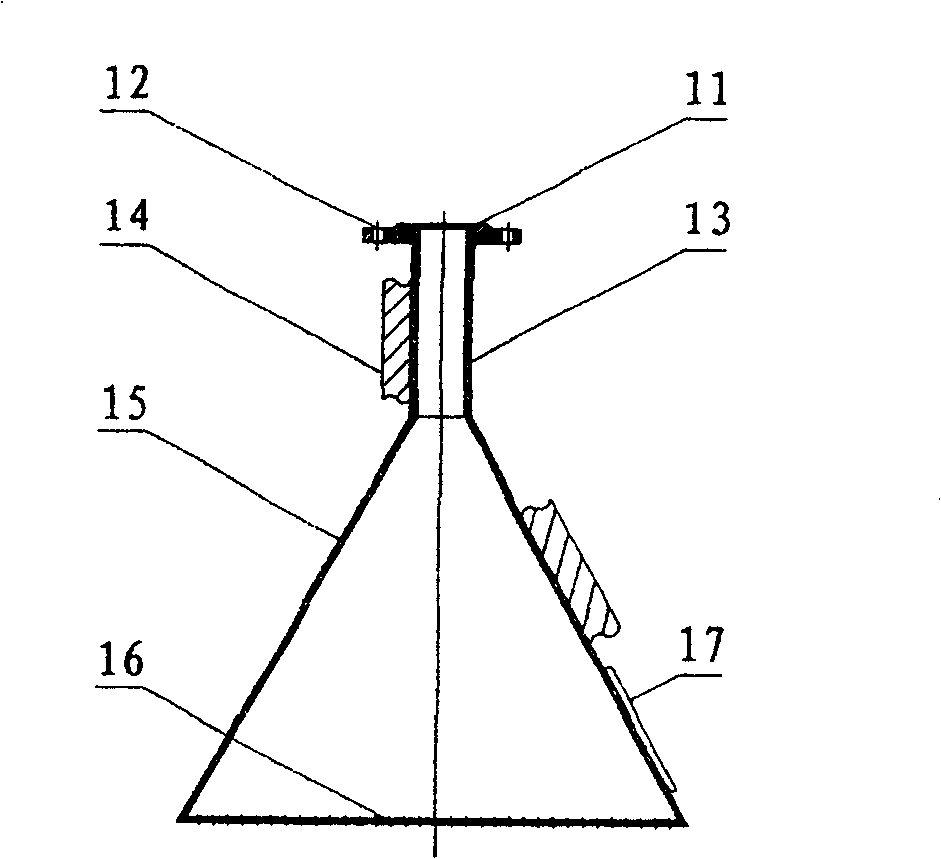

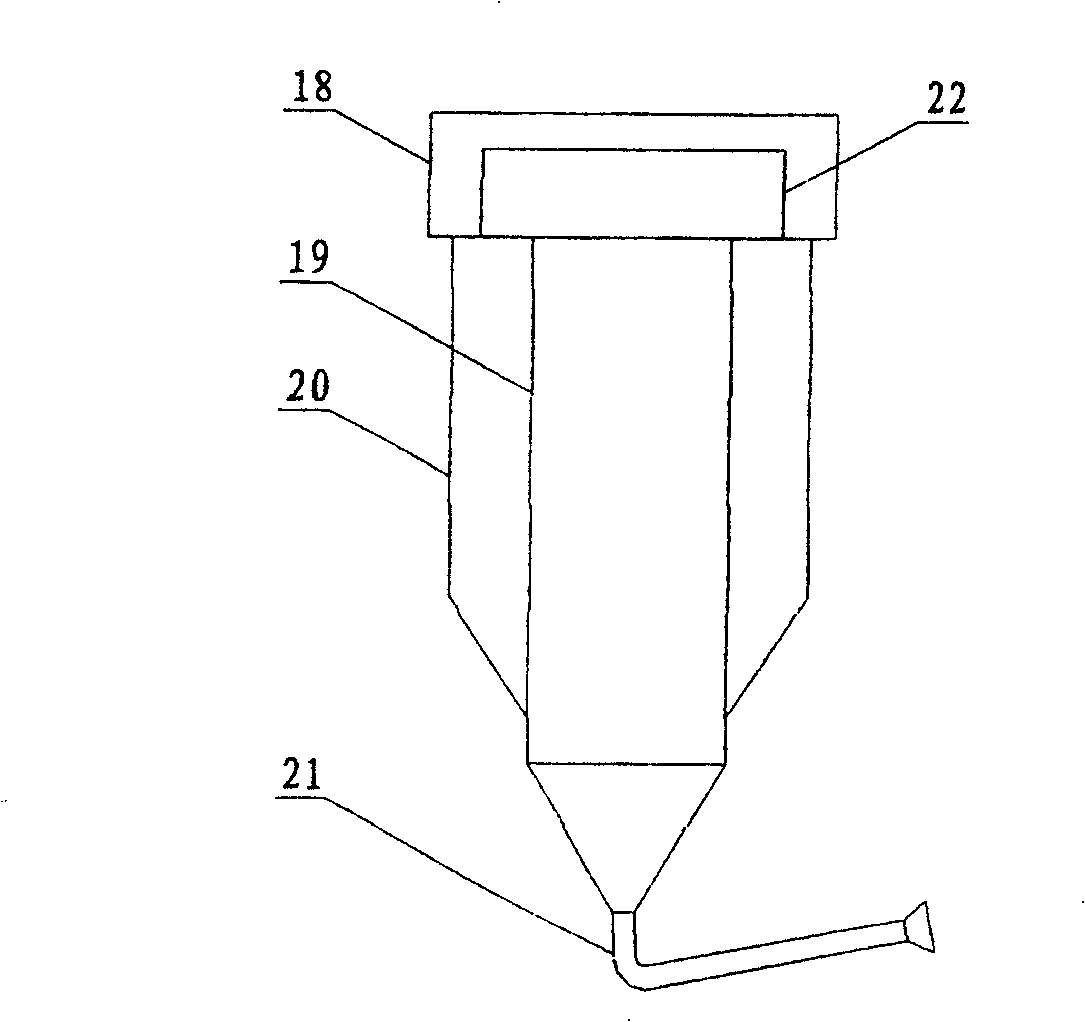

[0031] Pour 10,000 grams of 99.95% industrial high-grade sulfur into the high-level sulfur melting tank (1) to melt it into liquid sulfur. The temperature is controlled below 150°C. At this temperature, the viscosity of liquid sulfur is very small. and 0.5 g I 2, and 7.5 grams of DM were added together into the reaction kettle (2) with stirring, heating and temperature control systems, until the temperature of the sulfur melt reached 280° C., and kept constant for 1 hour. The molten sulfur flows into the orifice device (3) through the insulated discharge valve (10), and the flow rate is controlled at 1kg / min, so that the liquid sulfur passes through the orifice (6) evenly and stably. The liquid sulfur flowing out from the orifice plate (6) enters the quenching tower (4) and is fully contacted with the coolant to be rapidly cooled into an elastic transparent body, and the elastic transparent body falls on the belt conveyor (5) with the coolant and is sent to the oven (6) ) at ...

Embodiment approach 2

[0033] Pour 10,000 grams of 99.95% industrial high-grade sulfur into the high-level sulfur melting tank (1) to melt it into liquid sulfur. The temperature is controlled below 150°C. At this temperature, the viscosity of liquid sulfur is very small. and 0.5 g CH 2 = CHCl, 7.5 grams of DZ were added together into the reactor (2) with a stirring, heating and temperature control system, until the temperature of the sulfur melt reached 290°C, and kept constant for 1 hour. The molten sulfur flows into the orifice device (3) through the insulated discharge valve (10), and the flow rate is controlled at 0.8kg / min, so that the liquid sulfur passes through the orifice (6) evenly and stably. The liquid sulfur flowing out from the orifice plate (6) enters the quenching tower (4) and is fully contacted with the coolant to be rapidly cooled into an elastic transparent body, and the elastic transparent body falls on the belt conveyor (5) with the coolant and is sent to the oven (6) ), dryin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap