Reclaimed concrete aggregate two-ash broken stones

A technology of recycled concrete and ash stone, which is applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of land occupation, ecological destruction, waste of resources, etc., and achieve unconfined compressive strength improvement, Conducive to the protection of the ecological environment and the effect of improving the compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] First, waste concrete recycled aggregates are produced by the following process.

[0023] 1. Discarded concrete components or blocks in construction waste, broken concrete engineering pile superfill pile heads or foundation pit horizontal support beams and various concrete test blocks are classified and collected.

[0024] 2. Break the recovered concrete components or blocks once (it can be broken manually or mechanically), and take out the steel bars, embedded parts and other metal objects that may be contained in them. The size of the primary crushed block is determined according to the needs of the secondary crushing machinery.

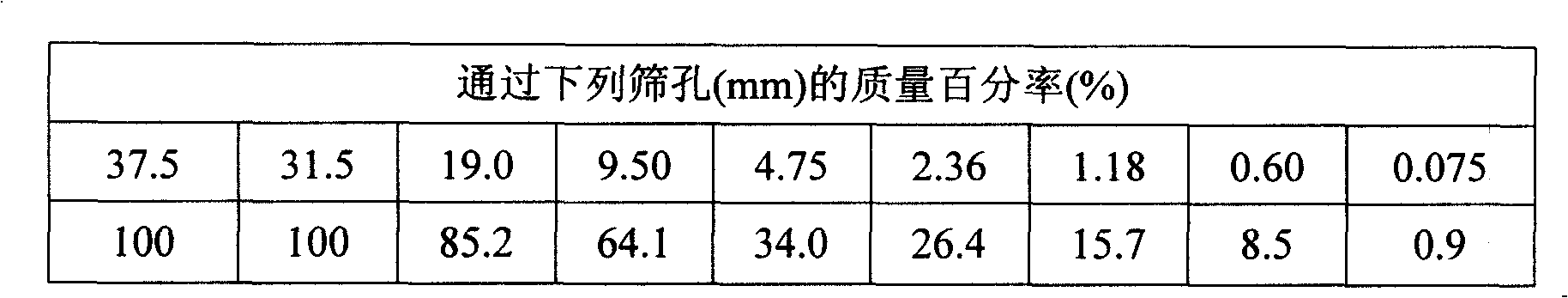

[0025] 3. Secondary crushing of the concrete blocks after primary crushing by corresponding shaped crushing machinery, and sieving to obtain concrete recycled aggregates with required particle size gradation. The specific particle gradation is shown in the following table:

[0026]

[0027] The obtained waste concrete regenerated aggrega...

Embodiment 2

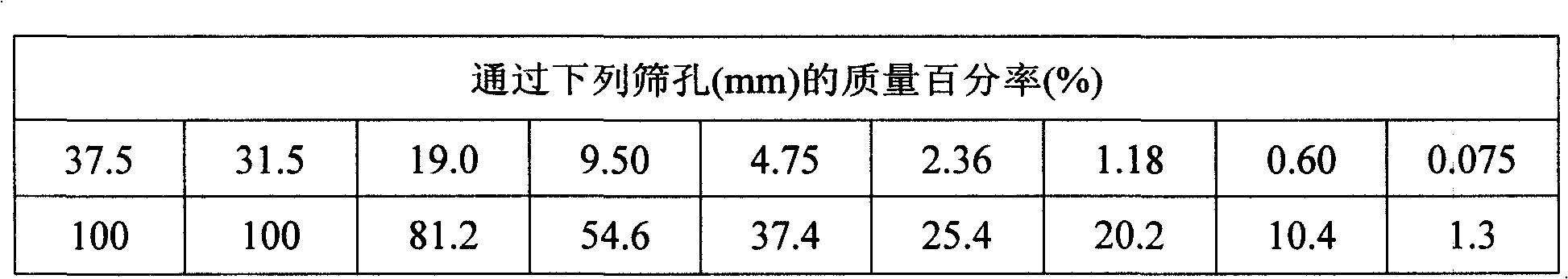

[0034] First, waste concrete recycled aggregates were produced according to the process described in Example 1 to obtain concrete recycled aggregates with the required particle size distribution. The specific particle size distribution is shown in the following table:

[0035]

[0036] The saturated surface dry water absorption of waste concrete recycled aggregate is 4.2%, the crushing value is 24.2%, and the apparent density is 2.69g / cm 3 .

[0037] The above waste concrete regenerated aggregate was mixed in a mass ratio of 37.4% of stone chips and rice sand, 17% of melon seed slices, 27% of small crushed and 18.6% of medium crushed.

[0038] Then, adopt the same slaked lime and fly ash as in Example 1, and make the recycled concrete aggregate fly ash concretion of the present invention by the ratio of lime: fly ash: waste concrete recycled aggregate=6:12:82. The fly ash stone specimens were prepared by the maximum dry density and optimum water content determined by the c...

Embodiment 3

[0040] First, the waste concrete regenerated aggregate, slaked lime and fly ash same as those in Example 2 were used.

[0041] Second, press Na 2 SO 4 Na 2 CO 3 Each 50% mass ratio is used to prepare special admixtures.

[0042] Then, mix according to the ratio of lime: fly ash: waste concrete recycled aggregate = 6: 12: 82: 2, and add special admixture according to 2% of the sum of the quality of the aforementioned lime and fly ash to obtain this product The recycled concrete aggregate fly ash calculus described in the invention. The fly ash stone specimens were prepared by the maximum dry density and optimum water content determined by the compaction test, and the unconfined compressive strengths obtained at 7d and 28d ages were 2.20 and 4.86Mpa, respectively.

[0043] It can be seen that the special admixture of recycled concrete aggregate fly ash and stone has a significant effect on improving the unconfined compressive strength, and the unconfined compressive strengt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com