High furnace infrared thermoviewer protecting device

A technology of infrared thermal imaging camera and protective device, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of weak dustproof ability, affecting normal production, and unsafety of blast furnace infrared thermal imaging camera protective device, so as to ensure long-term Effective operation, automatic cleaning, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

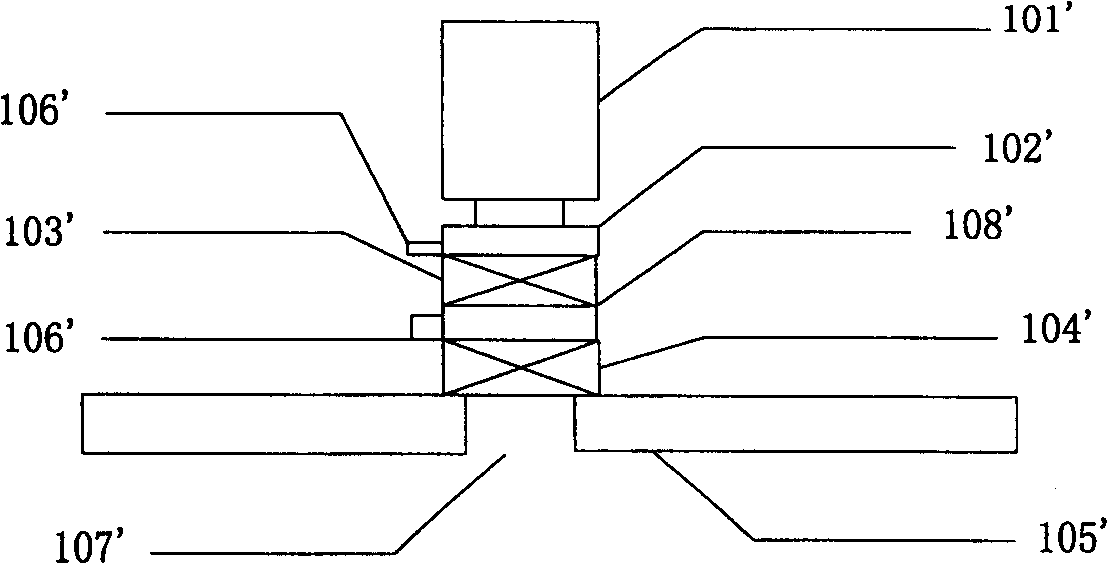

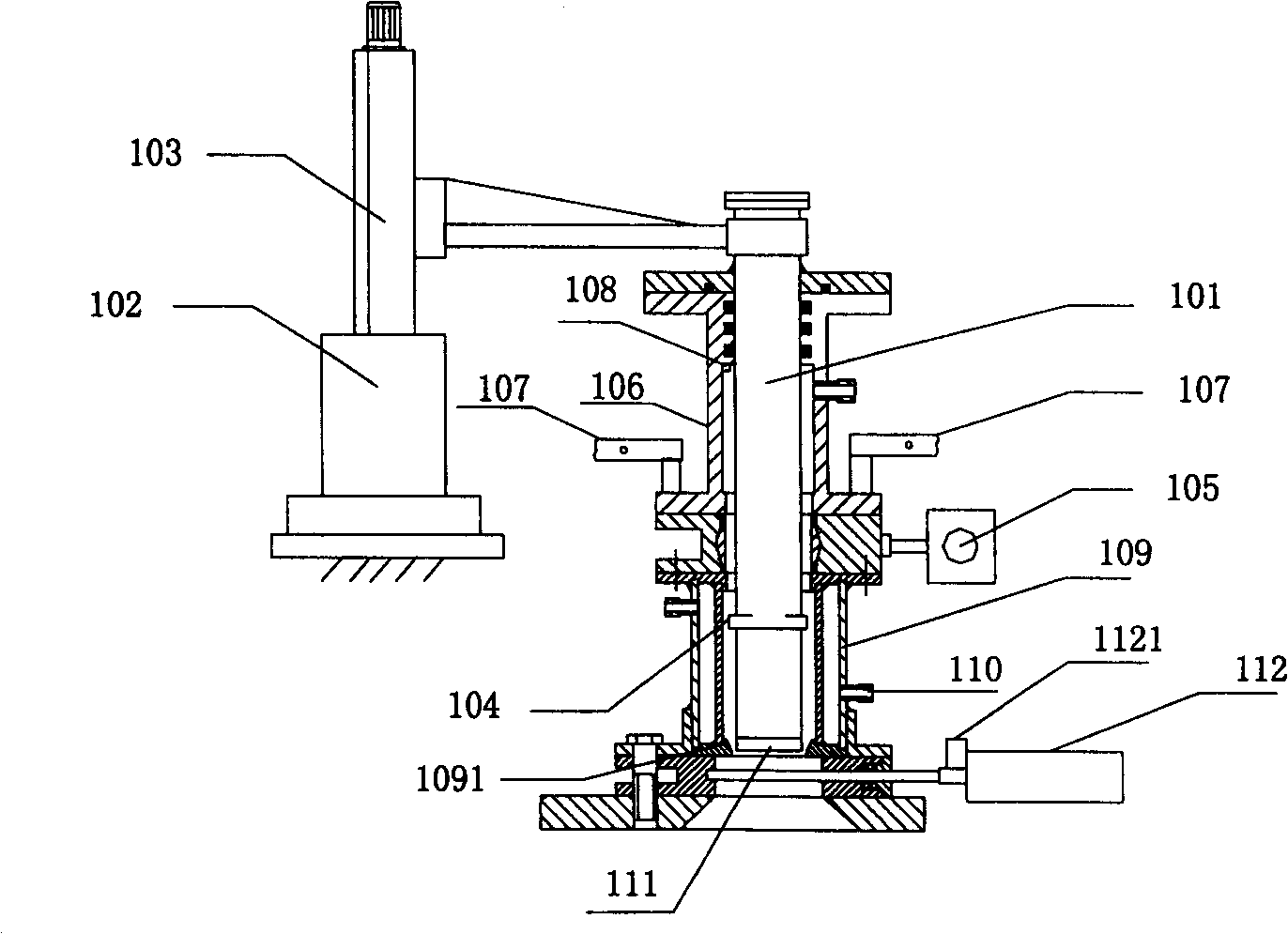

[0022] According to the following figure 2 , a preferred embodiment of the present invention is described.

[0023] like figure 2 As shown, it is a schematic structural diagram of a blast furnace infrared thermal imager protection device provided by the present invention, which includes a thermal imager advancing and retreating device, an electric ball valve sealing device, an airflow protection device and a straight plate valve cleaning device;

[0024] The thermal imager advancing and retreating device includes a thermal imager probe 101, an electric rotating device 102 and a probe advancing and retreating device 103; a thermal imager and a lens are installed inside the thermal imager probe, and the thermal imager probe is a closed device , fill the interior with dry and clean gas to ensure that the environment where the thermal imager and the lens are located is clean and will not cause damage to them; further, a positioning pin 104 is provided on the outer side of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com