Cotton seed dephenolizing protein complete equipment

A technology of dephenolized protein and complete equipment, which is applied in the direction of plant protein processing, fat production, animal feed, etc., can solve the problems of reducing protein utilization rate in cottonseed, destroying protein structure, difficult process control, etc., to reduce the amount of special equipment, Broad source, effects of addressing variability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

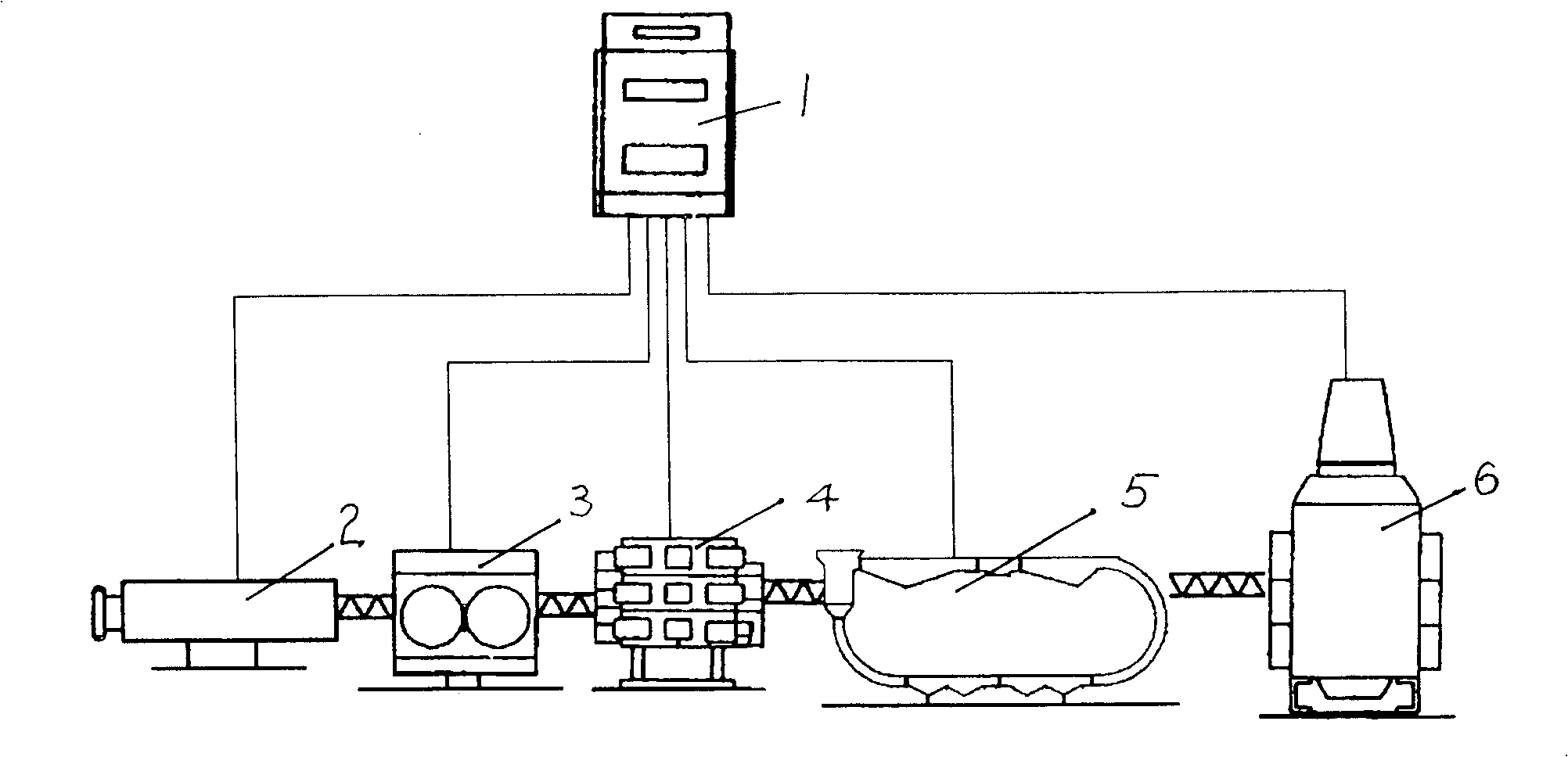

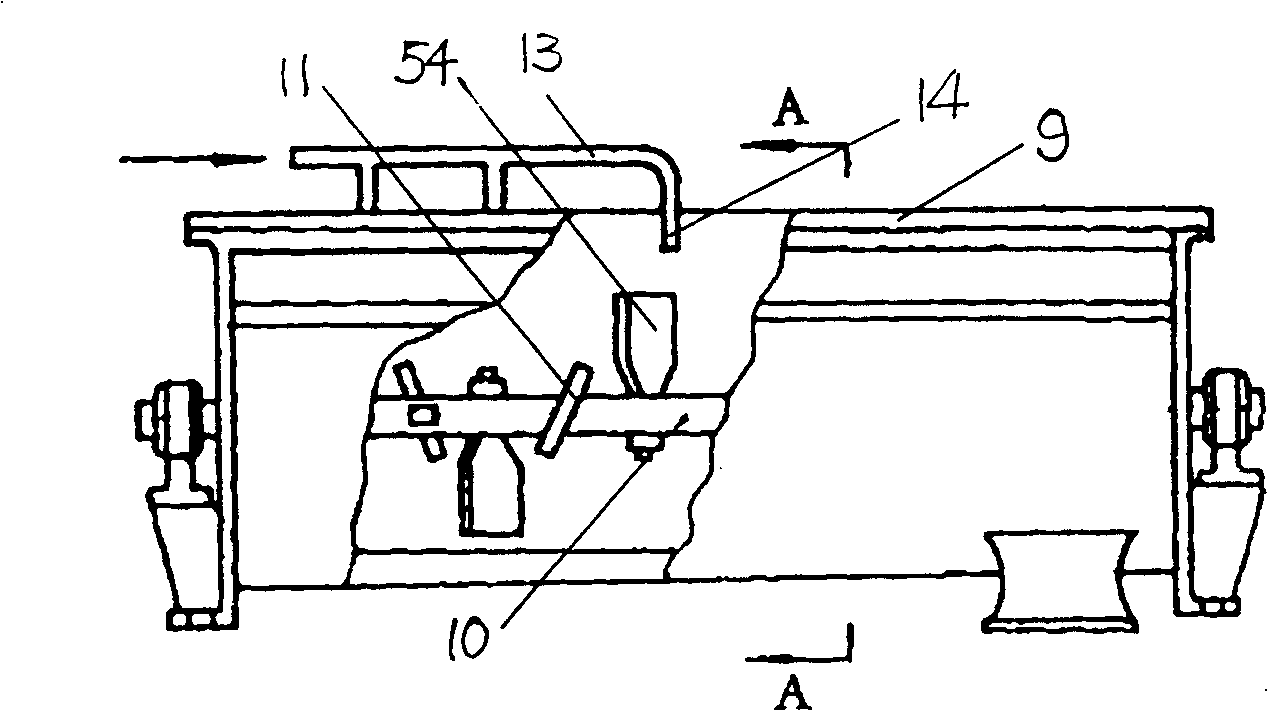

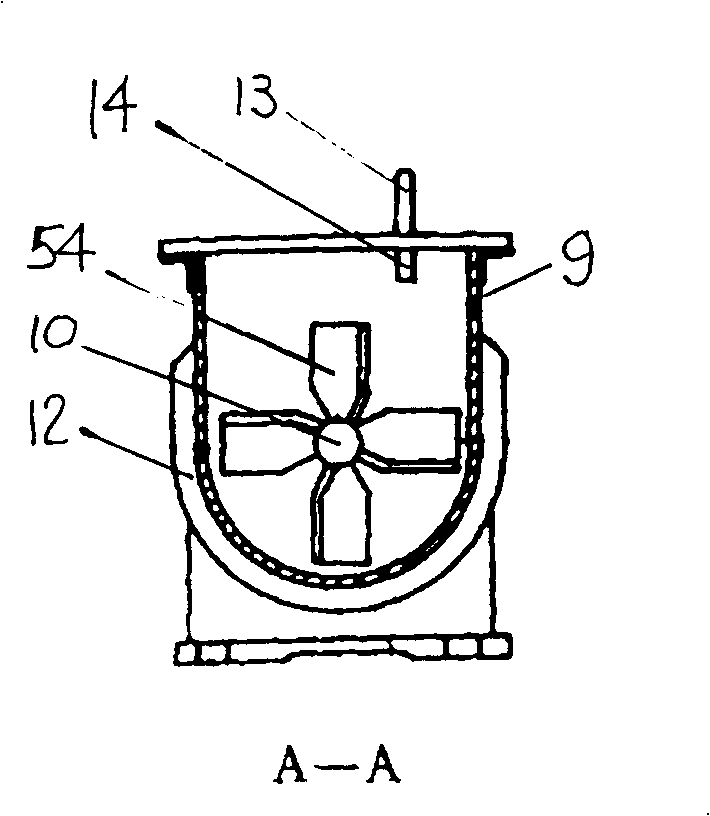

[0015] The specific embodiment of the present invention is as follows: including electric control device 1, softening device 2, pressing device 3, drying device 4, leaching device 5 and extracting device 6 and corresponding steam generator, the key is softening device 2, pressing device The device 3, the drying device 4, the leaching device 5 and the extraction device 6 are connected sequentially, each of the above devices is connected to the electric control device 1 and a feeding device 8 is arranged between each device; the electric control device 1 is controlled by a computer The main engine and the control devices of the above-mentioned devices are all connected to them via data lines. The computer can regulate the operation of each device to make the whole set of equipment work in harmony. Since the steam generator and the corresponding steam delivery pipeline are existing technologies, the manual does not describe in detail. The figure is also not shown.

[0016] Descri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com