Dynamic filter module

A kind of filter body, dynamic technology, applied in the direction of filtration and separation, fixed filter element filter, water/sludge/sewage treatment, etc., can solve the problem of shortening the cycle of dynamic filter layer peeling and regeneration, and achieve stable filtered water volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

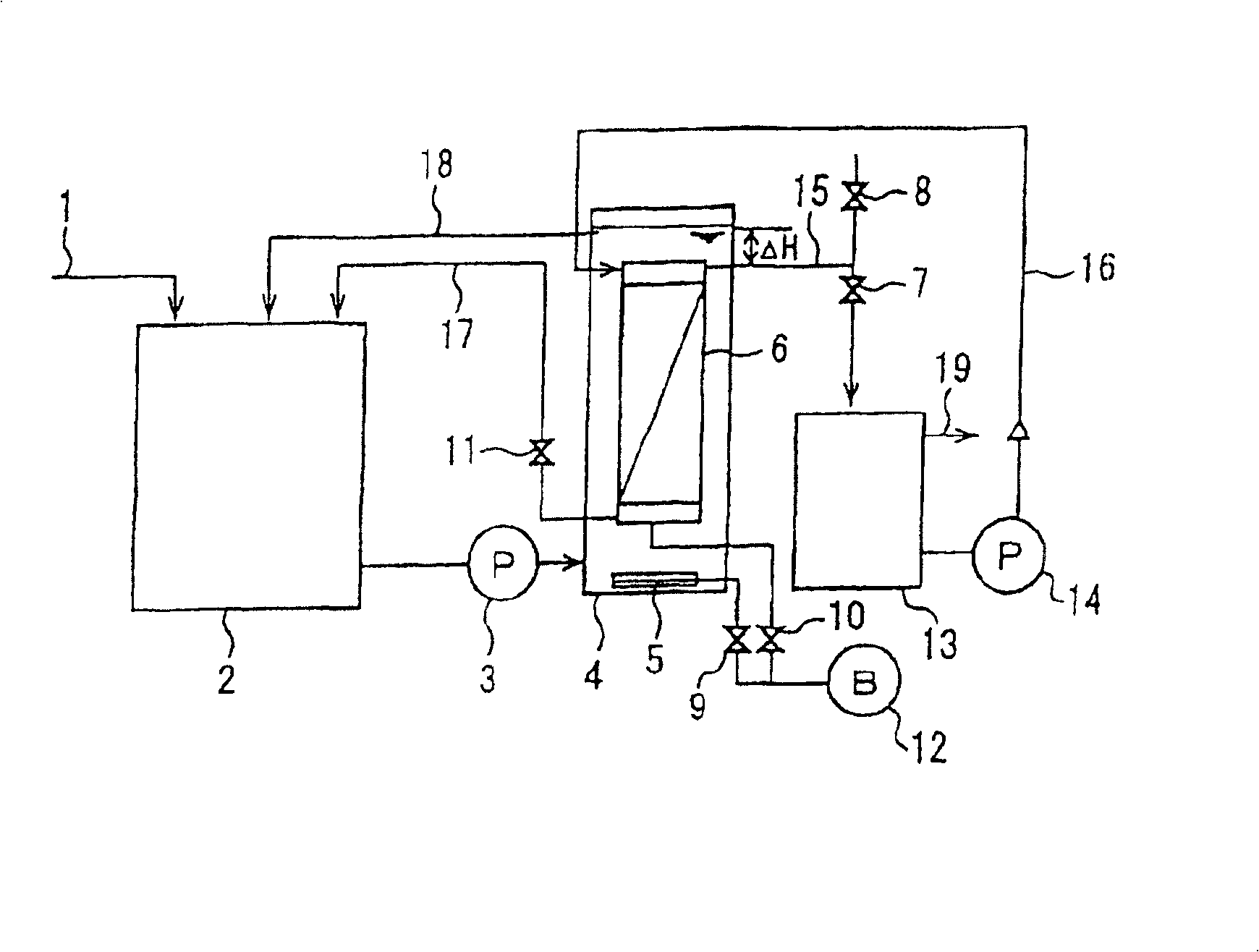

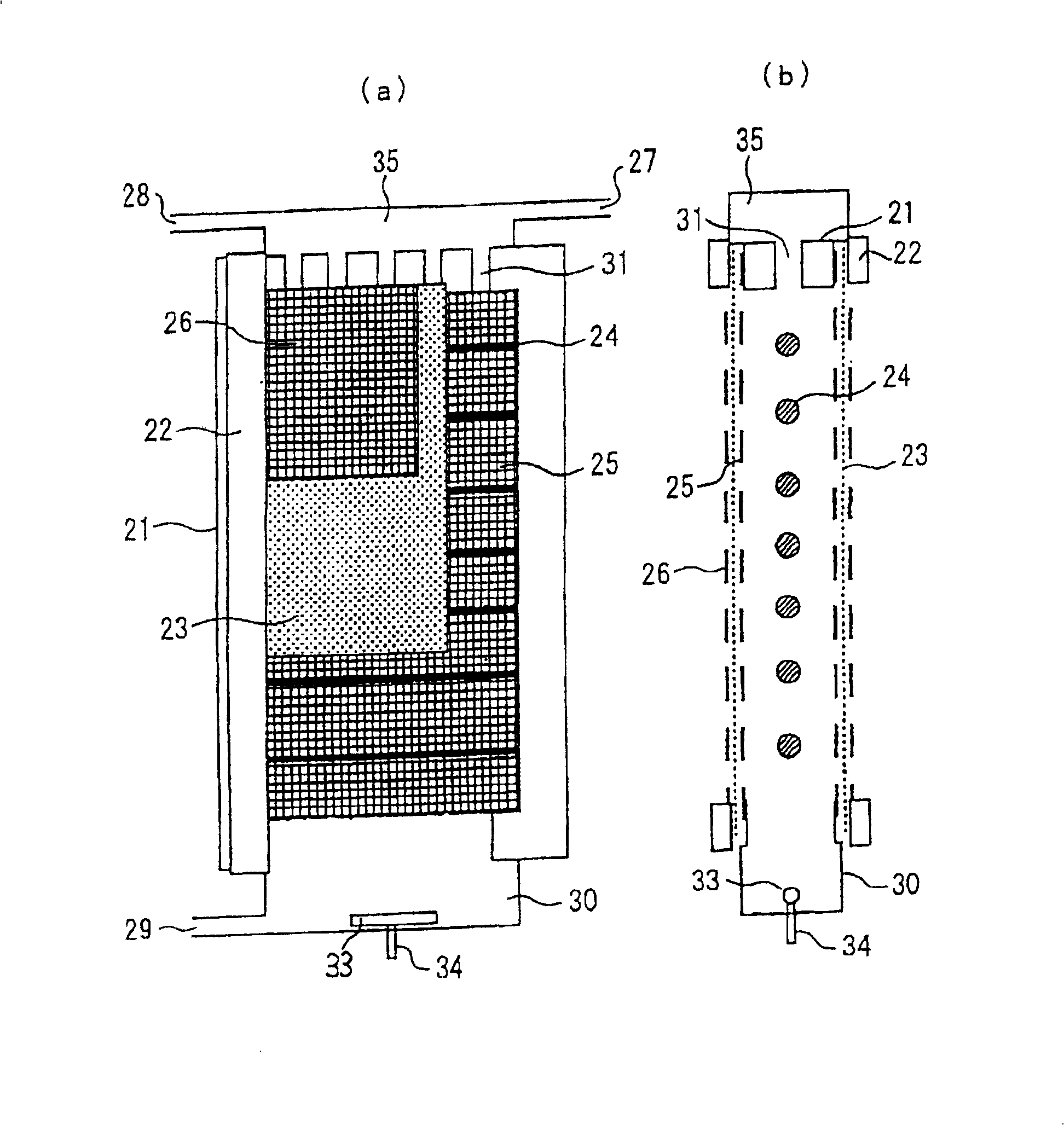

[0059] use figure 2 The dynamic filter body module shown, for the figure 1 The activated sludge mixture obtained in the activated sludge treatment system for residential drainage is subjected to solid-liquid separation treatment.

[0060] As a support material for forming the dynamic filter layer, a polyester woven cloth with a thickness of about 0.1 mm and a pore diameter of 114 μm sandwiched between two polyethylene meshes with a mesh size of 10 mm and a thickness of 2.0 mm was used. 5 effective areas of 1m 2 Each piece of planar filter body module is immersed and arranged in the filter separation tank. The water level difference during filtration is about 10 cm, and the cross flow velocity of the sludge mixture on the surface of the filter body is 0.025 m / s on average.

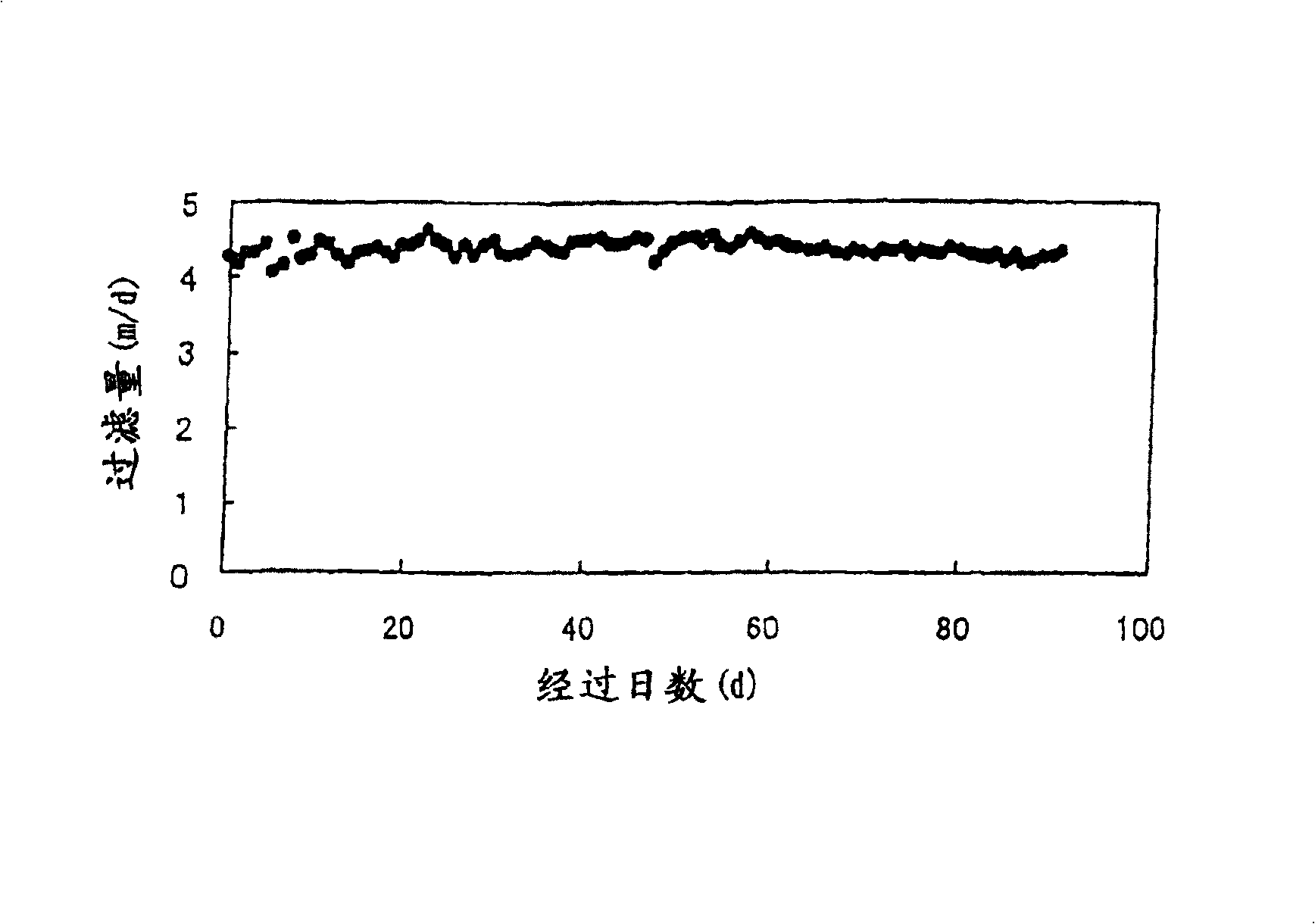

[0061] Every 2 hours of filtration operation, the cleaning operation of air cleaning outside the filter body-air cleaning inside the filter body-water cleaning inside the filter body and mud discharge i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com