Water-saving environment friendly industrialized treatment system and method for cleaning beans

A processing system and bean technology, applied in chemical instruments and methods, climate change adaptation, solid separation, etc., can solve the problems of polluting the environment, consuming a lot of water, etc., achieving the effects of small investment, avoiding waste, and increasing the emergence rate of seedlings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

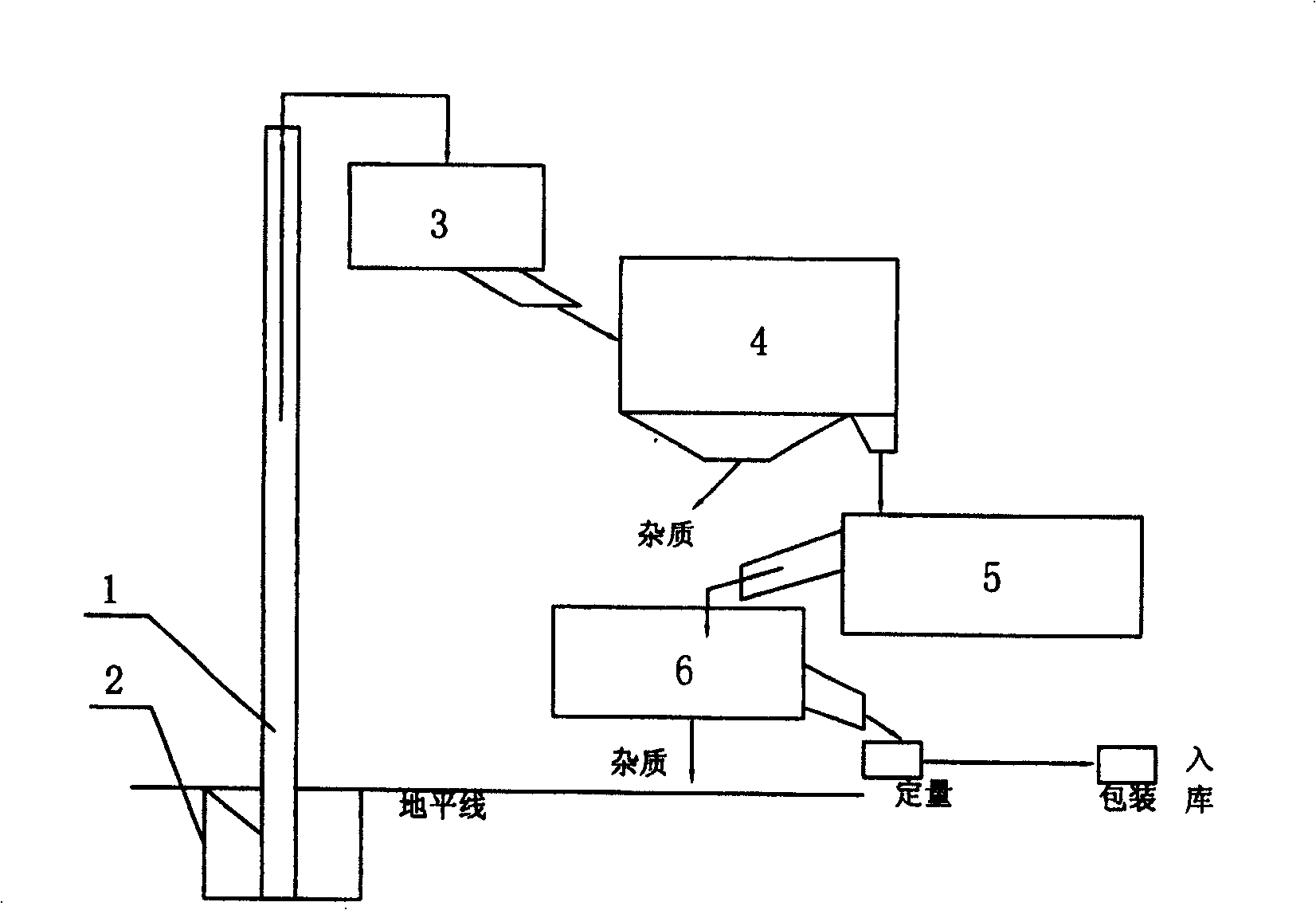

[0026] figure 1 , The bucket elevator 1 is installed on the ground, and a hopper 2 is arranged on it to lift the beans to the upper part. The bucket elevator 1 lifts the beans and sends them into the bean storage trough 3. The outlet of the bean storage trough 3 is connected to the cyclone multi-layer cylindrical screen 4 through a pipeline. The type of the cyclone multi-layer cylindrical screen is TFXH. There are many types of cylindrical sieves, which can be replaced with corresponding cylindrical sieves according to the beans used. There are permanent magnets in the sieves, which can remove the iron impurities in the beans first, and at the same time pass through the large and small sieves during the rolling process. Medium and large impurities are removed, such as: bean shells, grass knots, soil particles, masonry debris and other sundries, and the beans are sent to the next process. The impurities are discharged from the discharge port, and the beans are sent to the flat...

Embodiment 2

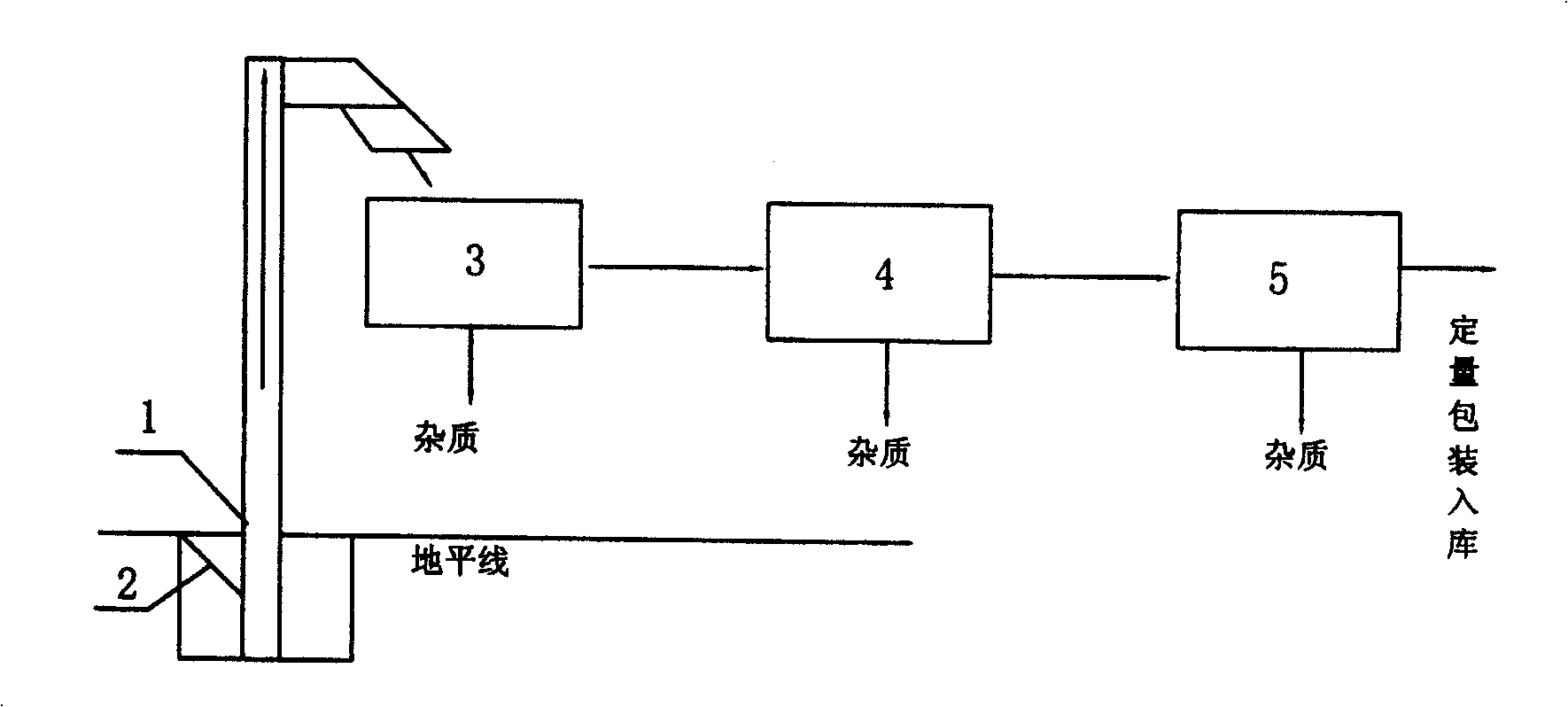

[0028] figure 2 , in this embodiment, the whole system is the same as that of Embodiment 1, except that the bean storage tank 3 is on the upper part of the bucket elevator 1, the cyclone multi-layer cylindrical screen 4 is below the bean storage tank 3, and the flat shock multi-layer flotation screen 5. The horizontal positions of the surface fine washing machine 6 and the cyclone multi-layer cylindrical screen 4 are arranged in sequence.

[0029] Implementation three:

[0030] Taking the processing of 10 tons of soybeans as an example, first send 10 tons of soybeans into the hopper of the bucket elevator 1, and the soybeans are sent from the hopper 2 of the bucket elevator 1 into the bean storage tank 3, and the gate of the bean storage tank 3 controls the soybeans The flow rate is sent to the cyclone multi-layer cylindrical sieve 4, the flat shock multi-layer flotation screen 5 whose screen mesh matches the soybean, and the multi-layer cylindrical sieve with permanent magn...

Embodiment 4

[0032] When processing 10 tons of mung beans, the sieve mesh level vibration flotation screen 5 of the cyclone multi-layer cylindrical sieve 4 can be replaced with the sieve mesh matching the mung beans, and the rest of the steps are the same as in the third embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com