Small plant oil and fat refining device and method

A vegetable oil and refining device technology, applied in the direction of oil/fat refining, fat production, etc., can solve the problems of perishable, heat-sensitive substances, toxins and harmful substances cannot be removed, oil safety problems, etc. Flexible, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

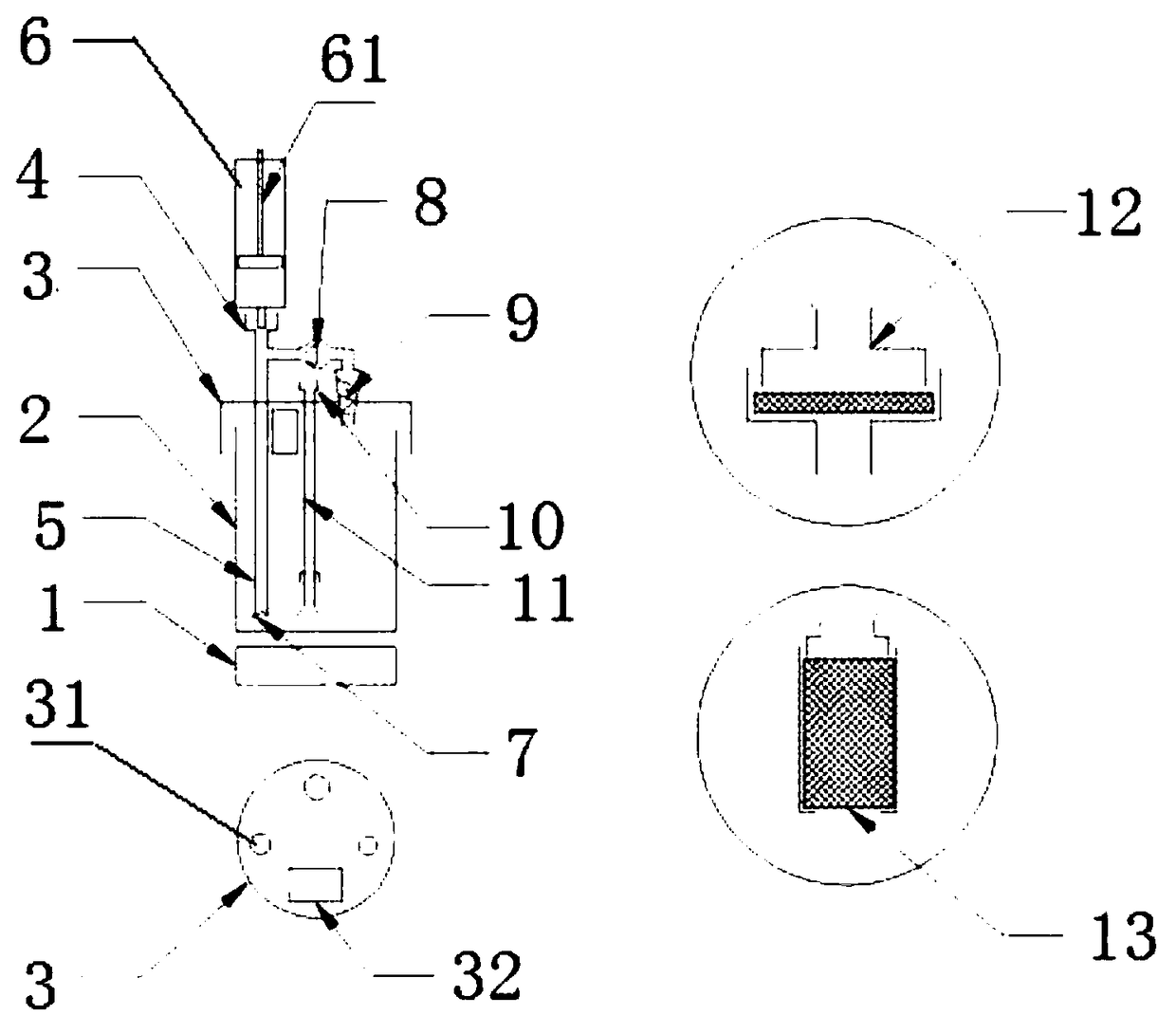

[0021] A small vegetable oil refining device, including a heating plate 1, a container 2, an upper cover 3, a first connection port 4, a circulation pipe 5, a sampler 6, a first one-way valve 7, a second one-way valve 8, a mixing device 9, the second connection port 10, the inlet and outlet pipe 11, the filter head 12, and the decolorization column 13; There are three round holes 31 and a desiccant storage tank 32 on the upper cover. The circulation pipe 5 passes through one of the round holes on the upper cover 3 into the container. The upper end of the circulation pipe 5 is provided with a first connection port 4, and the pipe The first one-way valve 7 is provided on the road; a branch pipe is also provided on the top of the circulation pipe 5, and the other end of the branch pipe is connected to the mixer 9, and the mixer 9 communicates with the container 2 from the second round hole; the branch pipe The pipeline is provided with a second one-way valve 8; the inlet and outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com