Heavy-oil-burning grain-drying complete apparatus

A technology of grain drying and complete equipment, which is applied in the direction of drying solid materials, lighting and heating equipment, heating to dry solid materials, etc. It can solve the problems of grain stagnation and regeneration, large temperature fluctuations, high costs, etc., and achieve the reduction of regeneration rate, Good antifreeze performance and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in detail below in conjunction with accompanying drawing:

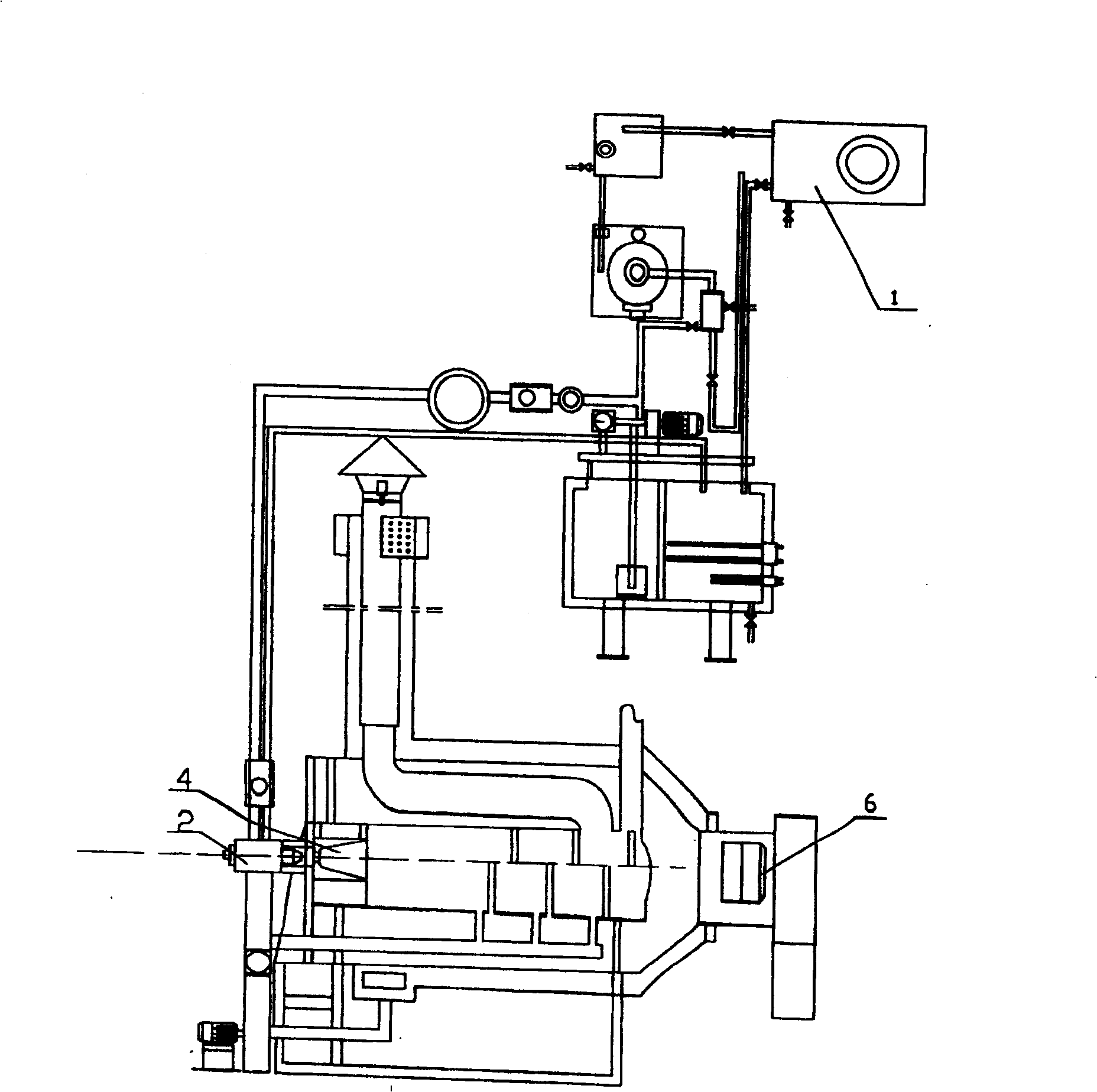

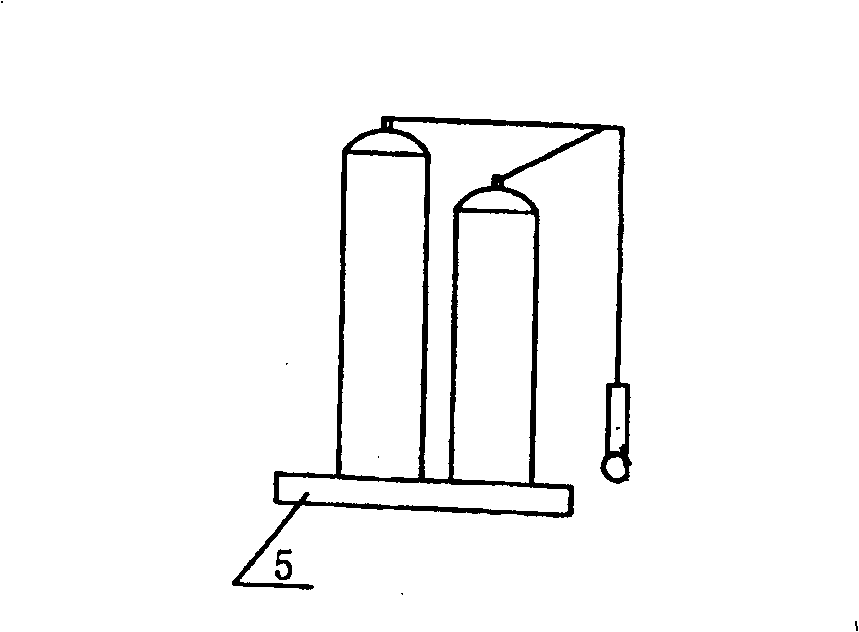

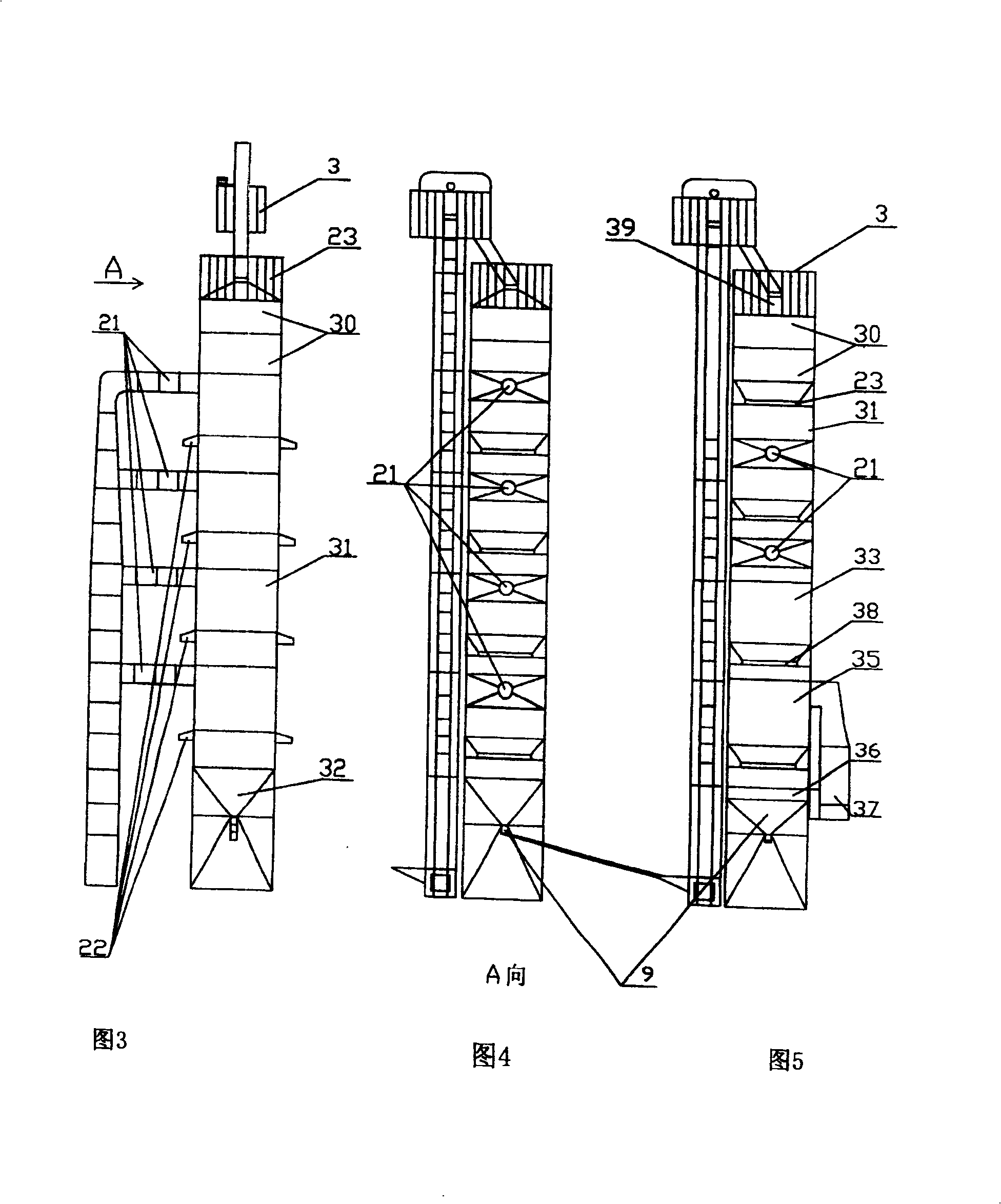

[0019] A complete set of heavy oil-fired grain drying equipment, including a heavy oil tank 1, a hot air stove 2, and a drying tower 3. The heavy oil tank 1 is equipped with multiple rows of double-row steam pipes, and its horizontal error is not more than two thousandths; A hearth preheating device 5 is arranged at the front part of the hot blast stove 2; the preheating device 5 adopts the combined combustion of liquefied petroleum gas and oxygen to heat the furnace hearth. It is very easy to ignite when the chamber is baked to 600-800 ° C, and it is of great help to the improvement of the quality of hot air. The rear part of the hot blast stove 2 is provided with a protective plate 6; the setting of this protective plate 6 can effectively prevent the smog formed by insufficient combustion of heavy oil during low-temperature ignition from entering the tower and polluting the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com