Temperature-resistant microemulsified methanol diesel oil and preparation method thereof

A technology of micro-emulsion and methanol, which is applied in the petroleum industry, liquid carbon-containing fuel, fuel, etc., can solve the problems of engine oil pipeline gas blockage, easy stratification, unstable performance, etc., and achieve improved turbidity and good performance. Catalytic synthesis effect, miscibility and stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

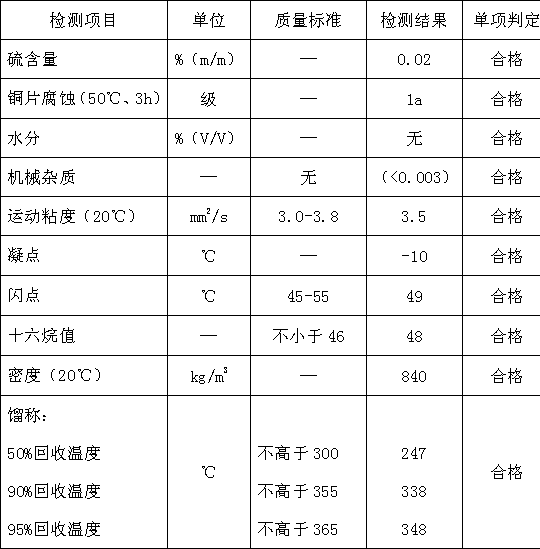

Embodiment 1

[0021] Take 65% of diesel oil, 15% of water, 5% of methanol, 10% of emulsifier and 5% of cetane number improver according to the percentage of mass fraction, stir well and then let stand.

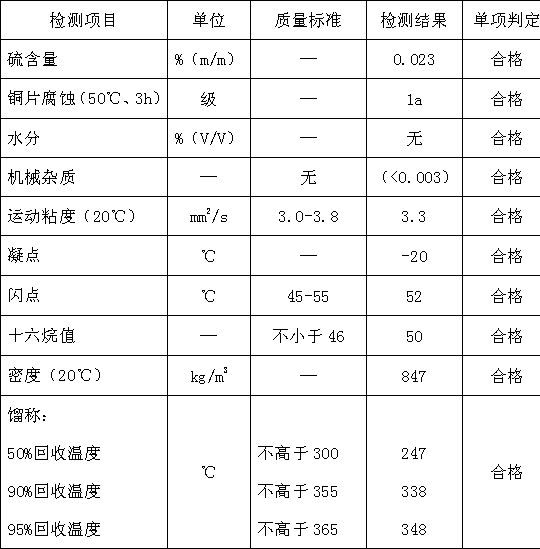

Embodiment 2

[0023] Take 67% of diesel oil, 13% of water, 5% of methanol, 9% of emulsifier and 6% of cetane number enhancer according to the percentage of mass fraction, stir well and then let stand.

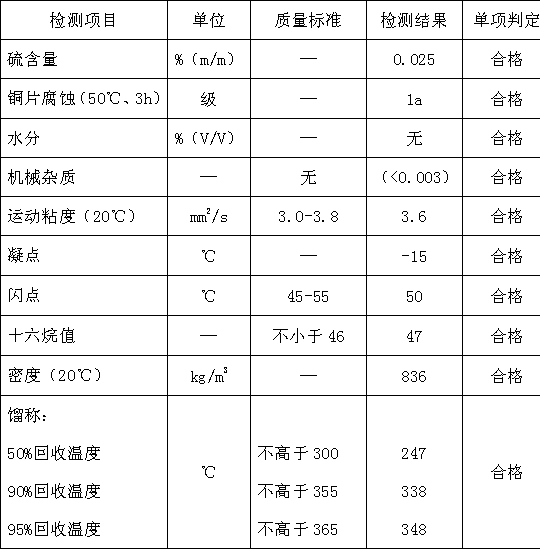

Embodiment 3

[0025] Take 70% of diesel oil, 15% of water, 3% of methanol, 7% of emulsifier and 5% of cetane number improver according to the percentage of mass fraction, stir well and then let stand.

[0026] The emulsifier consists of yeast 15-25%, flour enzyme 15-25%, sodium dodecylbenzenesulfonate 5-15%, fatty alcohol polyoxyethylene ether 5-15%, absolute ethanol 5-15% %, 5-10% urea, 1-5% dimethylamide, 0-5% potassium hydroxide and 5-10% cyclohexylamine.

[0027] In each of the above examples, the cetane number enhancer is composed of 7-12% solvent naphtha, 32-37% isooctyl nitrate, 3-7% nitromethane, 6-10% alkyl nitrate, acetone 4-7%, 4-6% alkylphenol polyoxyethylene ether, 18-22% nitro thinner, 4-6% iso-octanol, 4-6% n-octanol and 0-2% oily fragrance, Preferably, the cetane number enhancer consists of 10% solvent naphtha, 35% isooctyl nitrate, 5% nitromethane, 8% alkyl nitrate, 6% acetone, and alkylphenol polyoxyethylene ether 5%, nitro thinner 20%, iso-octanol 5%, n-octanol 5% and o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com