Modified clay base water-guiding materials and process for preparing same

A clay and water technology, applied in soil conditioning materials, chemical instruments and methods, organic fertilizers, etc., can solve the problems of water shortage in vegetation, underutilization of clay and fly ash, and difficulty in surviving, and achieve the goal of solving water shortage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

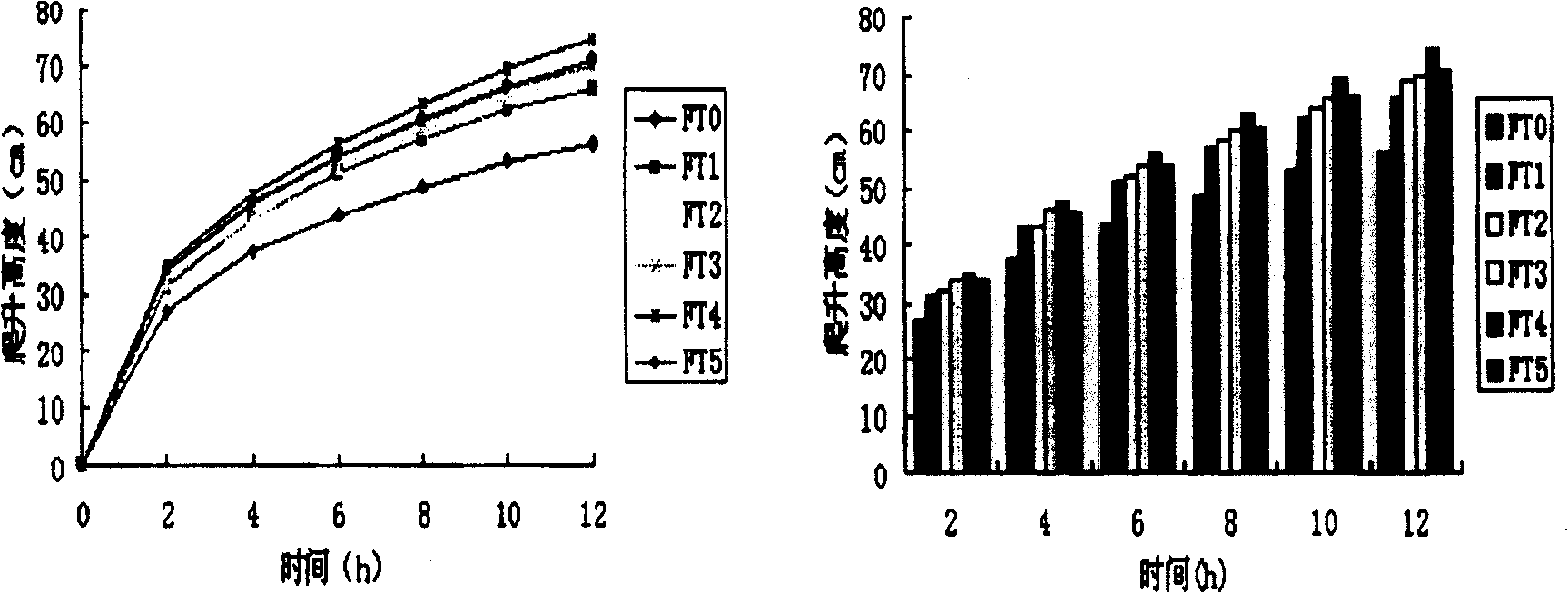

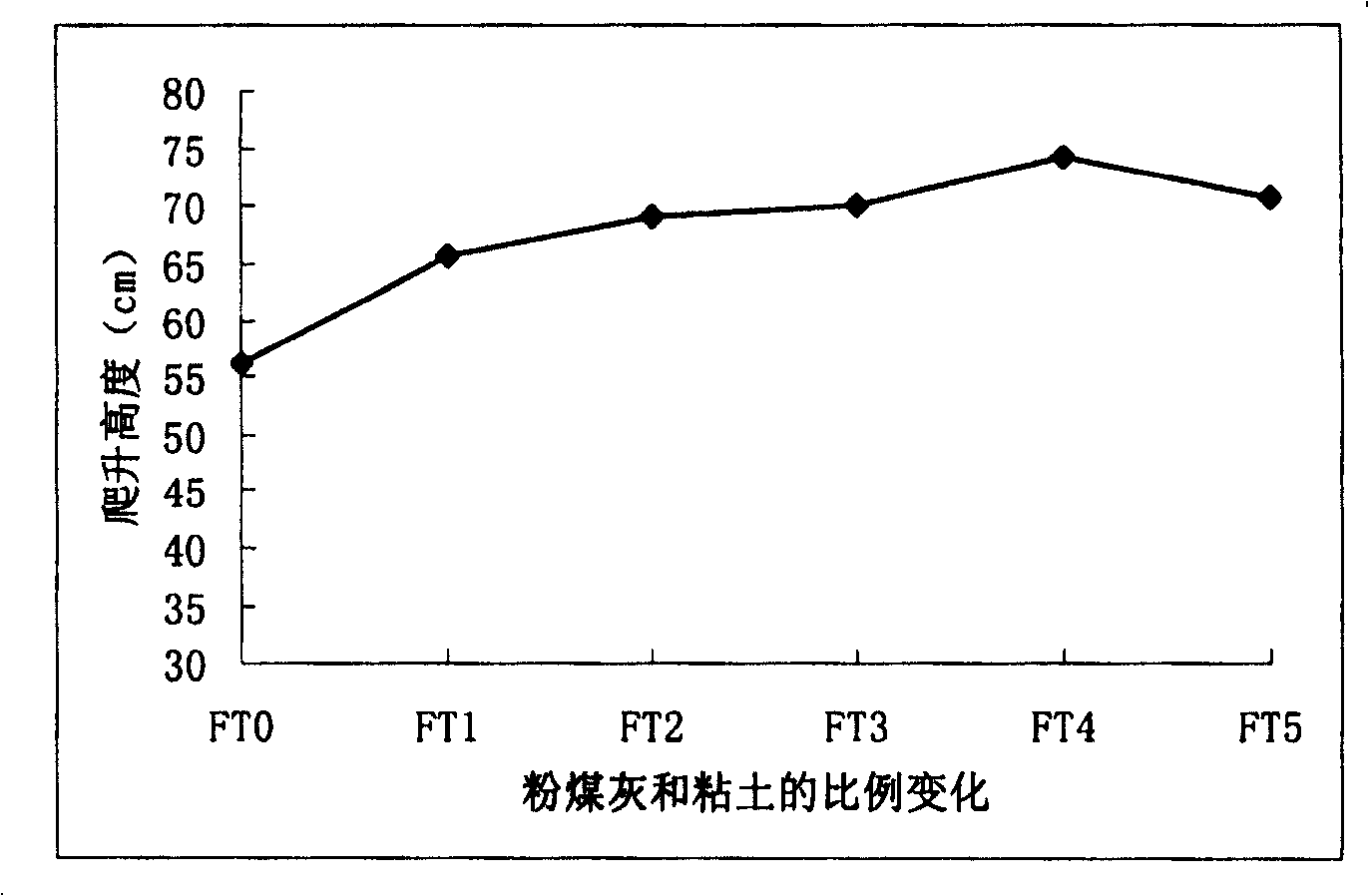

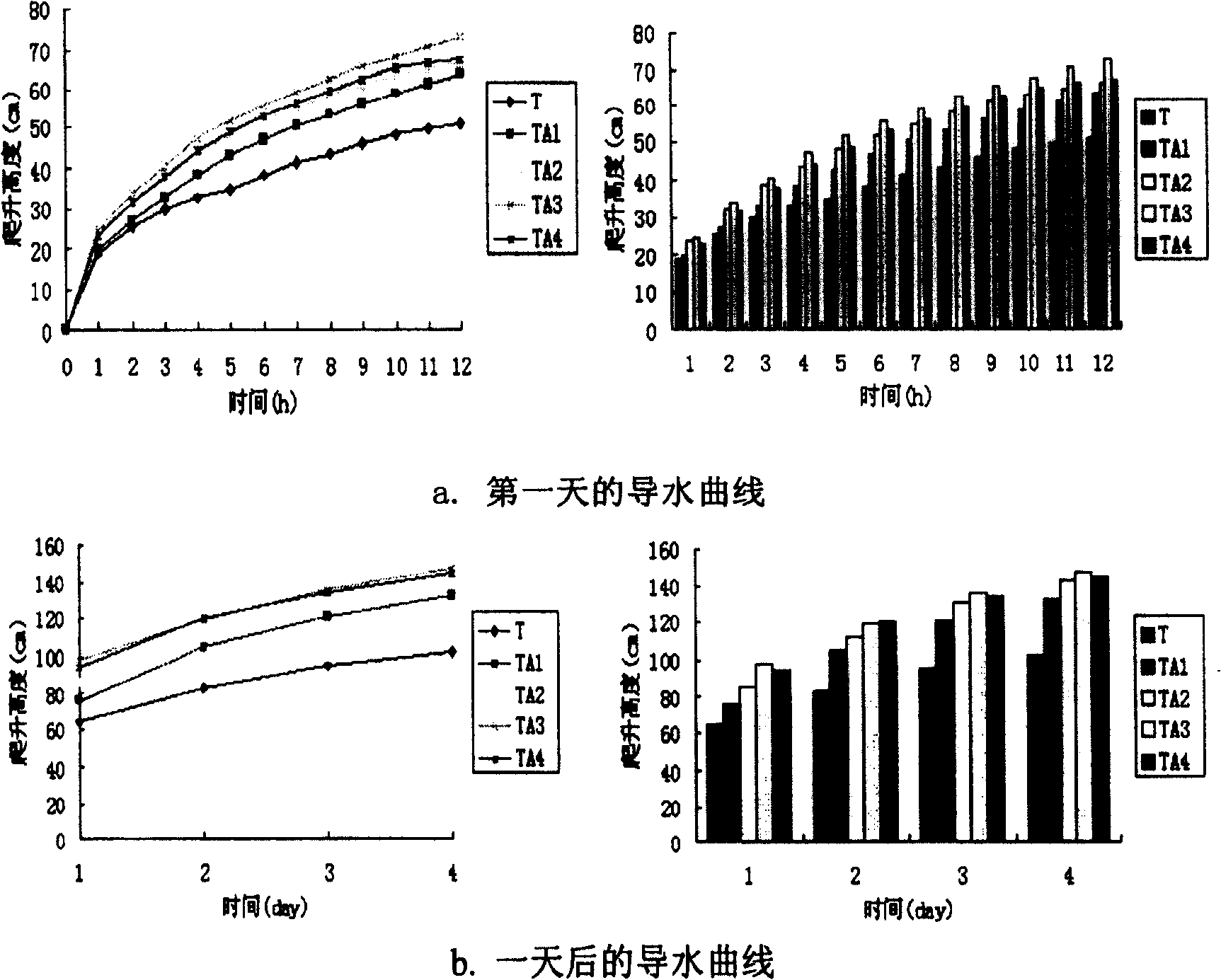

Examples

Embodiment 1

[0041] The formula that present embodiment adopts is as follows:

[0042] Fly ash: clay = 5:95.

[0043] Described clay refers to ordinary clay.

[0044] The preparation method is as follows:

[0045] Weigh the fly ash and clay according to the ratio and mix them evenly.

[0046] Specific steps are as follows:

[0047] 1) prepare the mud containing soil particle size less than 0.15mm at the tree planting site;

[0048] 2) A plastic film is made into a cylindrical outer cylinder. 3) Put the mixture of fly ash and soil into the outer cylinder, and seal both ends (water diversion body);

[0049] 4) Drill vertical holes down to the underground wet layer at the bottom of the dug tree pit;

[0050] 5) Open the two ends of the sealed water diversion body and put it into the vertical hole;

[0051] 6) Plant seedlings in the tree pit and pour enough water once.

[0052] The use of the novel modified clay provided by the invention can effectively solve the problem that current c...

Embodiment 2

[0054] The formula that present embodiment adopts is as follows:

[0055] Fly ash: clay = 25:75.

[0056] The clay refers to the polyhydroxy aluminum ion modified clay.

[0057] The preparation method is as follows:

[0058] Weigh the fly ash and aluminum crosslinking agent modified clay according to the ratio and mix them evenly.

[0059] The preparation method of polymerized hydroxyl aluminum ion modified clay is as follows:

[0060] 1) Prepare 1.0mol / L NaOH solution and 0.5mol / L AlCl 3 solution;

[0061] 2) Under stirring, slowly add the prepared NaOH solution to an equal volume of AlCl 3 in solution;

[0062] 3) Aging at 70°C for 4 hours and aging at room temperature for 2 weeks to obtain a floc crosslinking agent;

[0063] 4) drying the ordinary clay, pulverizing it, passing through a 150-mesh sieve, and preparing a clay suspension with a concentration of 15%;

[0064] 5) Dilute the cross-linking agent prepared in step 3 to a 0.2mol / L solution, slowly add it dropw...

Embodiment 3

[0076] The formula that present embodiment adopts is as follows:

[0077] Fly ash: clay = 5:95.

[0078] The clay refers to the aluminum crosslinking agent modified clay.

[0079] The preparation method is as follows:

[0080] Weigh the fly ash and polyhydroxy aluminum ion modified clay according to the ratio, and mix them evenly.

[0081] The preparation method of aluminum crosslinking agent modified clay is as follows:

[0082] 1) Prepare 1.0mol / L NaOH solution and 0.5mol / L AlCl 3 solution l;

[0083] 2) Under stirring, slowly add the prepared NaOH solution to an equal volume of AlCl 3 in solution;

[0084] 3) Aging at 70°C for 4 hours and aging at room temperature for 2 weeks to obtain a floc crosslinking agent;

[0085] 4) drying the clay, pulverizing it, passing through a 150-mesh sieve, and preparing a clay suspension with a concentration of 15%;

[0086] 5) Dilute the prepared cross-linking agent to 0.2mol L -1 The solution is slowly added dropwise to the clay ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com