Structure of electric screwdriver arrested by non-contact electromagnetic induction

An electric screwdriver and electromagnetic induction technology, applied in the direction of electrical components, electronic switches, motor tools, etc., can solve the problems of high parts processing requirements, poor reliability, short life, etc., to achieve reliable operation, high signal acquisition accuracy, The effect of simplifying the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Through the following description, the technical essence of the present invention will be more clearly understood, and the advantages and effects of the present invention will become clearer. However, the examples should not be regarded as limitations on the solutions of the present invention.

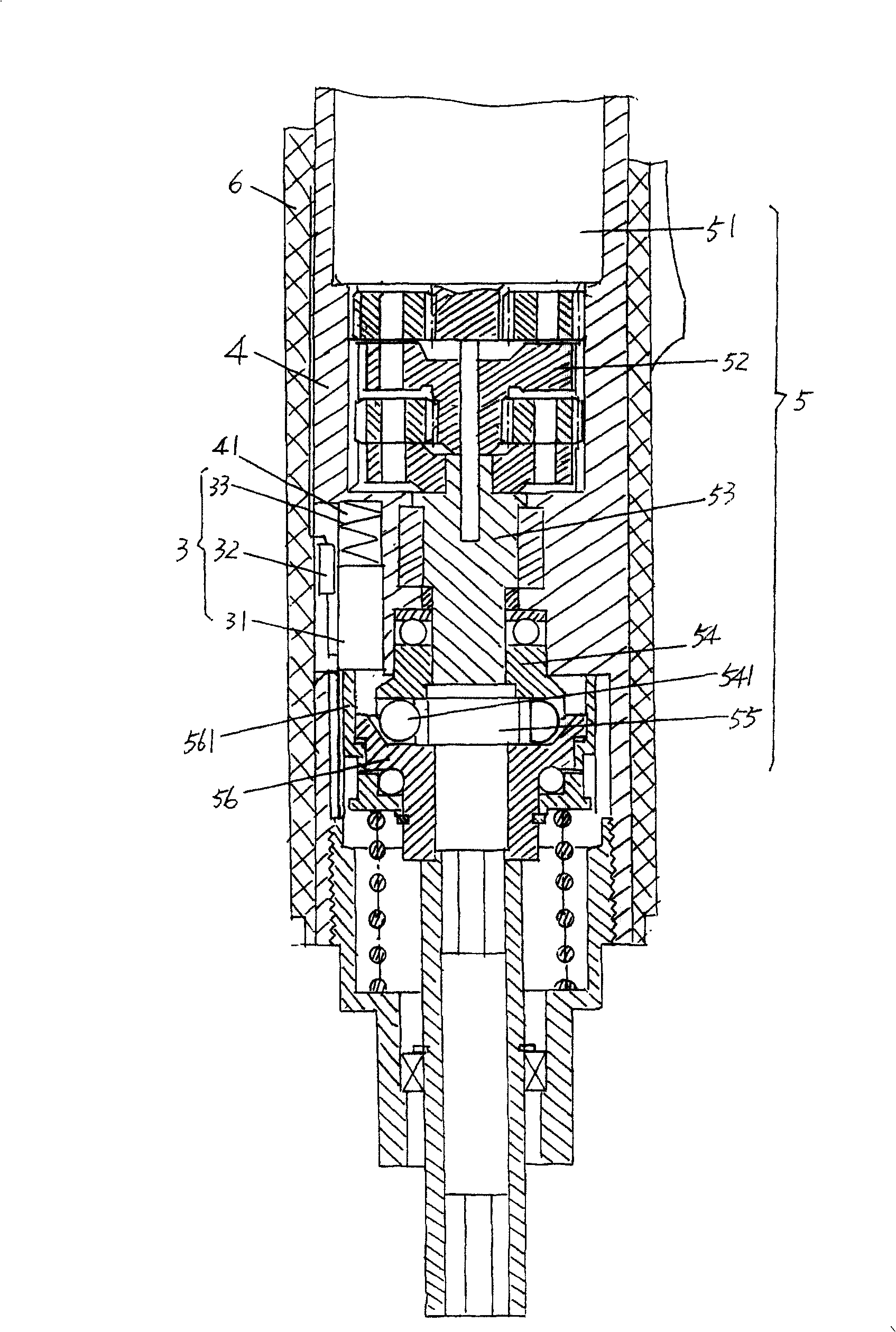

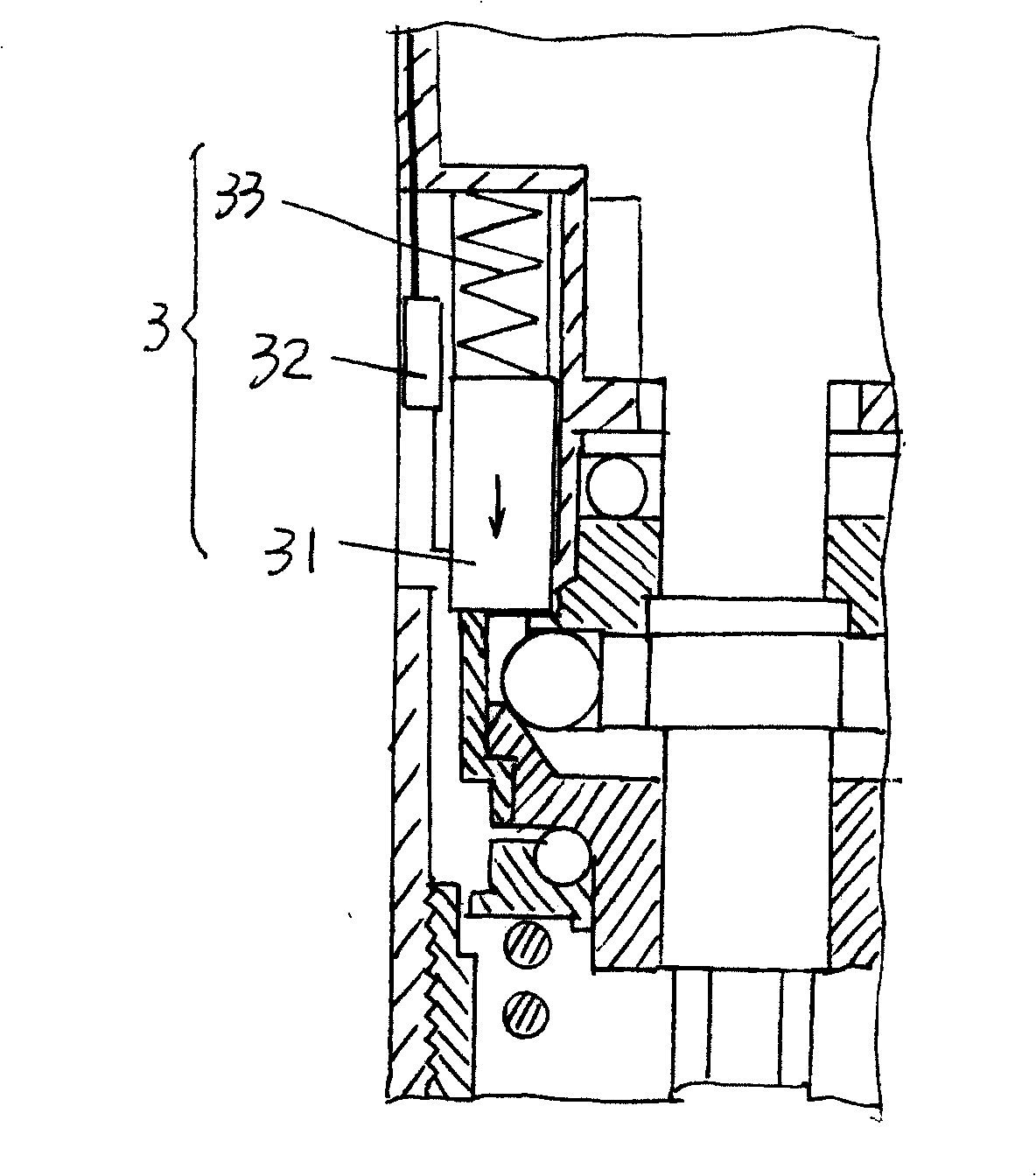

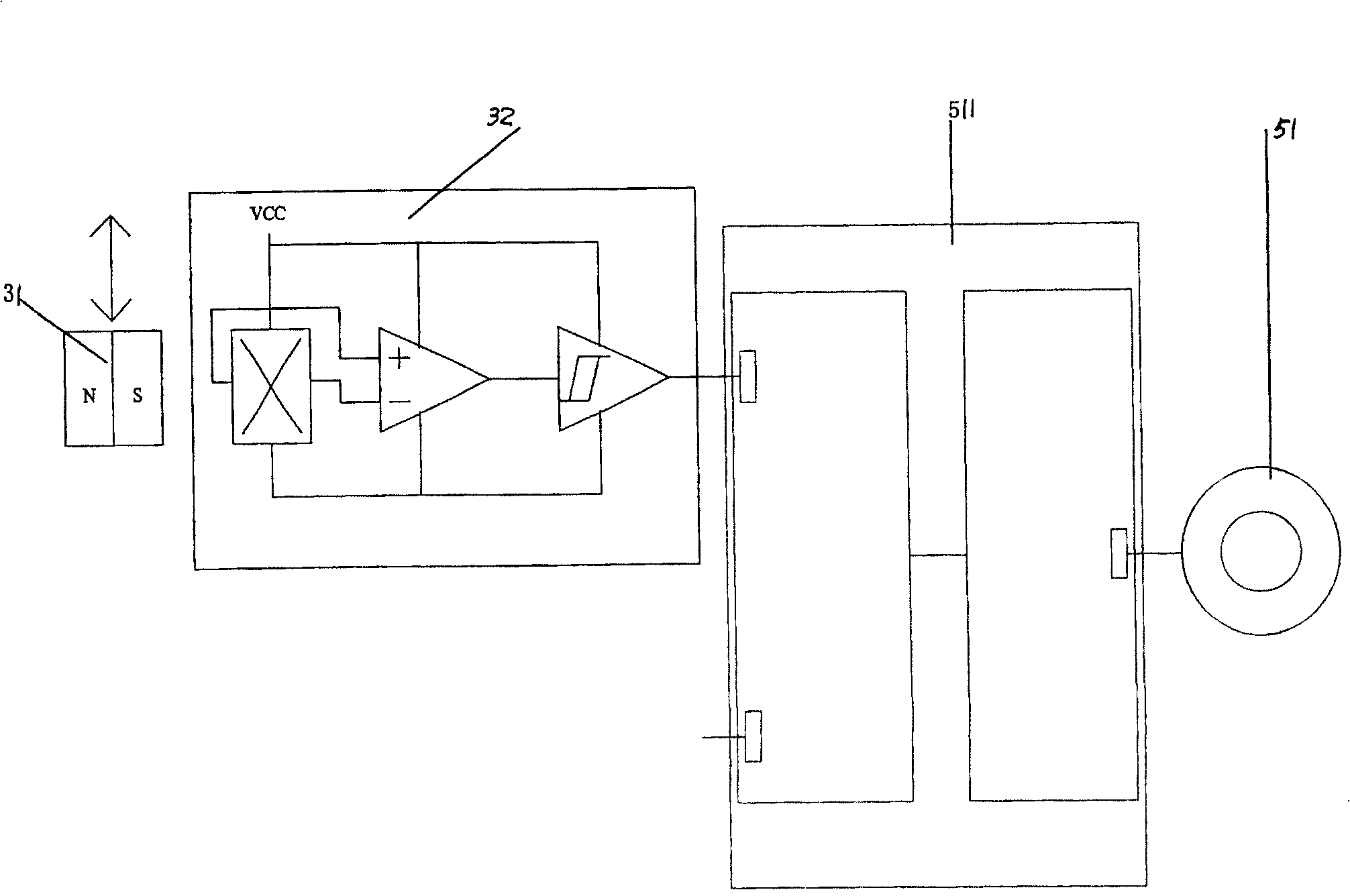

[0019] please see figure 1 and figure 2 as well as image 3 As an electric screwdriver, it is the same as the prior art such as CN2851620Y mentioned above, and also includes a housing 6, and the housing 6 is usually molded by plastic, and the preferred material installed in the shell cavity of the housing 6 is metal Such as the middle sleeve 4 made of aluminum alloy, a power transmission device 5 is arranged in the sleeve cavity of the middle sleeve 4, and the power transmission device 5 at least includes a motor 51, a deceleration assembly 52, an intermediate shaft 53, a transmission bowl 54, a camshaft 55, and a cone. Shaped disc 56. A missing portion is formed on the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com