Vibration pipe-sinking wind pile-pressing machine

A wind pressure and pile driver technology, which is applied in sheet pile walls, soil protection, construction, etc., can solve the problems of high cost of foundation treatment, inability to realize one-time feeding into piles, and difficult discharge of groundwater, so as to save foundation treatment cost, improve the bearing capacity and modulus of the foundation, and the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

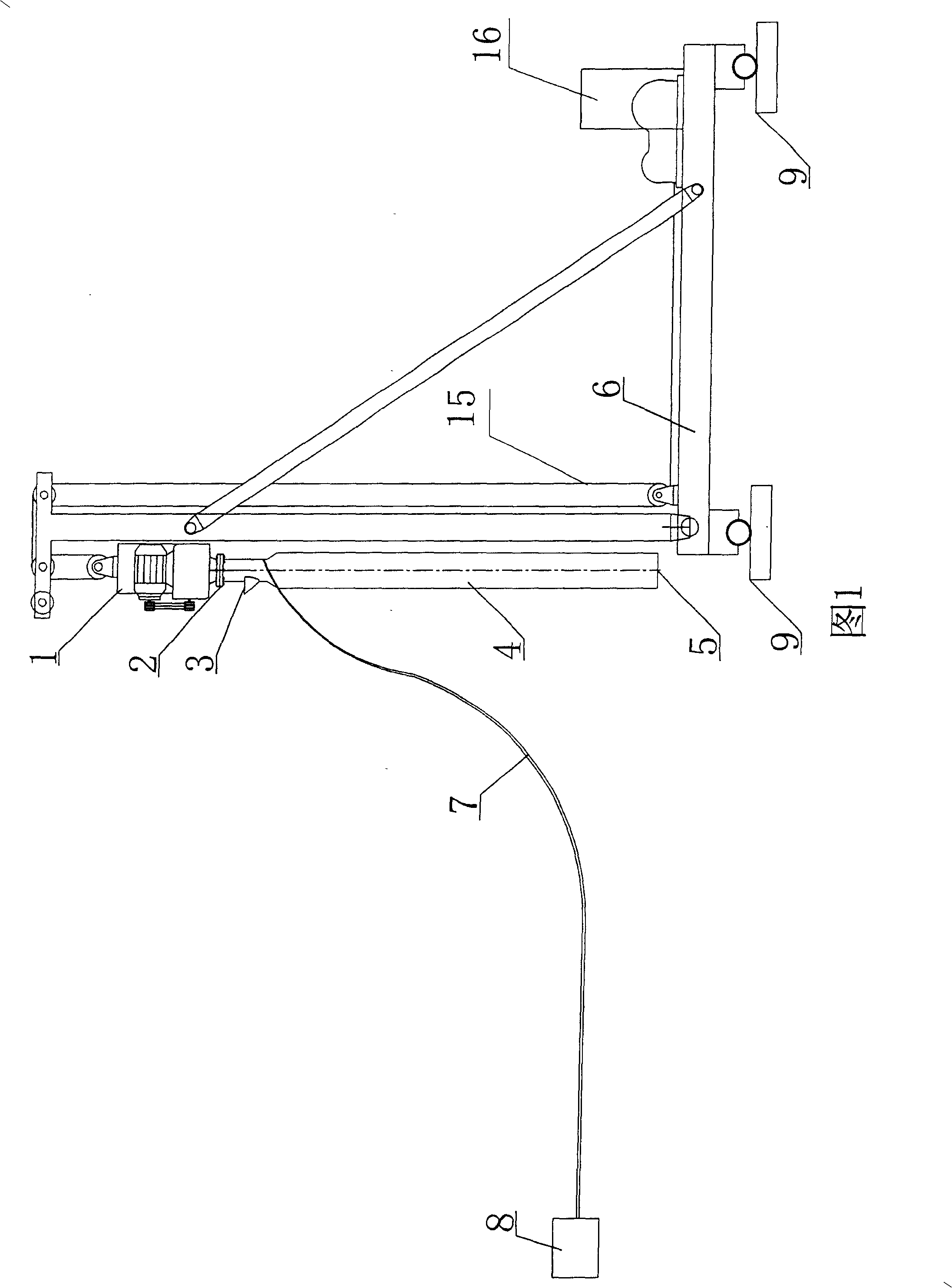

Embodiment 1

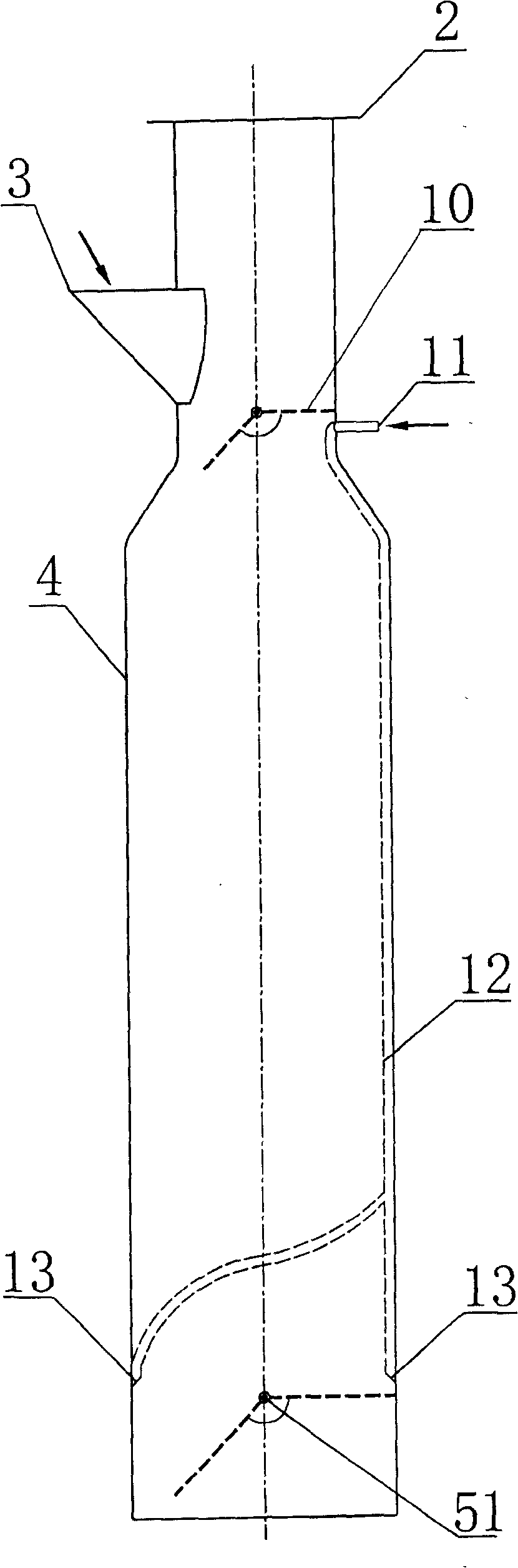

[0031] Example 1 see Figure 2-4 , the above-mentioned air supply steel pipe is an attached air supply steel pipe 12 close to the inner wall of the pile pipe, and its air inlet 11 is located on the pile pipe wall opposite to the feed inlet below the one-way valve. The pile tube lower end discharge port of the above-mentioned vibrating tube sinking wind pile machine is connected with a built-in pile shoe 51, which is built in the pile tube by 2 or more steel pile shoe plates, and is closed when the tube is immersed. The above-mentioned one-way valve and the built-in spud can are two semicircular blades hinged on the hinge axis crossing the pipe wall, and a return spring is connected between the semicircular blades and the central shaft. The one-way valve is opened when feeding, and closed when pneumatically feeding.

[0032] see image 3 , the lower end discharge port of the pile tube of the above-mentioned vibrating tube sinking wind pile machine is connected with a movable ...

Embodiment 2

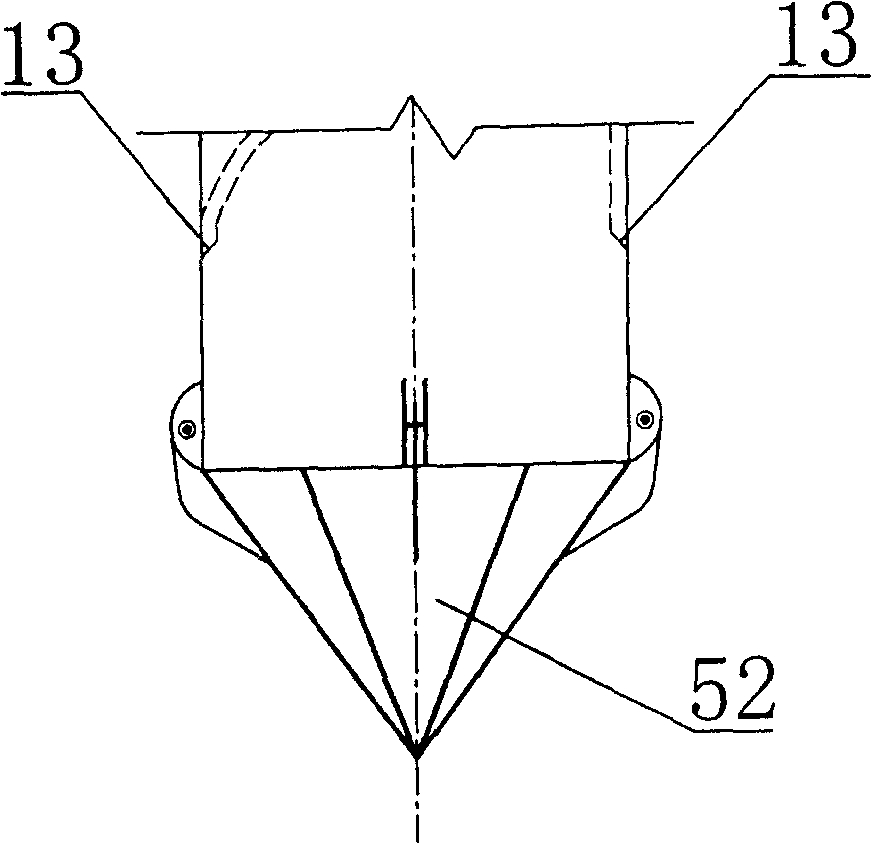

[0034] Example 2 see Figure 5 , the above-mentioned air supply steel pipe is an external air supply steel pipe 14 close to the pile pipe outer wall, its lower end passes through the pile pipe wall, the lower end of the air supply steel pipe is bifurcated, and two to four air outlets 13 are separated. The air outlet is distributed on the inner wall of the pile pipe, and can be equipped with a one-way air outlet valve.

[0035] Apply pile driver of the present invention to carry out the construction steps of foundation treatment:

[0036] Step 1, the pile driver is in place, the pile tube is aligned with the pile position and the verticality is adjusted, and the variable diameter pile tube is used. The pile hole formed by the variable diameter pile tube is larger than the designed pile diameter, which is conducive to the discharge of the pile material from the pile tube to form a pile.

[0037] Step 2. Start the pile driver, so that the vibrating hammer head drives the pile pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com