Safety early warning system for monitoring corrosion, leakage of pipeline on active service, and control method

A safety monitoring and early warning system technology, applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve problems such as lack of monitoring, unrepresentation, and inability to solve the problem of differential corrosion or perforation monitoring of pipelines. Achieve the effect of short construction period, convenient maintenance and migration, and quick installation and opening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

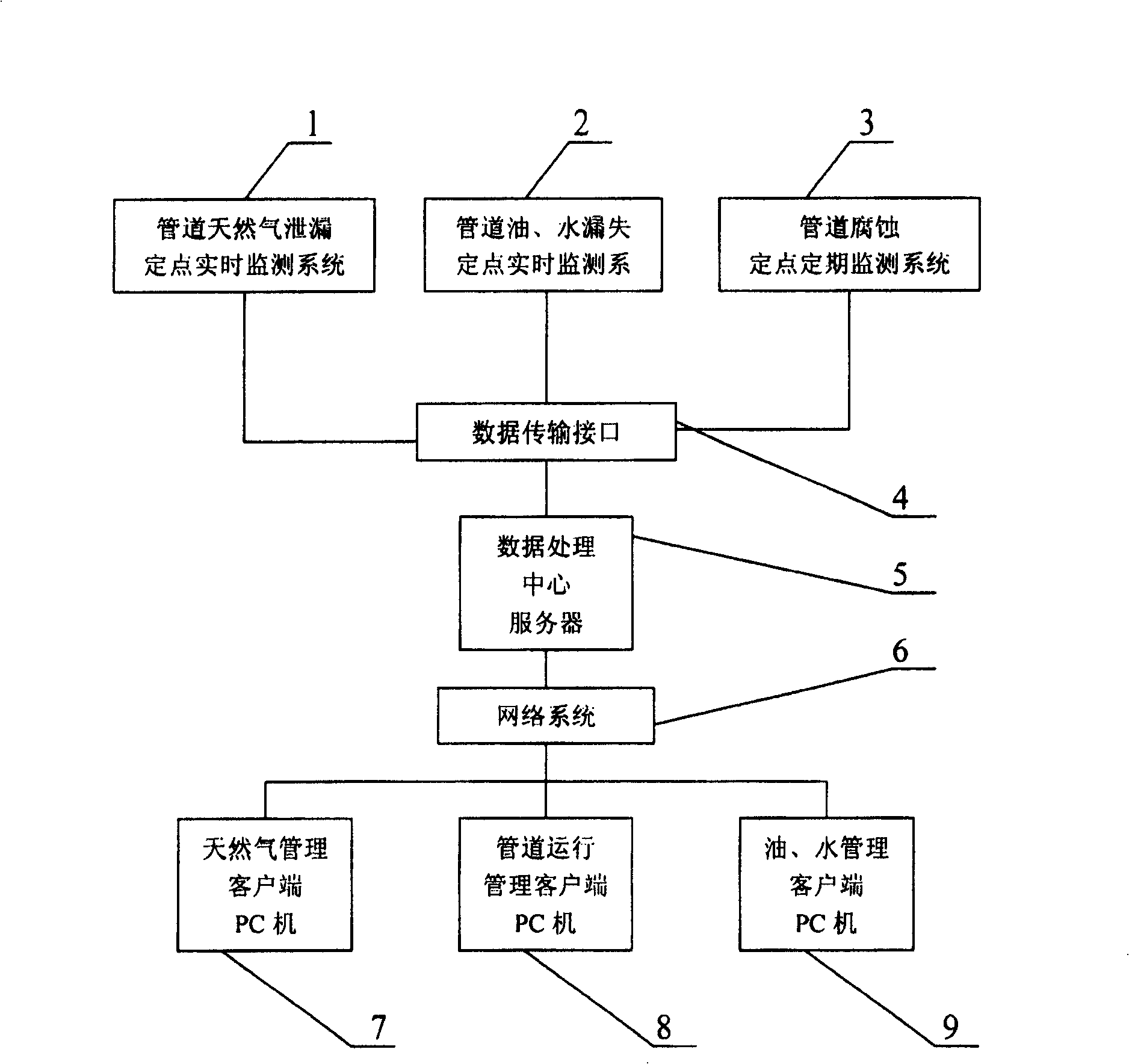

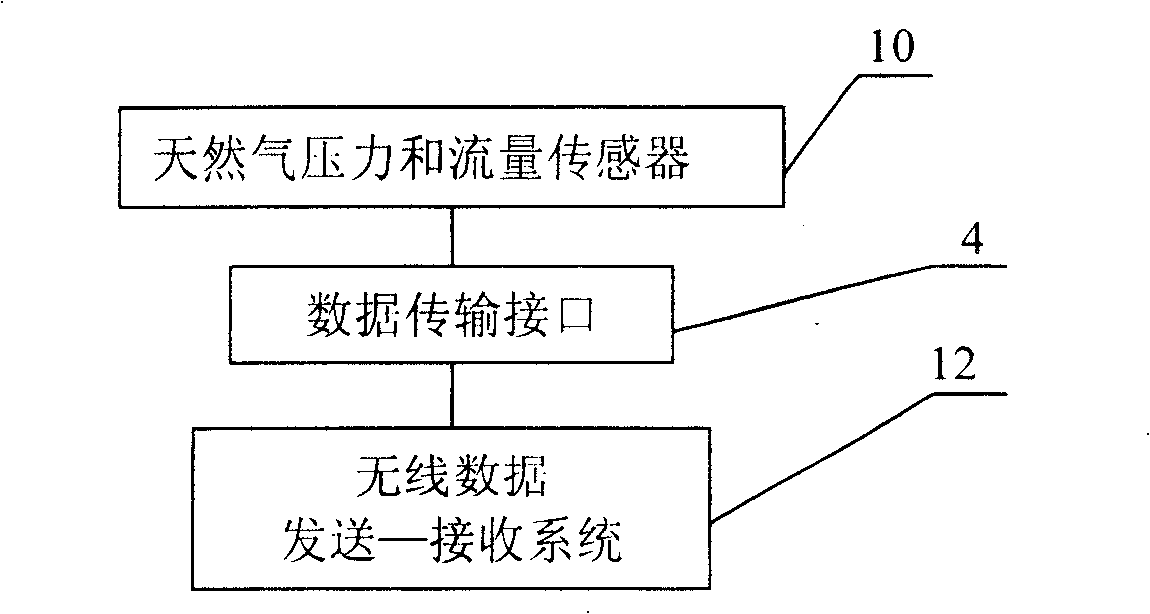

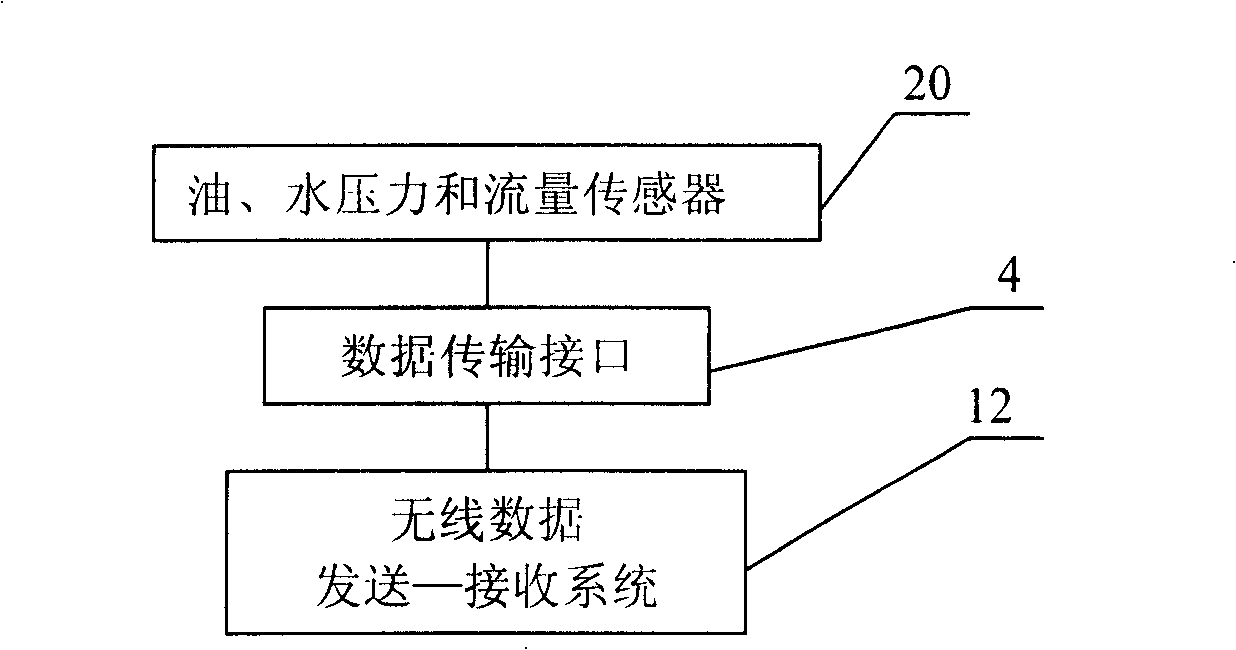

[0061] refer to figure 1: In-service pipeline corrosion and leakage safety monitoring and early warning system consists of: pipeline natural gas leakage fixed-point real-time monitoring system 1, pipeline oil and water leakage fixed-point timing monitoring system 2, pipeline corrosion periodic detection system 3, data transmission interface 4, data processing center server 5. Network system 6. Natural gas management client PC 7. Pipeline operation management client PC 8. Oil and water management client PC 9. The fixed-point real-time monitoring system 1 for pipeline natural gas leakage or the fixed-point timing monitoring system 2 for pipeline oil and water leakage or the output end of the pipeline corrosion periodic detection equipment 3 is connected to the data processing center server 5 through the data transmission interface 4, and the data processing center server 5 is connected through the network The system 6 is connected with a natural gas management client PC 7 or an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com