Substrate transport container

A technology for substrates and containers, applied in the field of substrate transfer containers, can solve problems such as inability to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

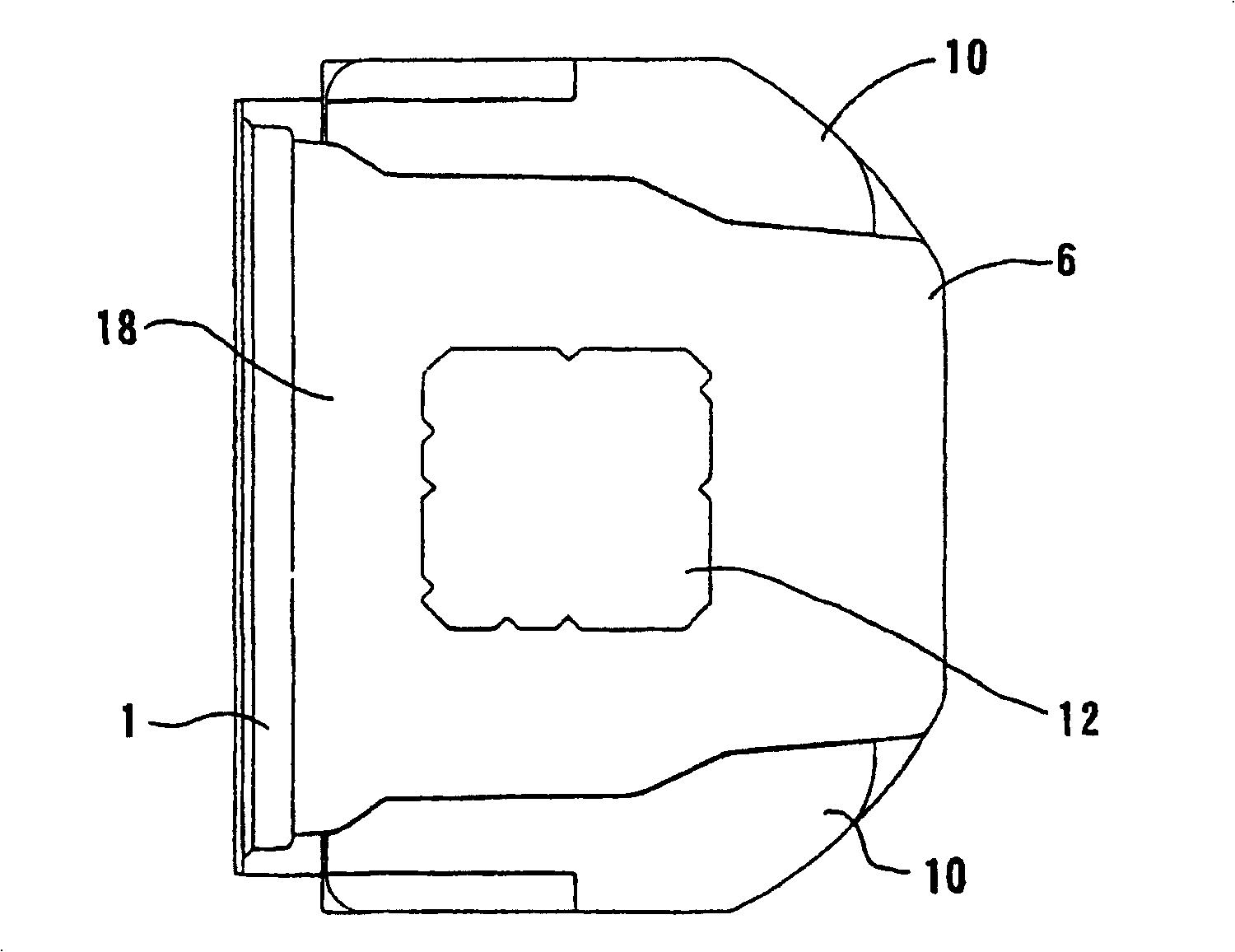

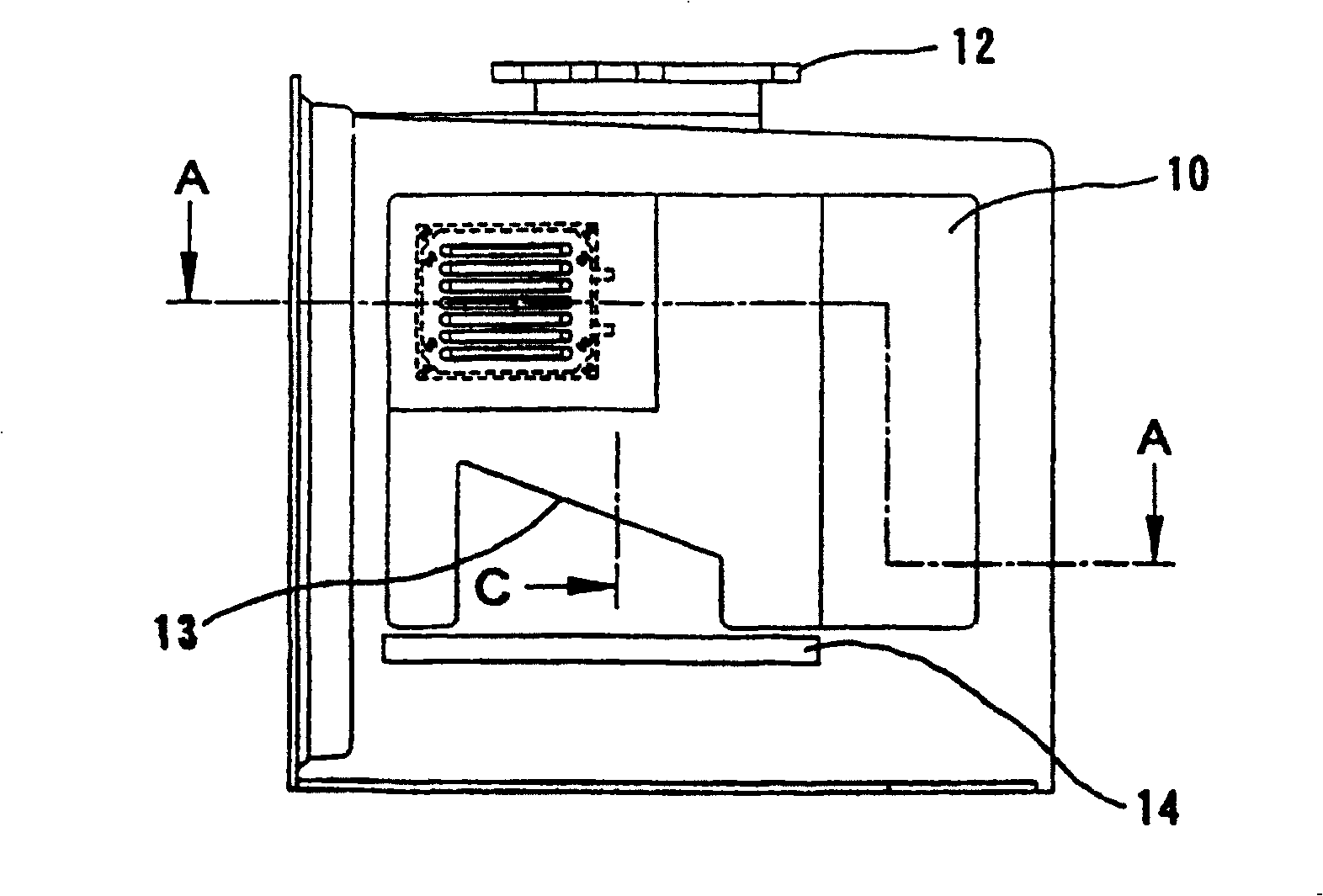

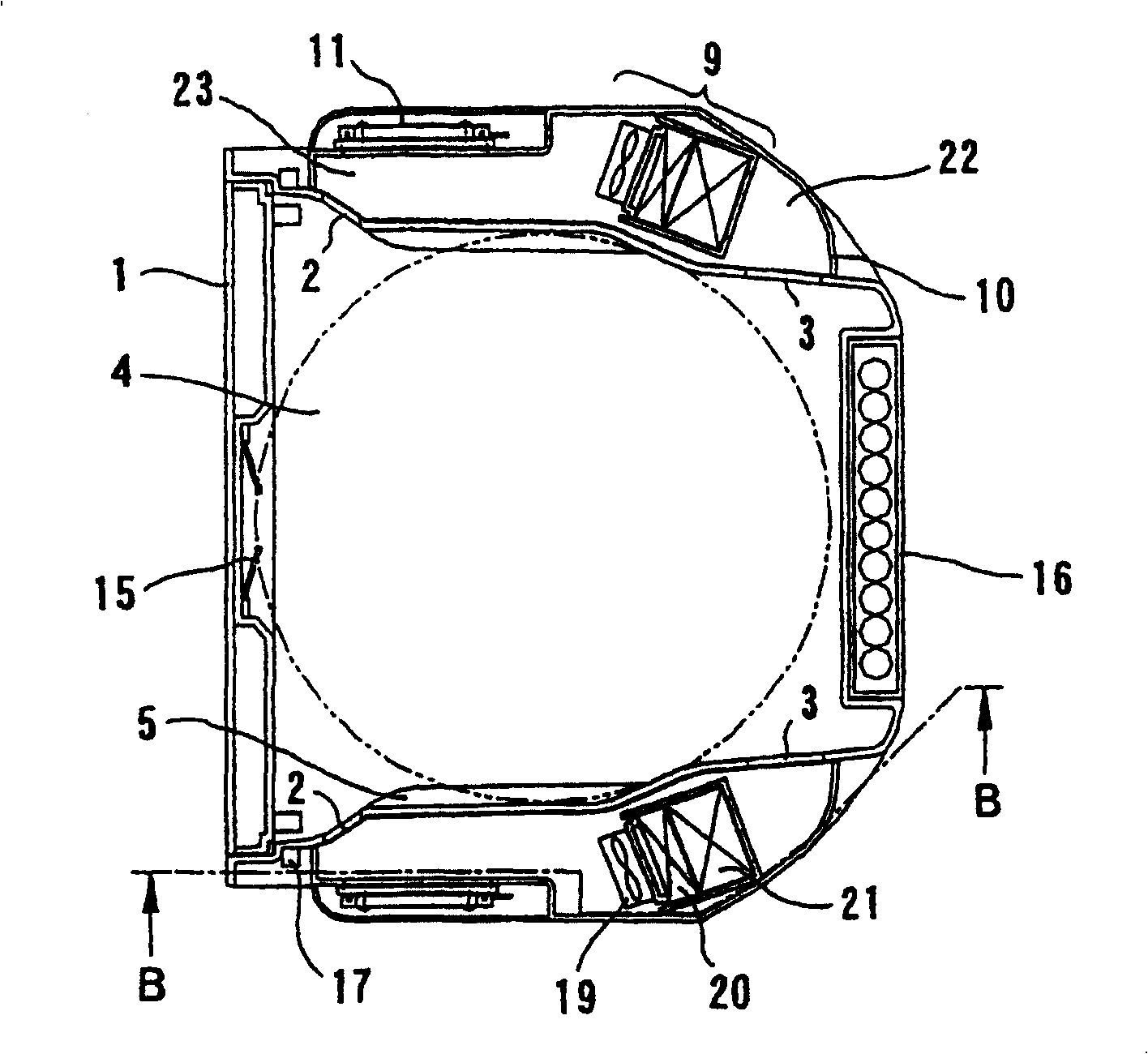

[0041] Preferred embodiments will be described below with reference to the accompanying drawings.

[0042] First, it is necessary to introduce a substrate transfer container (cassette) compatible with automatic operation of semiconductor device manufacturing equipment. In order to prevent human errors caused by operators and contamination of substrates such as semiconductor wafers with organic substances and trace amounts of ammonia gas generated by operators, it is effective to keep operators at a distance from a space for handling substrates. Therefore, there is a need to introduce process automation as a means of contamination for achieving this prevention. Substrate transfer containers used in such automated equipment include SMIF (Standard Mechanical Interface) containers and FOUP (Front Opening Unified Containers), which are used in combination with a door opening tool that sets the equipment at a special position and opens the door to the outside, and For use with auto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com