Regenerating preprocessing agent for inorganic membrane or ultrafilter membrane and preparation method thereof

A pretreatment agent and inorganic membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of short gas scouring time, unstable mechanical force, unstable peroxide, etc., to achieve The effect of shortening the membrane regeneration time, prolonging the service life, and improving the membrane regeneration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

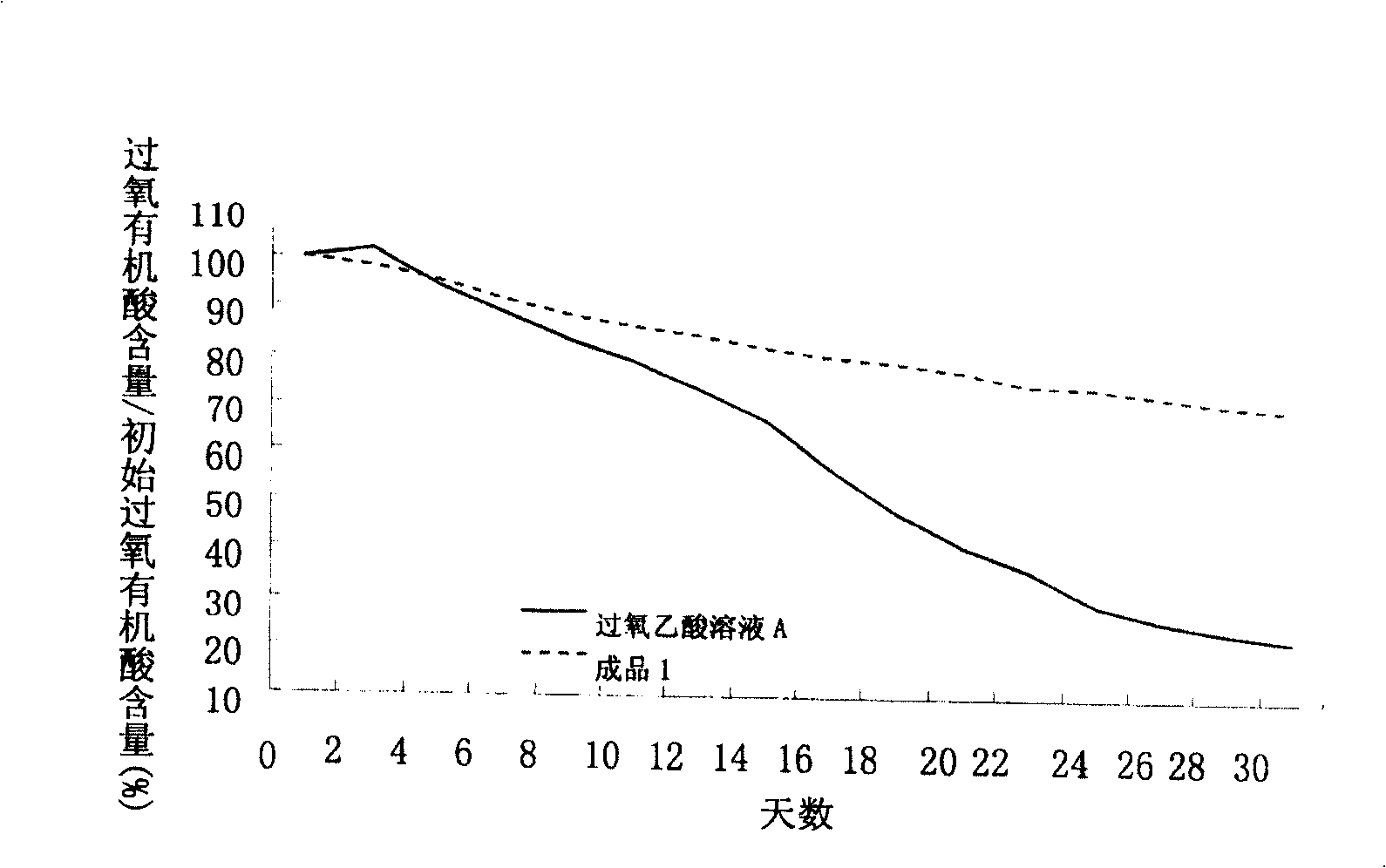

[0022] Get 1500g deionized water and add 1000g acetic acid, then add 1000g (50% hydrogen peroxide), stir so that acetic acid and hydrogen peroxide are completely dissolved in water; add 100.0g aminotrimethylene phosphonic acid to the above solution and then add about 300g nonanoic acid, heat up After stirring at 45°C for about 30 minutes, lower it to 25°C for later use; add about 5.0g of sodium dodecylbenzenesulfonate to the cooled solution, and then add deionized water to control the total mass to 5000g, and stir the solution evenly Store in an environment of 30±5°C for 9 days and then perfuse to obtain the finished product 1.

[0023] Take 1600g of deionized water and add 1300g of acetic acid, then add 1000g (50% hydrogen peroxide), stir to completely dissolve the acetic acid and hydrogen peroxide in the water; heat up to 45°C and stir for about 30 minutes, then drop to 25°C for later use; the solution after cooling Add about 5.0 g of sodium dodecylbenzene sulfonate, and the...

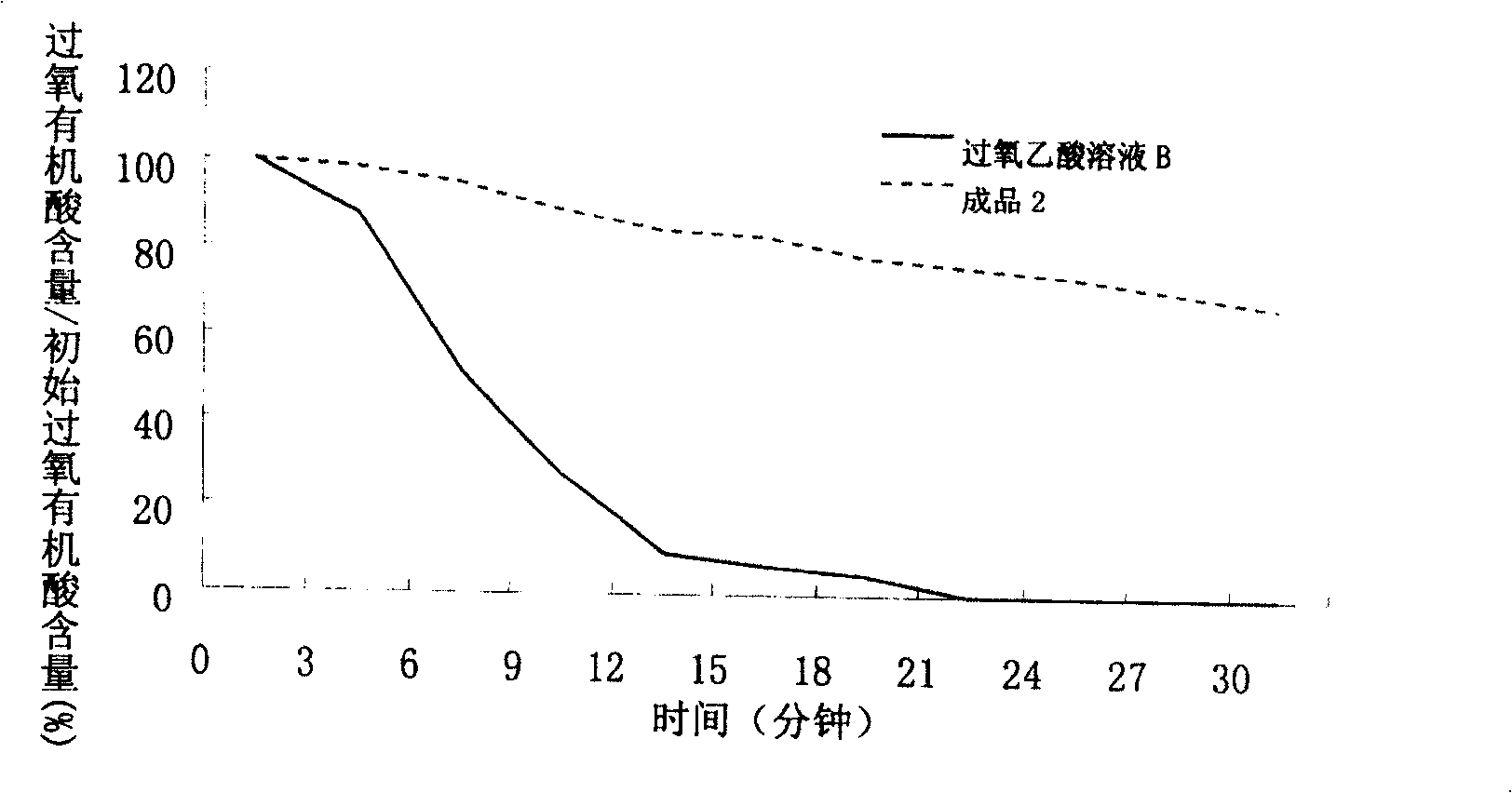

Embodiment 2

[0027] Get 1500g deionized water and add 1500g acetic acid, then add 1500g (50% hydrogen peroxide), stir so that acetic acid and hydrogen peroxide are completely dissolved in water; add 75.0g aminotrimethylene phosphonic acid to the above solution and then add about 200g nonanoic acid, heat up After stirring at 45°C for about 30 minutes, lower it to 25°C for later use; add about 2.5g of sodium dodecylbenzenesulfonate to the cooled solution, and then add deionized water to control the total mass to 5000g, and stir the solution evenly Store in an environment of 30±5°C for 9 days and then perfuse to obtain the finished product 3.

[0028] Take 1200g of deionized water and add 1500g of acetic acid, then add 1250g (50% hydrogen peroxide), stir to completely dissolve the acetic acid and hydrogen peroxide in the water; heat up to 45°C and stir for about 30 minutes, then drop to 25°C for later use; the solution after cooling Add about 3.7g of sodium dodecylbenzenesulfonate, and then a...

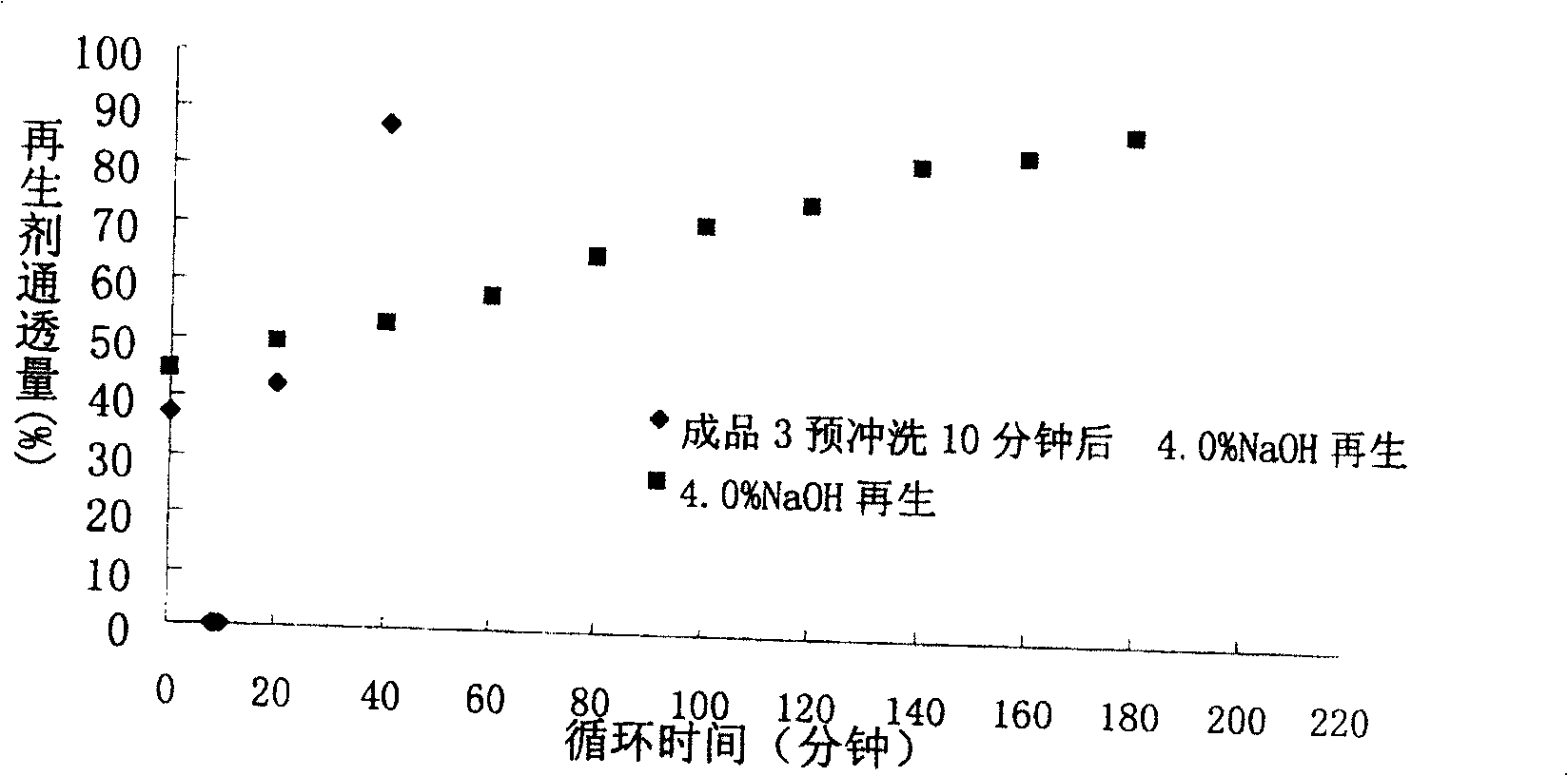

Embodiment 3

[0032] Get 1500g deionized water and add 1250g acetic acid, then add 1250g (50% hydrogen peroxide), stir so that acetic acid and hydrogen peroxide are completely dissolved in water; add 88.0g aminotrimethylene phosphonic acid and then add about 250g nonanoic acid in the above solution, heat up After stirring at 45°C for about 30 minutes, lower it to 25°C for later use; add about 3.7g of sodium dodecylbenzenesulfonate to the cooled solution, then add deionized water to control the total mass to 5000g, and stir the solution evenly Store in an environment of 30±5°C for 9 days and then perfuse to obtain the finished product 3.

[0033] Use deionized water to prepare an aqueous solution containing about 0.5% of the finished product 3 as a regeneration pretreatment agent, and pressurize the ceramic nanofiltration membrane that has filtered the aloe extract for about 7 hours for 10 minutes, and then use 4.0% hydrogen to oxidize Sodium solution is used for regeneration. Before the reg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com