Boric acid affinity rutin molecularly imprinted magnetic nanosphere as well as preparation method and application thereof

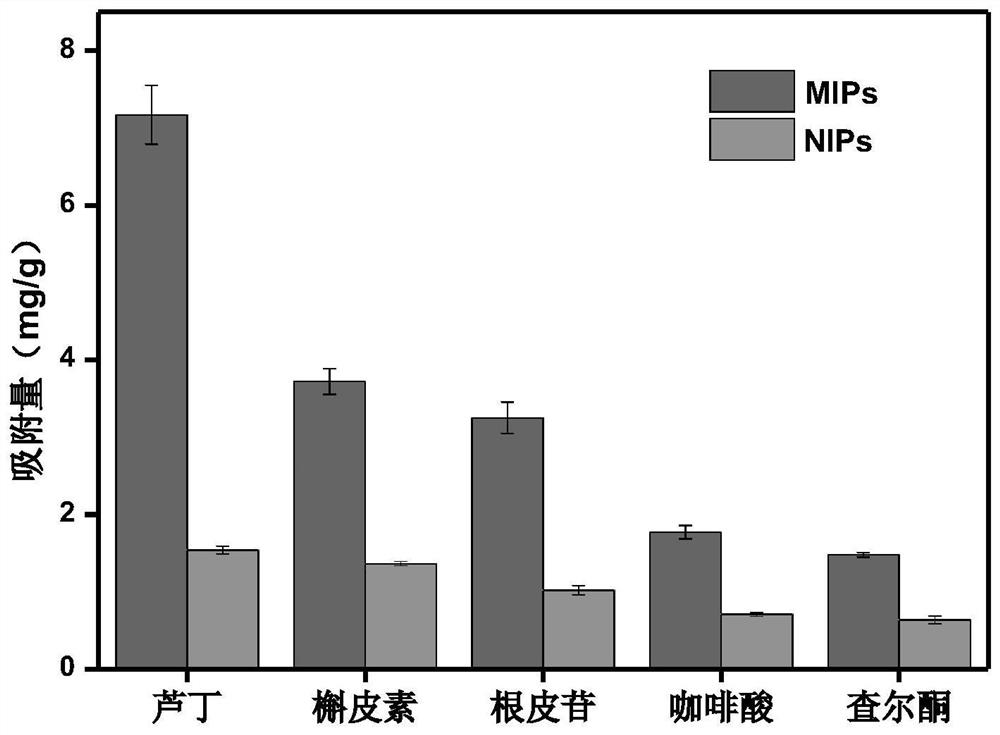

A technology of magnetic nanospheres and molecular imprinting, applied in separation methods, chemical instruments and methods, and other chemical processes, can solve the problems of low purity of rutin, and achieve simple and easy preparation methods, good water dispersibility, and enrichment Gentle effect of extraction method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

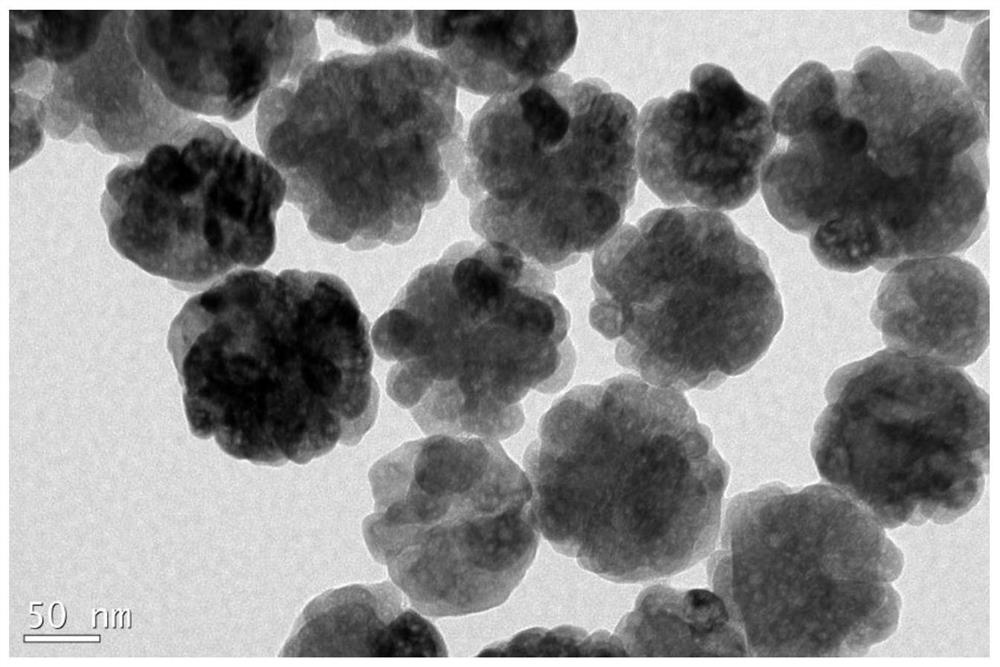

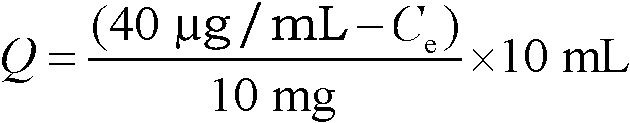

[0033] A method for preparing boric acid-affinity rutin molecularly imprinted magnetic nanospheres, comprising the following steps:

[0034] Step 1. Put 0.3g of ferric chloride, 1.0g of sodium acetate, 0.05g of sodium polyacrylate, 6mL of ethylene glycol and 10mL of diethylene glycol in a reaction kettle, and react at 150°C for 5 hours. After the reaction, put The reaction product was washed with ultrapure water until neutral. Then, the obtained product was dried at 30° C. and 0.05 MPa for 3 hours to obtain carboxyl magnetic nanospheres.

[0035]Step 2: 150 mg of carboxyl magnetic nanospheres, 150 mg of EDC and 100 mg of NHS were dissolved and dispersed in ultrapure water, and stirred and reacted at room temperature for 30 min. Then add 150 mg of 3-aminophenylboronic acid and stir for 4 h. After the reaction is completed, the reaction product is washed with ultrapure water until neutral. Then, the obtained product was dried at 30°C and 0.05MPa for 3 hours to obtain phenylbor...

Embodiment 2

[0047] A method for preparing boric acid-affinity rutin molecularly imprinted magnetic nanospheres, comprising the following steps:

[0048] Step 1. Put 0.5g of ferric chloride, 2.0g of sodium acetate, 0.08g of sodium polyacrylate, 7mL of ethylene glycol and 12mL of diethylene glycol in a reaction kettle, and react at 160°C for 8 hours. After the reaction, put The reaction product was washed with ultrapure water until neutral. Then, the obtained product was dried at 55° C. and 0.07 MPa for 6 hours to obtain carboxyl magnetic nanospheres;

[0049] Step 2: 180 mg of carboxyl magnetic nanospheres, 180 mg of EDC and 150 mg of NHS were dissolved and dispersed in ultrapure water, and stirred and reacted at room temperature for 40 min. Then add 180 mg of 3-aminophenylboronic acid and stir for 5 h. After the reaction, the reaction product is washed with ultrapure water until neutral. Then, the obtained product was dried at 55° C. and 0.07 MPa for 6 hours to obtain phenylboronic acid...

Embodiment 3

[0061] A method for preparing boric acid-affinity rutin molecularly imprinted magnetic nanospheres, comprising the following steps:

[0062] Step 1. Put 0.8g of ferric chloride, 3.0g of sodium acetate, 0.08g of sodium polyacrylate, 8.0mL of ethylene glycol and 14mL of diethylene glycol in a reactor, and react at 170°C for 10 hours. After the reaction, The reaction product was washed with ultrapure water until neutral. Then, vacuum-dry the obtained product at 40°C and 0.08MPa for 6.5h to obtain carboxyl magnetic nanospheres;

[0063] Step 2: 200 mg of carboxyl magnetic nanospheres, 200 mg of EDC and 160 mg of NHS were dissolved and dispersed in ultrapure water, and stirred and reacted at room temperature for 60 min. Add 2400 mg of 3-aminophenylboronic acid and stir for 5 h. After the reaction, the reaction product is washed with ultrapure water until neutral. Then, the obtained product was dried at 50°C and 0.07MPa for 6 hours to obtain phenylboronic acid-modified magnetic na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com