Automated control method for shaft kiln distributing device and the device

An automatic control and distributor technology, which is applied in the field of cement building materials, can solve the problems of increased maintenance workload of associated dust collectors, uniformity of distribution, influence on accuracy, and influence on temperature changes in the kiln, so as to reduce labor intensity of workers, Good operation effect and the effect of maintaining the temperature of the kiln surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

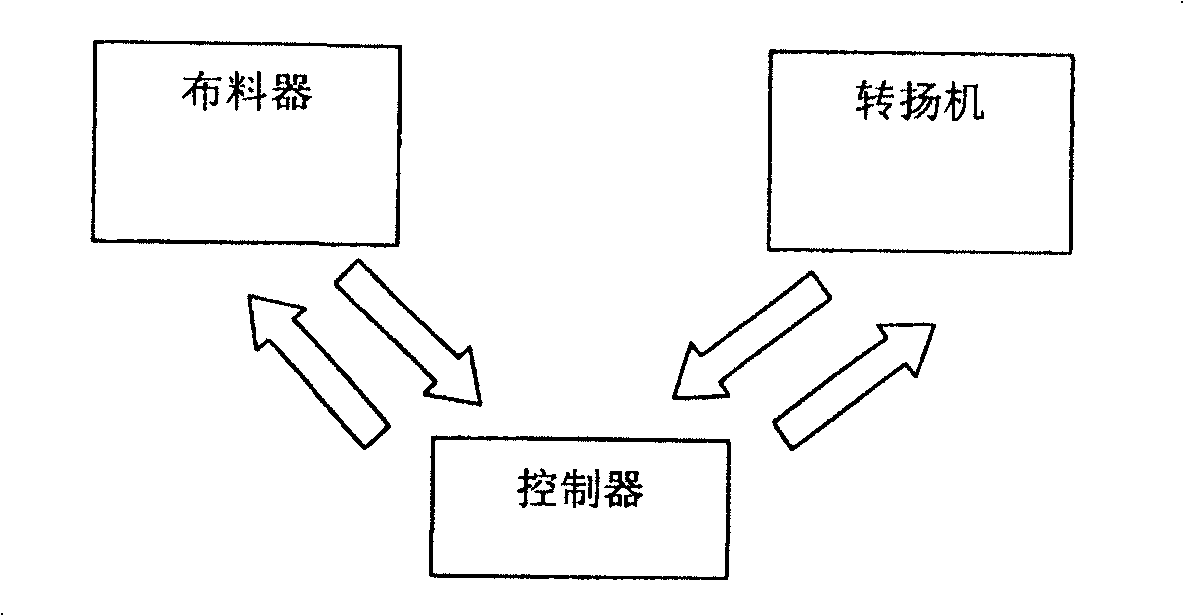

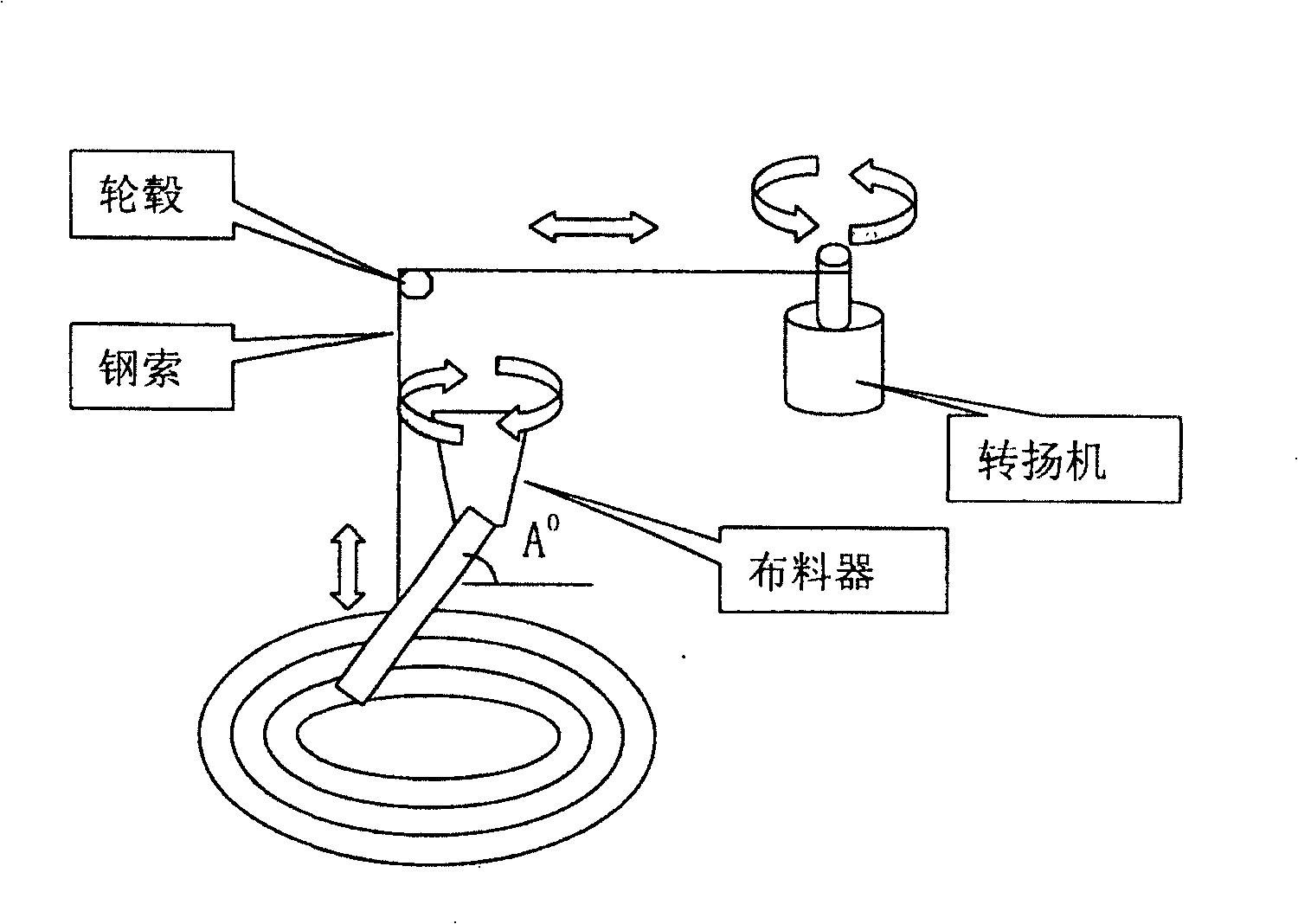

[0009] The automatic control method of the vertical kiln distributor, the method is that the program controller connects the signal for controlling the clockwise or counterclockwise rotation of the distributor to the input terminal of the distributor through its output terminal; Set one circle of cloth in the cloth; the cloth distributor rotates N times, and N circles of cloth are set in the cloth area; the program controller outputs the signal to control the steel wire on the hoist in a clockwise or counterclockwise direction or to stop rotating through it. The end is connected to the signal input end of the hoisting machine; the angle between the sprinkler disc and the horizontal plane of the distributor is controlled to change from 0 to 90 degrees through the rotation of the steel wire; according to the circumference of the distribution area, it is divided into three or more concentric circles for automatic layered distribution ; The distance between different circles and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com