Side-lighting type back light module

A backlight module, light incident surface technology, applied in optics, nonlinear optics, instruments, etc., to achieve the effect of improved conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

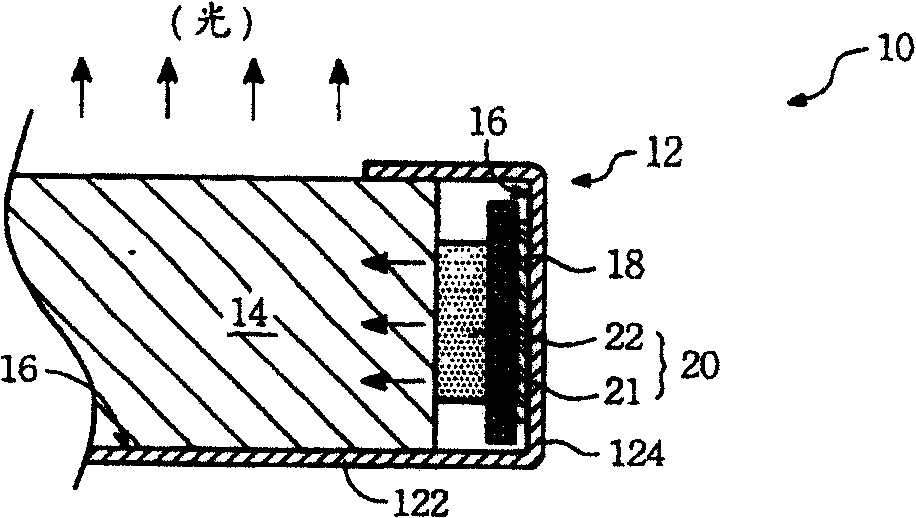

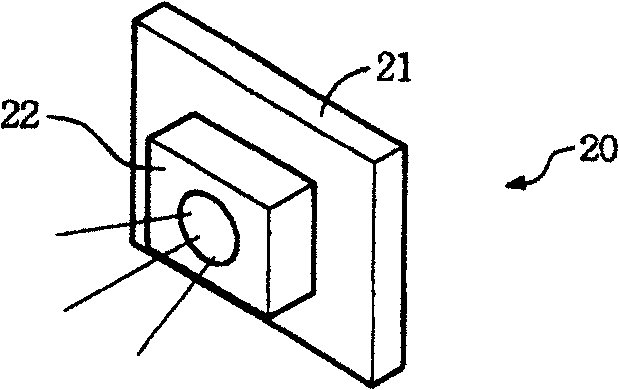

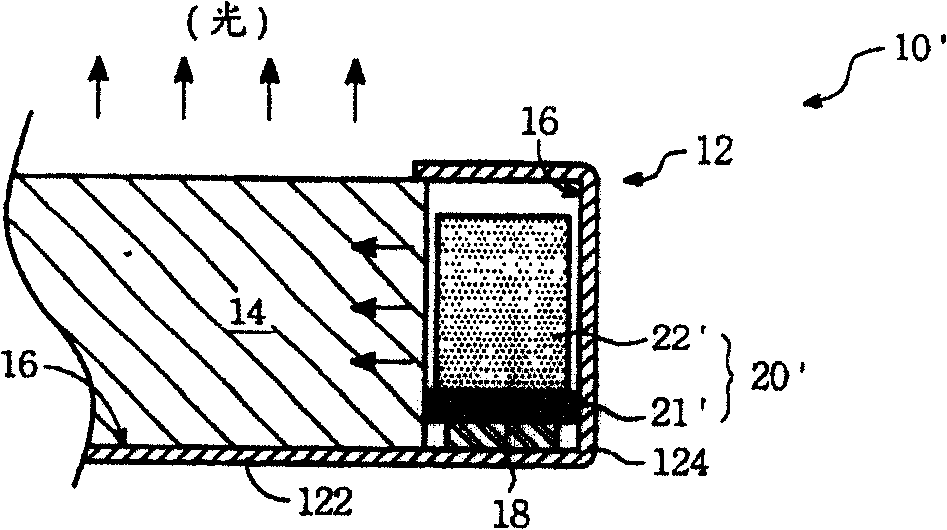

[0062] Please refer to Figure 3A and Figure 3B , is a side cross-sectional schematic diagram of a side-light incident type backlight module of the present invention. The backlight module 30 includes a substrate 321 , a light guide plate 34 , a light emitting diode 42 and a metal sheet 45 . Figure 3A It shows the situation that the light emitting diode 42 is not combined in front of the backlight module 30; Figure 3B A situation where the light emitting diode 42 has been combined in the backlight module 30 is shown.

[0063] Wherein, the substrate 321 has a first surface 321a, a second surface 321b and a hole 321c. The hole 321c passes through the first surface 321a and the second surface 321b. The substrate 321 is part of a back bezel 32 , and the base 32 further includes an extension portion 323 extending from the periphery of the substrate 321 .

[0064] The light guide plate 34 is disposed on the first surface 321a and does not cover the hole 321c. The light guide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap