Poly(vinyl alcohol) based film

A technology of polyvinyl alcohol and film, which is applied in medical science, bandages, absorbent pads, etc., and can solve problems such as unsatisfactory requirements and durability problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] 60 parts of PVA (a1) whose degree of saponification is 72mol%, 4% aqueous solution viscosity at 20°C is 6mPa·s, saponification degree is 98.5mol%, PVA with 4% aqueous solution viscosity at 20°C is 5mPa·s (a2) 40 parts, silicon dioxide (average particle diameter 6.4 μm) (B) 2 parts, trimethylol propane (C) 20 parts and water 690 parts are mixed, and obtaining the resin composition that solid content is 15%[ I] aqueous dispersion.

[0049] The aqueous dispersion of the obtained resin composition [I] was cast on a polyethylene terephthalate (PET) film with a feeder, and then dried at 90° C. for 10 minutes to obtain a 60 μm thick film. PVA type film.

[0050] The obtained PVA film can be completely dissolved in water at 20°C within 10 minutes, and the storage elastic modulus (α) at 20°C in a dry atmosphere is 4.0×10 7 Pa, the storage elastic modulus (β) at 20°C and 80% RH is 6.0×10 6 Pa, its ratio (α / β) is 6.7. In addition, the glass transition temperature of the obta...

Embodiment 2

[0062] Except using in embodiment 1 as PVA resin (a1) use saponification degree be 72mol%, the 4% aqueous solution viscosity at 20 ℃ is the PVA70 parts of 6mPa·s, the saponification degree used as PVA resin (a2) is Except for 30 parts of 98.5 mol % PVA having a 4% aqueous solution viscosity of 5 mPa·s at 20° C., the same procedure as in Example 1 was carried out to obtain a PVA-based film.

[0063] The obtained PVA film can be dissolved in water at 20°C within 10 minutes, and the storage modulus (α) at 20°C in a dry atmosphere is 3.3×10 7 Pa, the storage elastic modulus (β) under the condition of 20℃×80%RH is 4.3×10 6 Pa, its ratio (α / β) is 7.7. In addition, the glass transition temperature of the obtained PVA-based film was 8°C.

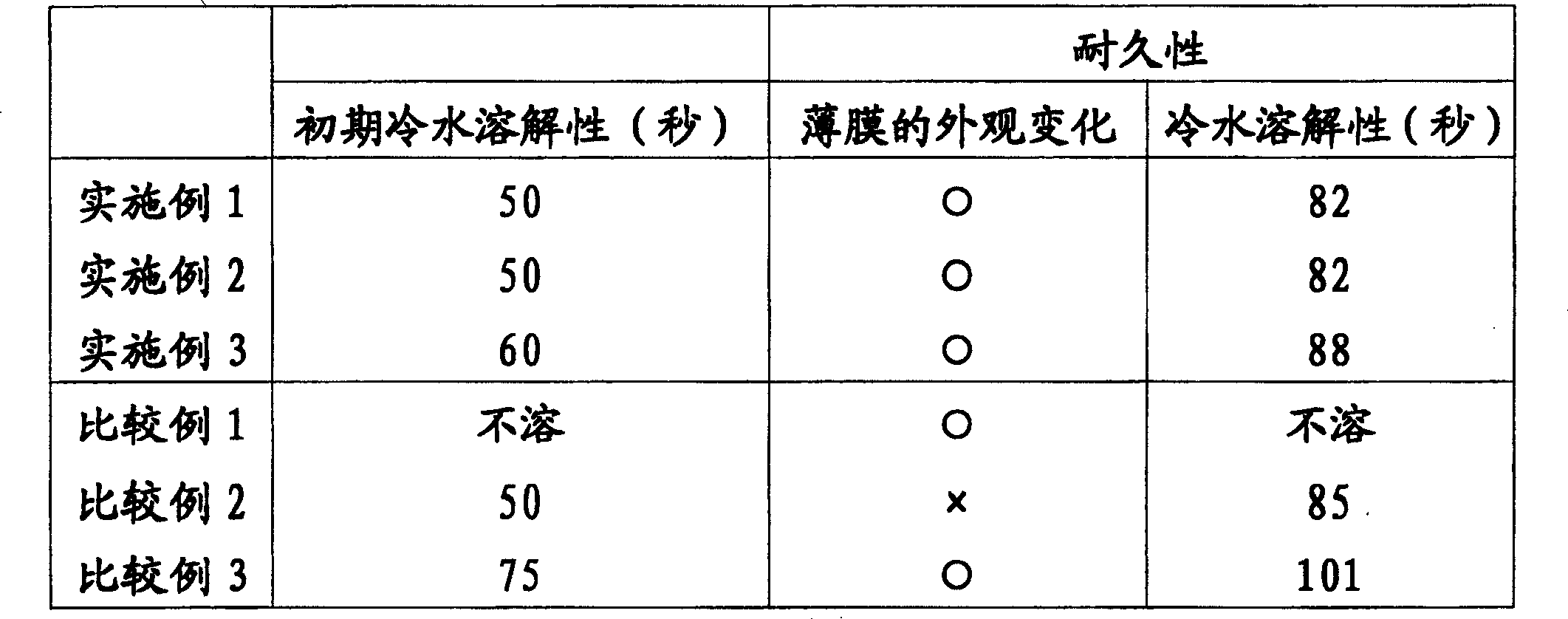

[0064] The same evaluation as in Example 1 was performed on the obtained PVA-based film. The results are shown in Table 1

Embodiment 3

[0066] In addition to using as the PVA resin (a1) in Example 1, the degree of saponification is 72mol%, and the viscosity of 4% aqueous solution at 20°C is 70 parts of PVA of 6mPa·s, and the PVA resin (a2) used is A PVA-based film was obtained in the same manner as in Example 1, except for 30 parts of PVA having a degree of saponification of 88 mol % and a viscosity of 5 mPa·s in a 4% aqueous solution at 20°C.

[0067] The obtained PVA film can be dissolved in water at 20°C within 10 minutes, and the storage elastic modulus (α) at 20°C in a dry atmosphere is 3.7×10 7 Pa, the storage elastic modulus (β) under the condition of 20℃×80%RH is 7.2×10 6 Pa, its ratio (α / β) is 5.1. In addition, the glass transition temperature of the obtained PVA-based film was 8°C.

[0068] The same evaluation as in Example 1 was performed on the obtained PVA-based film. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com