A spraying device of mortar or concrete and a spraying method ofthe mortar or concrete using the device

A spraying device and concrete technology, which is applied to mixers with rotary stirring devices, clay preparation devices, cement mixing devices, etc., can solve the problems of impossibility, large pressure feeding resistance, and difficult spraying construction, so as to prevent clogging and improve Continuity of delivery, easily adjustable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] Hereinafter, the implementation mode of the present invention will be described based on the drawings.

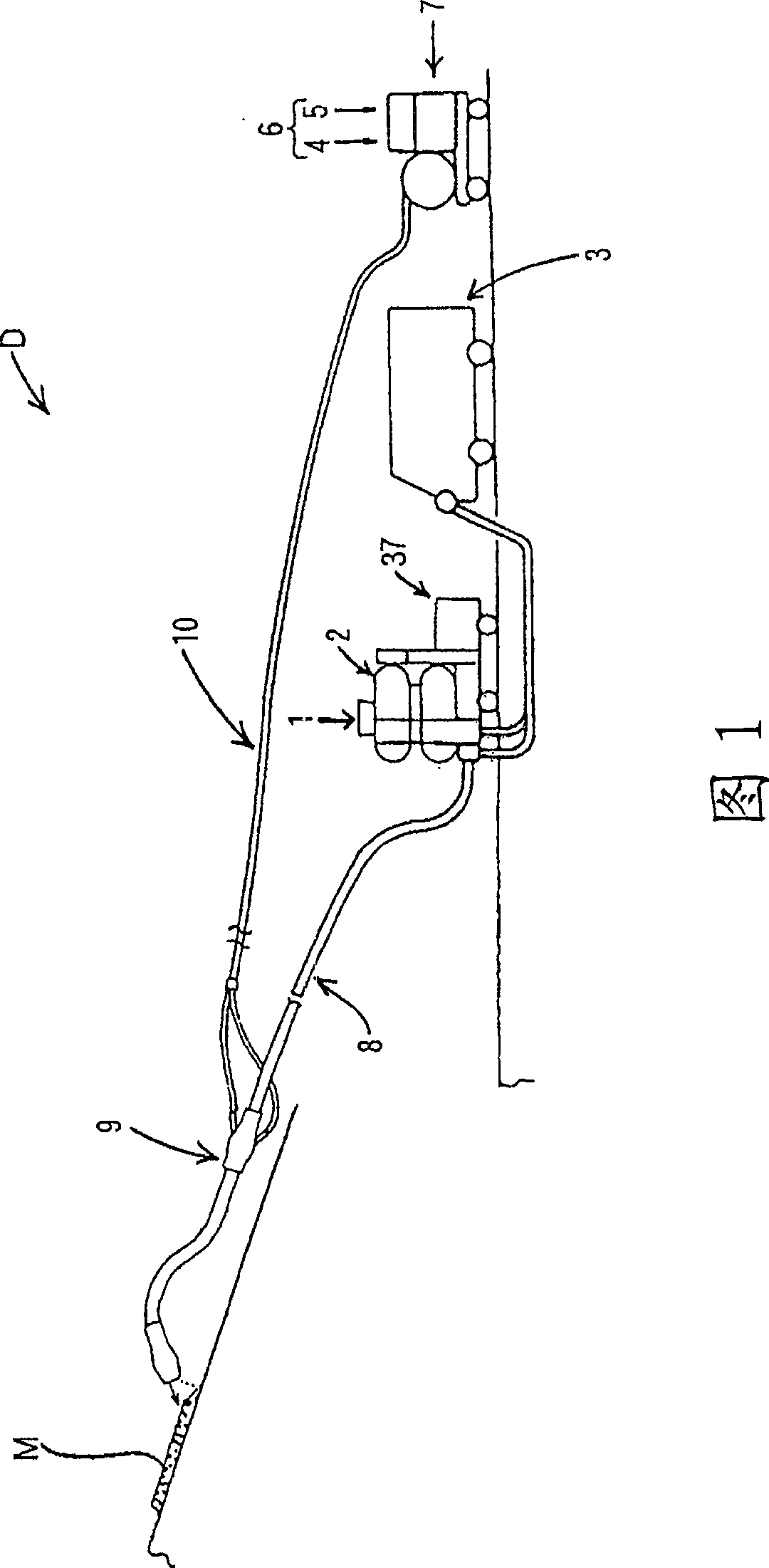

[0061] Figure 1 is an explanatory diagram schematically showing the construction of a mortar or concrete spraying device (hereinafter referred to as spraying device) D and method according to an embodiment of the present invention.

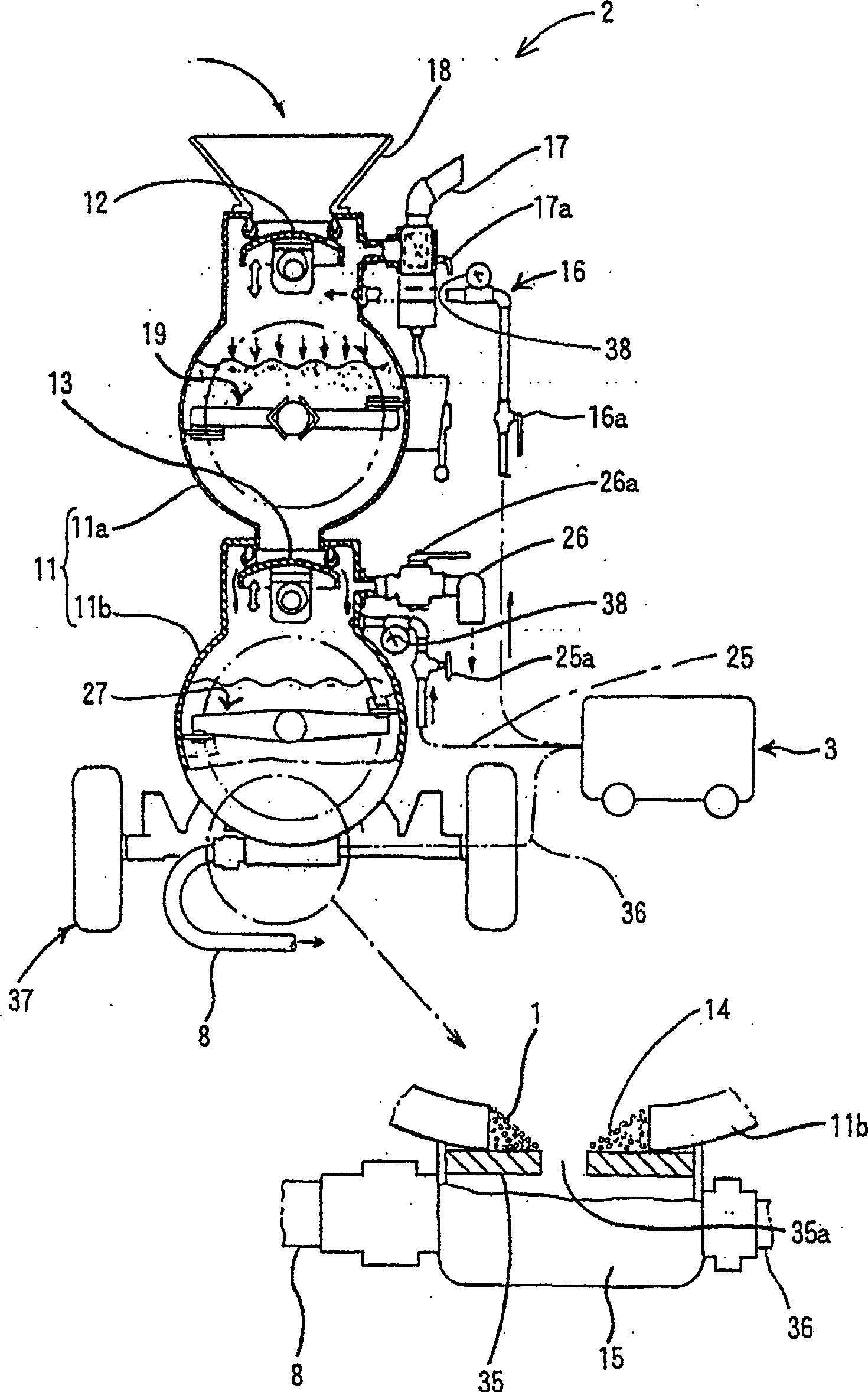

[0062] The spraying device D has: an aggregate pressing machine 2 for supplying aggregates (sand (fine aggregate) in the case of mortar M, and sand and gravel (thick aggregate) in the case of concrete) 1 Material supply mechanism; Air compressor 3, which is connected to the aggregate press 2 and used as a compressed air mechanism; Compression pump (such as piston pump, squeeze pump) 7, is used as a cement slurry delivery mechanism to deliver the mixed A cement slurry 6 made of cement 4 and water 5; a conveying pipe 8 is connected to the downstream side of the aforementioned aggregate press 2 and is provided with a cement slurry introduction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com