Lens barrel and lens module using same

A lens module and lens barrel technology, applied in the field of imaging systems, can solve the problems of difficulty in forming plastic lenses, difficult processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

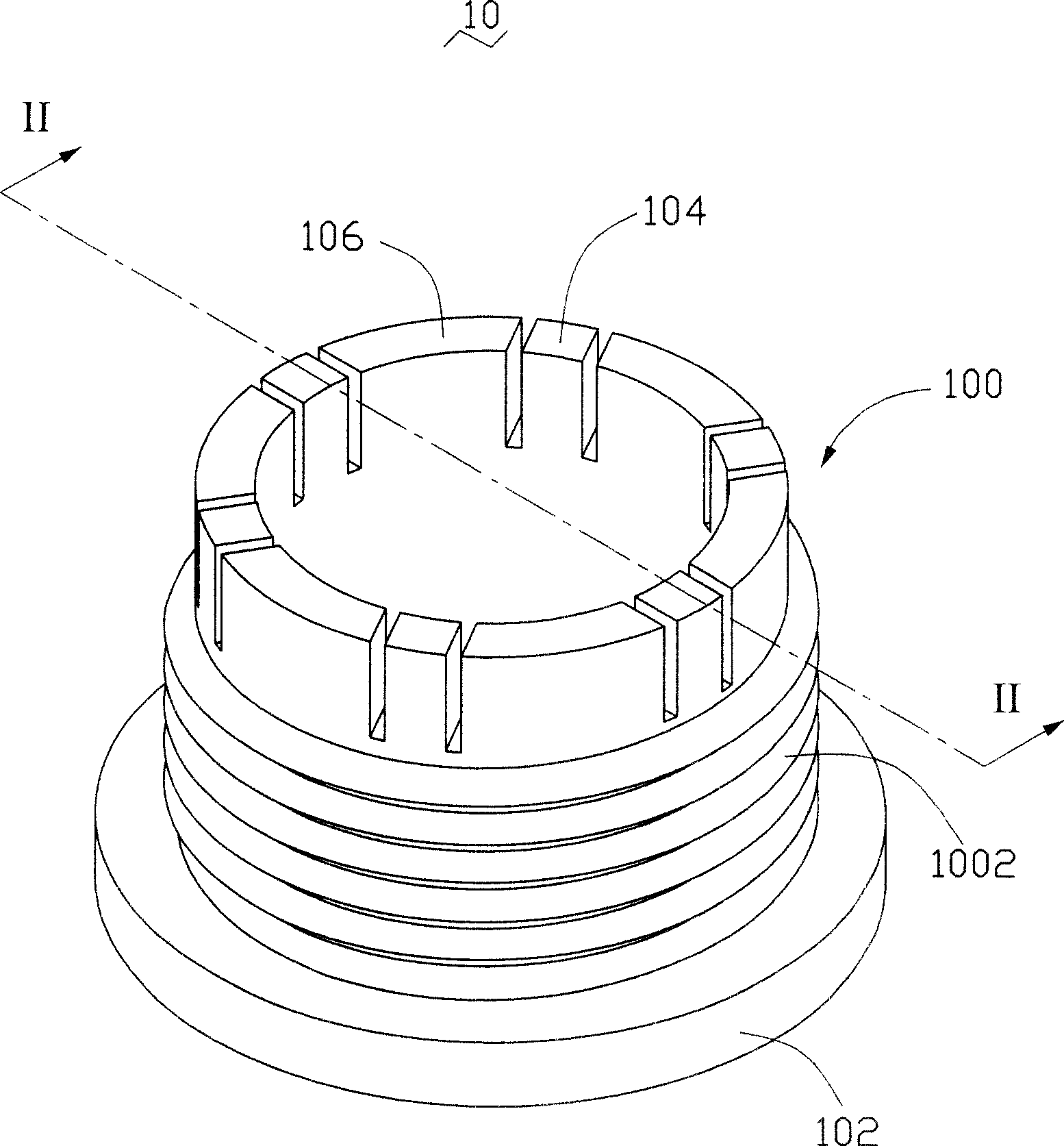

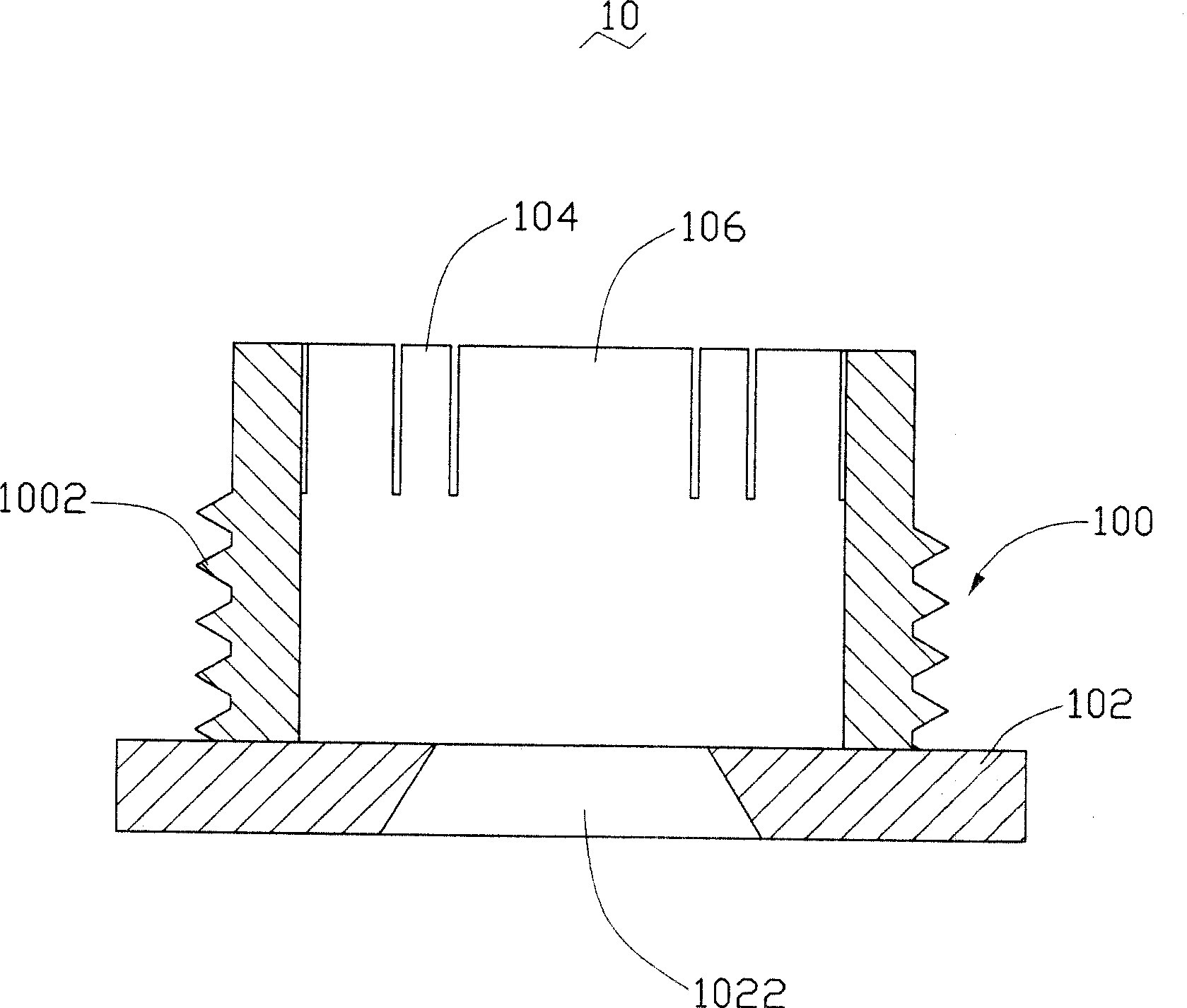

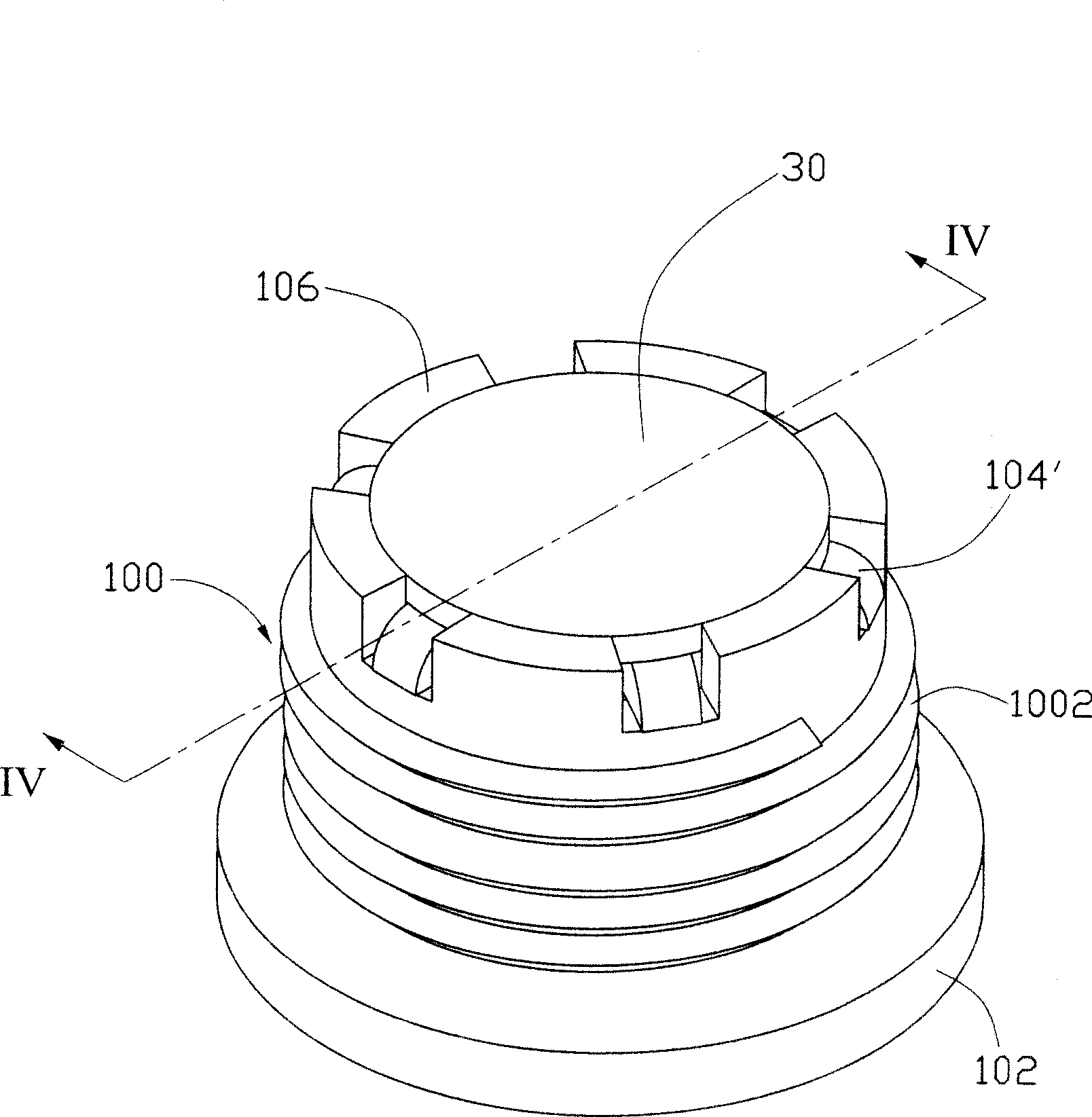

[0015] see figure 1 and figure 2 , a lens barrel 10 provided by an embodiment of the present invention includes a cylindrical body portion 100 , a front end 102 of the lens barrel, a plurality of bending portions 104 and a holding portion 106 .

[0016] The main body 100 has external threads 1002 formed on its outer surface. The main body 100 is used for accommodating optical elements such as lenses and filters, and its material can be engineering plastics such as polyethylene, polypropylene, polyvinyl chloride or polystyrene.

[0017] The front end 102 of the lens barrel is located at one end of the cylindrical main body 100 , the front end 102 of the lens barrel and the main body 100 are integrally formed, and it also has a funnel-shaped incident light whose diameter gradually changes along the thickness of the front end 102 of the len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com